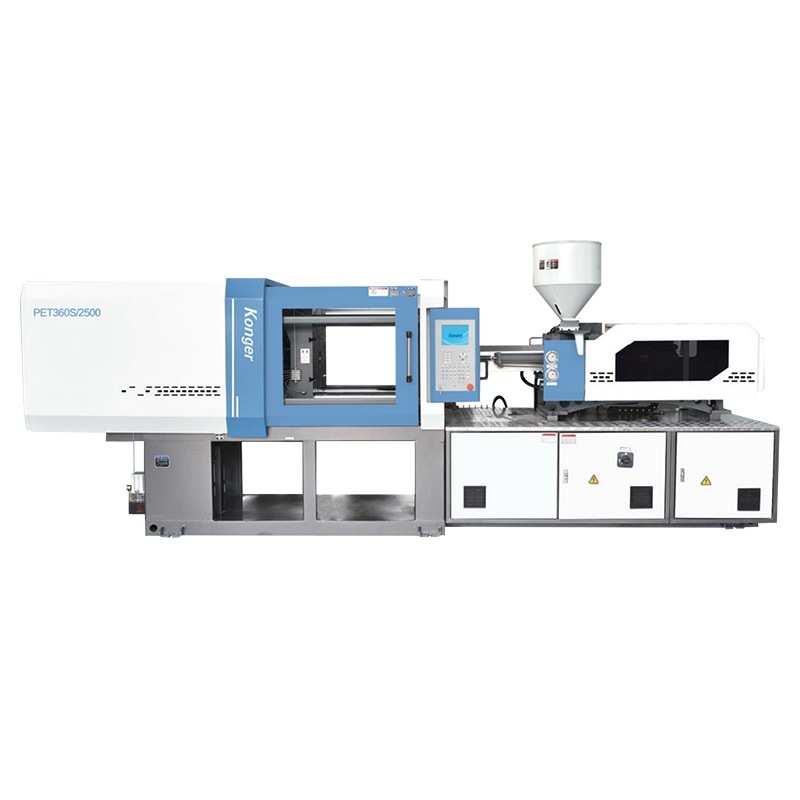

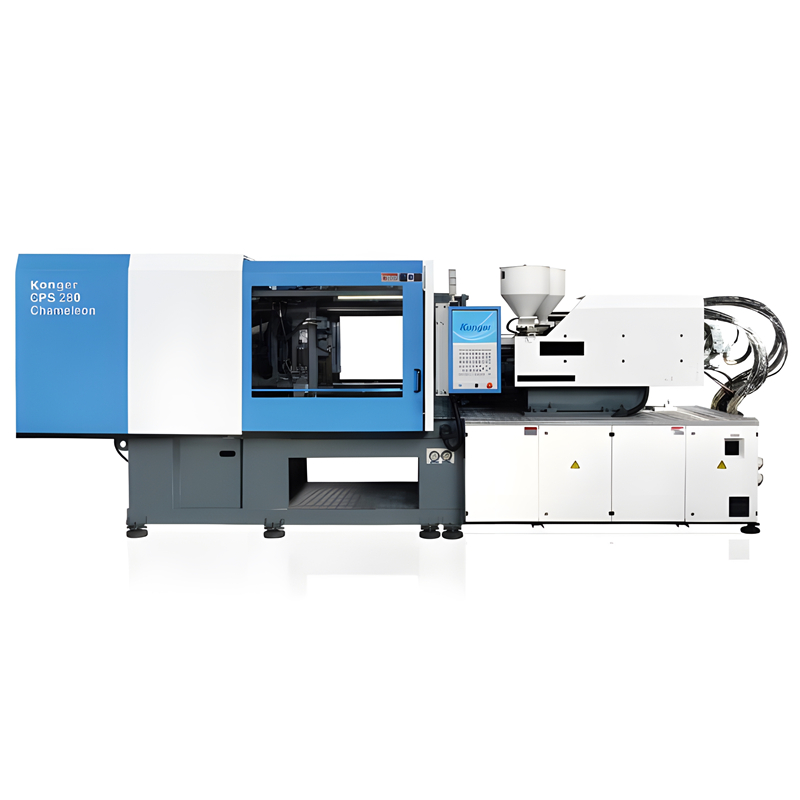

Best High Quality Molding Systems Factory - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER

