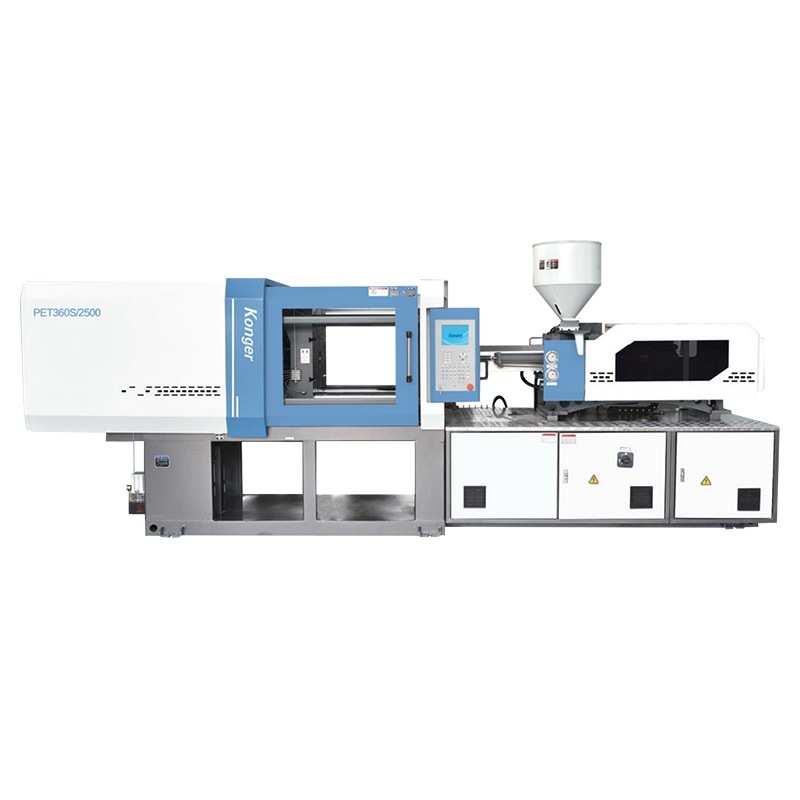

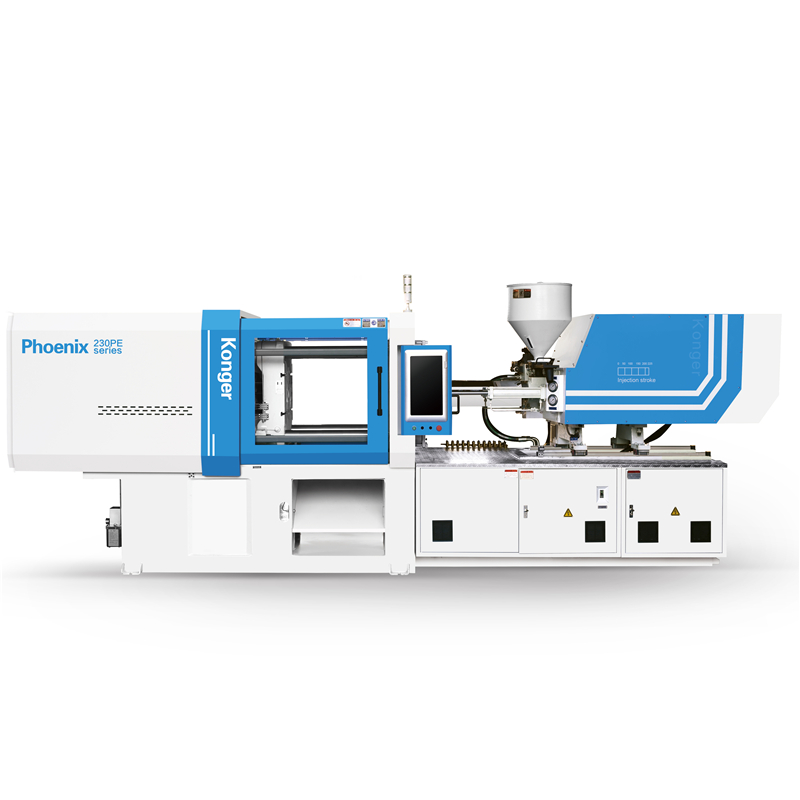

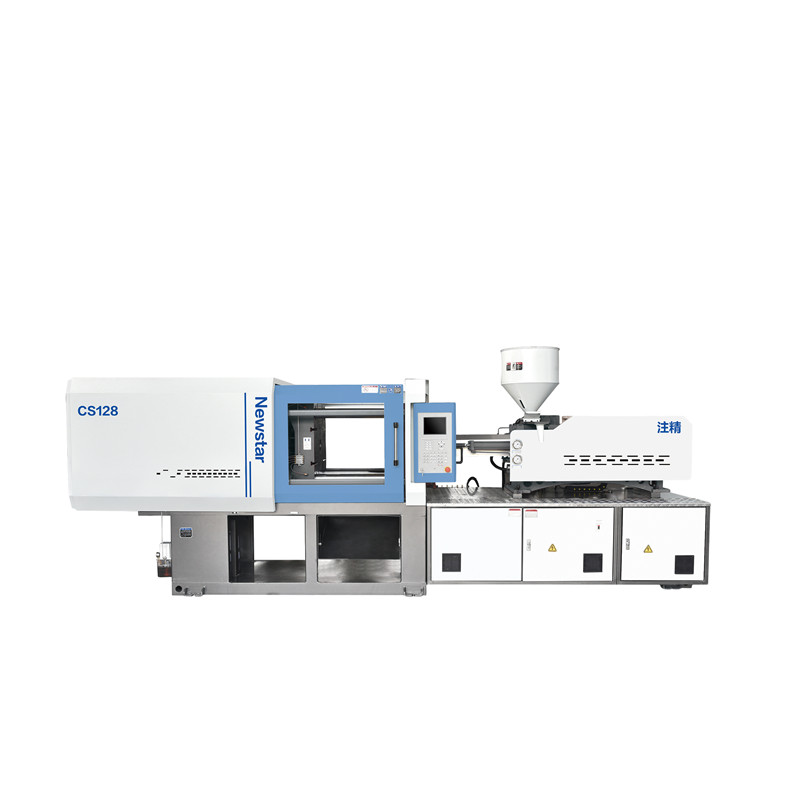

Best High Quality Compression Mold Machine Manufacturer - Newstar Series Plastic Injection molding machine – KONGER

Best High Quality Compression Mold Machine Manufacturer - Newstar Series Plastic Injection molding machine – KONGER

Best High Quality Compression Mold Machine Manufacturer - Newstar Series Plastic Injection molding machine – KONGER Detail:

FEATURES

APPLICATION

Konger produced injection molding equipment is widely used in auto parts, toys and gifts, daily necessities, PET, bottle embryos, home appliances, medical, electronic components and other industries.

SPECIFICATION

Cologge injection molding equipment is widely used in auto parts, toys and gifts, daily necessities, PET, bottle embryos, home appliances, medical, electronic components and other industries.

| SPECIFICATION | CN | CS128 | CS168 | ||||

| 400 | 633 | ||||||

| VB | cm3 | A | B | C | A | B | C |

| Injection Device | |||||||

| Screw Diameter | mm | 38 | 42 | 45 | 42 | 45 | 50 |

| Screw L/D Ratio | L/D | 21 | 19 | 18 | 23.5 | 22 | 19.8 |

| Shot Volume | cm3 | 192 | 235 | 270 | 311 | 357 | 441 |

| Injection Weight(PF) | g | 175 | 214 | 246 | 283 | 325 | 401 |