Best High Quality Molding Systems Factory - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER

Best High Quality Molding Systems Factory - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER Detail:

Product advantages

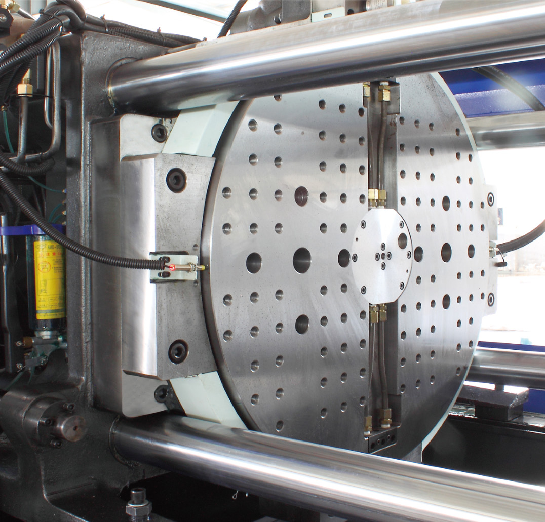

● Without touch the clamp when the turntable running.Can reduce fault because of the abrasion Preciseposition before moulds closed keep the moulds safety.

● Eject force be more stronger because double eject cylinder.

● Reciprocating 180 degree rotation table on movement plate. Can setup two moulds produce the two different color products.

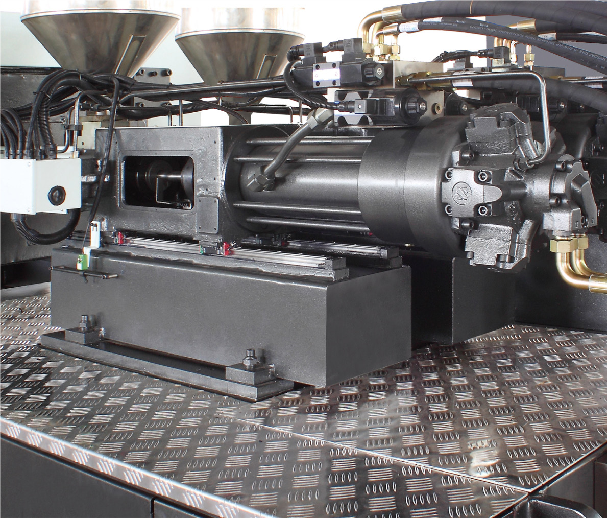

● Single injection cylinder keep injection more stable and precision.

● Low friction drag with precise guide because of injection linear guide.

● Special design all screw L:D=20:1 for all size injection unit setup easy changeable.Can match all customer special requirement.

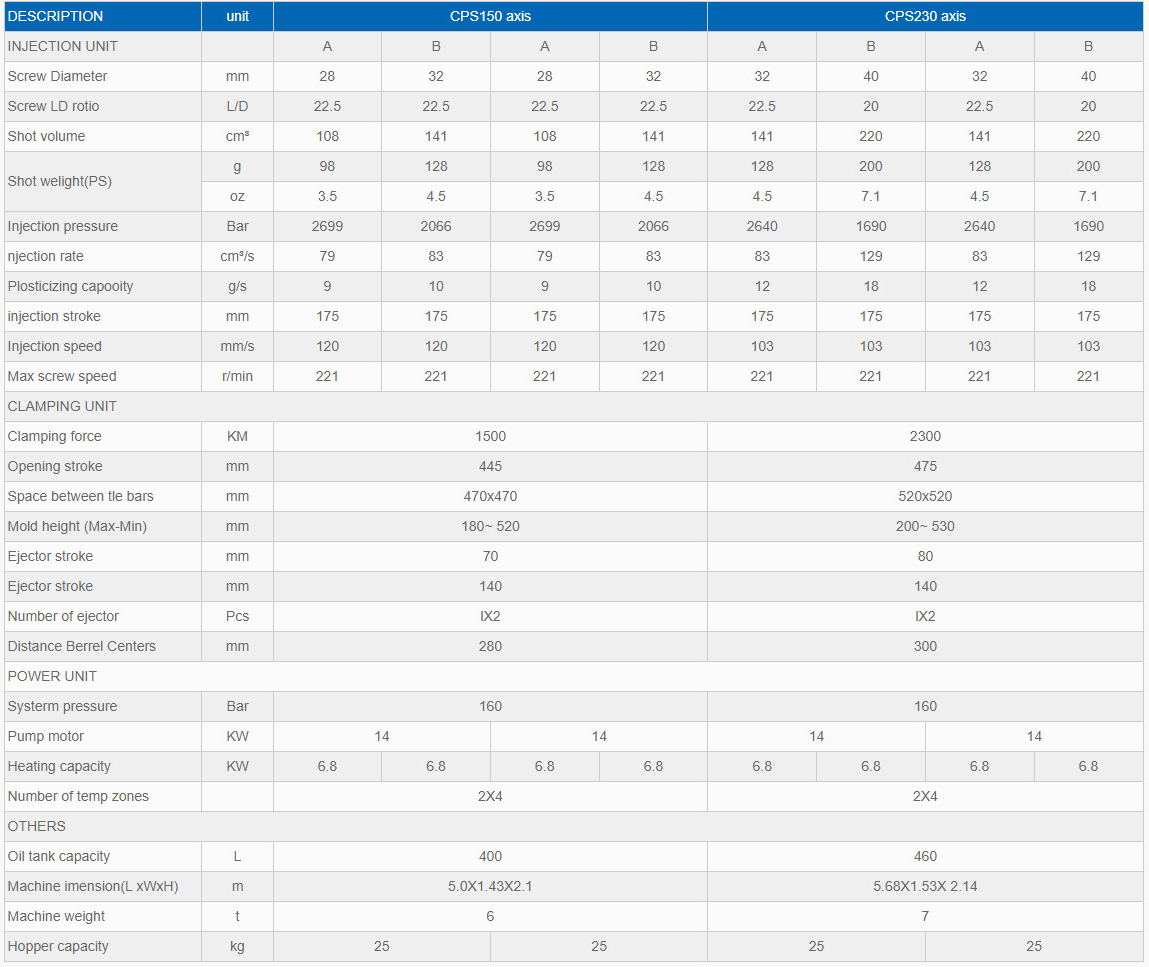

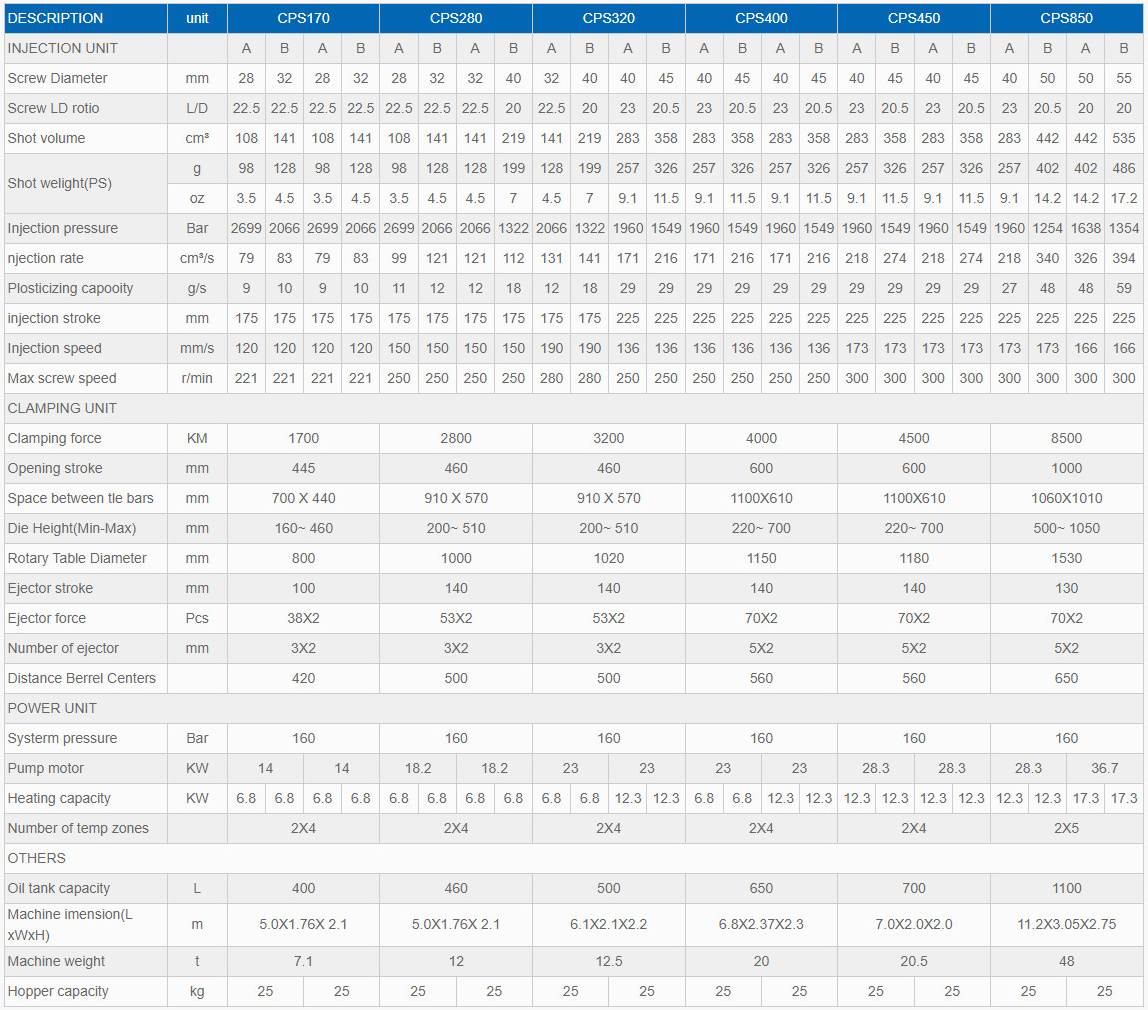

SPECIFICATION

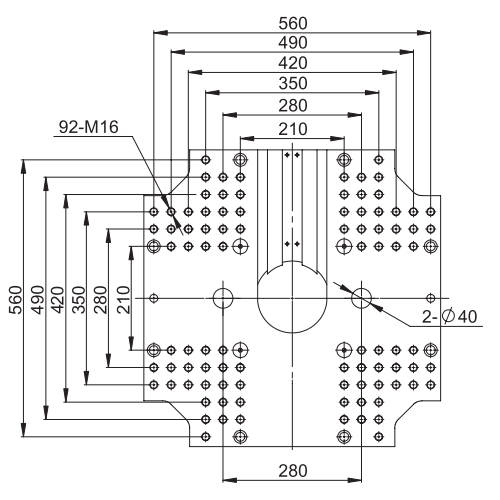