| Injection Rate | cm3/s | 108 | 130 | 138 | 138 | 160 | 196 |

| Injection Pressure | Mpa | 186 | 158 | 135 | 203 | 177 | 143 |

| Screw Speed | rpm | 220 | 200 | ||||

| Mold Closing Device | |||||||

| Clamping Force | KN | 1280 | 1680 | ||||

| Toggle Stroke | mm | 360 | 435 | ||||

| Space Between Tie-Bars WxH | mm | 410×410 | 460×460 | ||||

| Max.Mold Heightmm | mm | 160 | 180 | ||||

| Min.Mold Height | mm | 160 | 180 | ||||

| Ejector Stroke | mm | l20 | 135 | ||||

| Ejector Tonnage | KN | 30 | 50 | ||||

| Others | |||||||

| Max.Pump Pressure | Mpa | 16 | 16 | ||||

| Motor Power | KW | 14 | 18.5 | ||||

| Heater Power | KW | 7.55 | 12.3 | ||||

| Machine Dimensionm | m | 4.4×1.4×18 | 5.04×1.43×2.12 | ||||

| Oil Tank Capacity | L | 220 | 300 | ||||

| Machine Weightton | ton | 3.8 | 6 | ||||

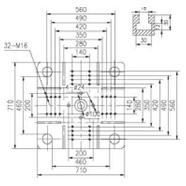

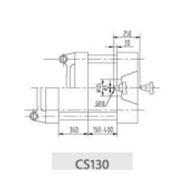

TEMPLATE SIZE

PLATEN DIMENSIONS

MOULD SPACE DIMENSIONS

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for Best High Quality Compression Mold Machine Manufacturer - Newstar Series Plastic Injection molding machine – KONGER , The product will supply to all over the world, such as: Orlando, UK, Swiss, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

Write your message here and send it to us