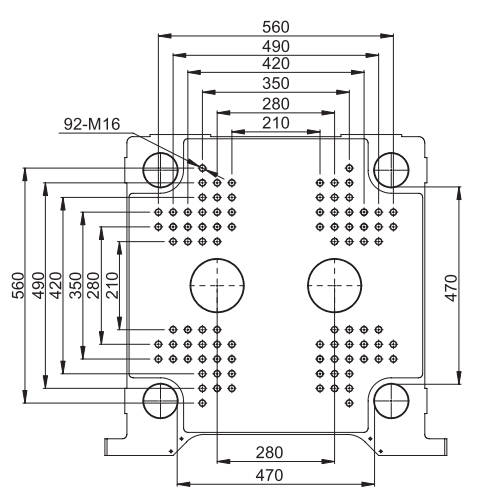

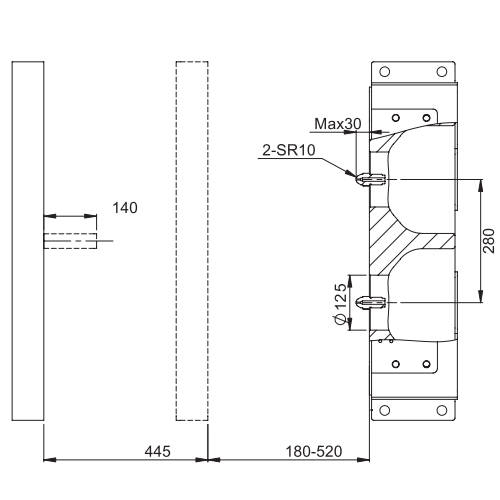

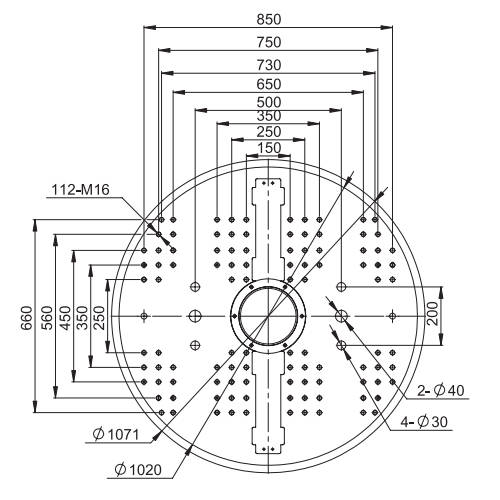

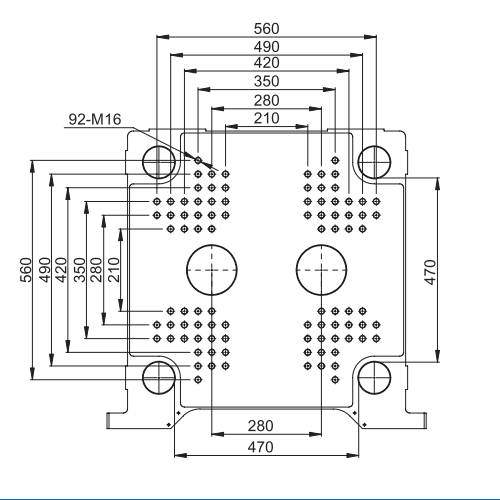

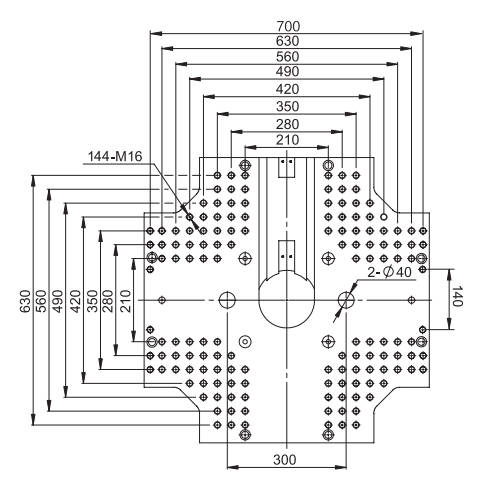

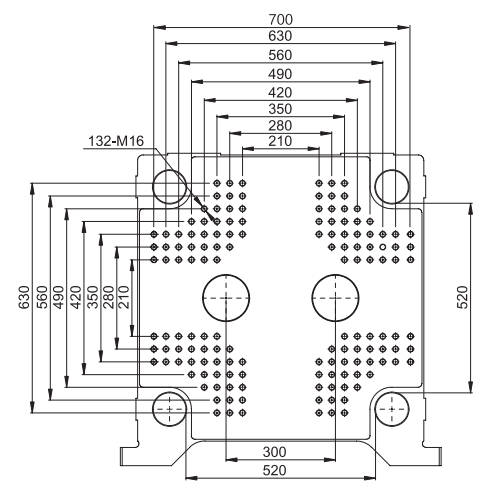

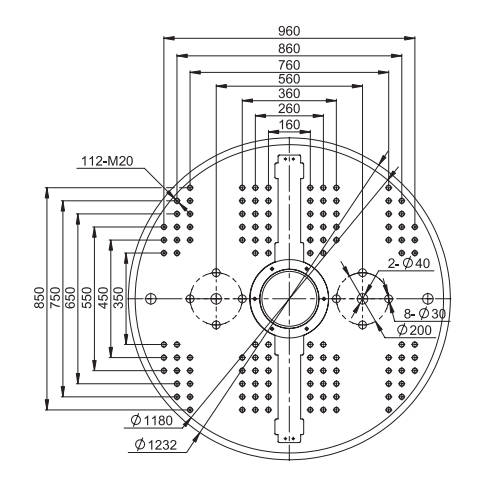

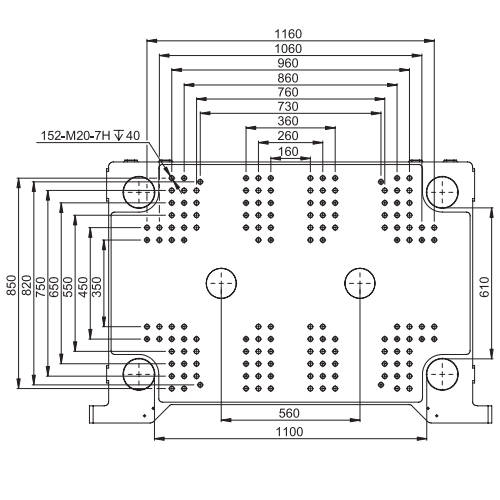

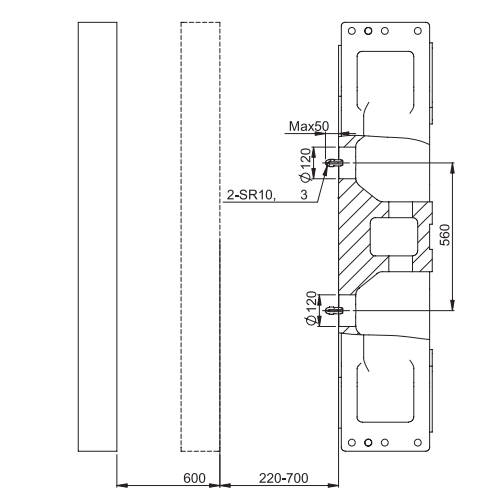

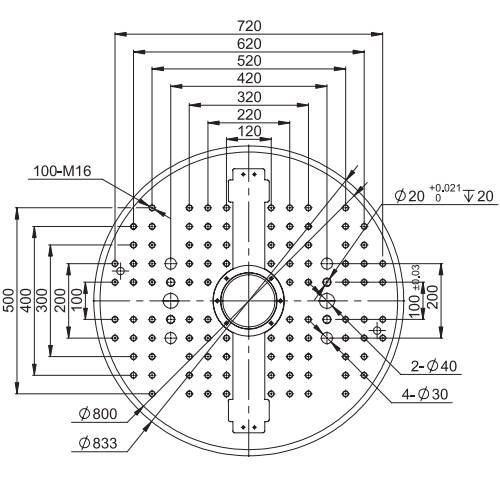

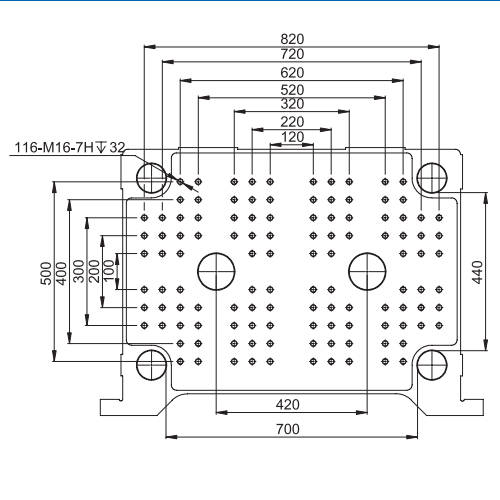

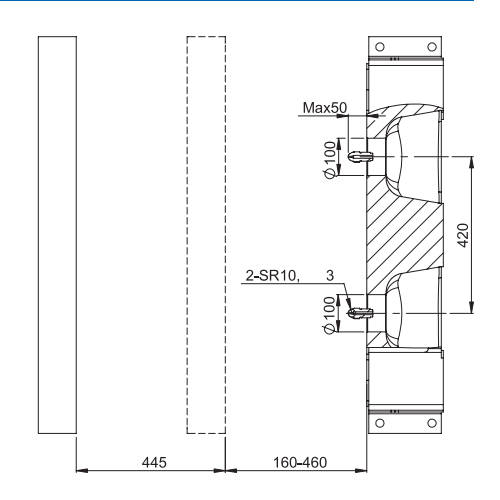

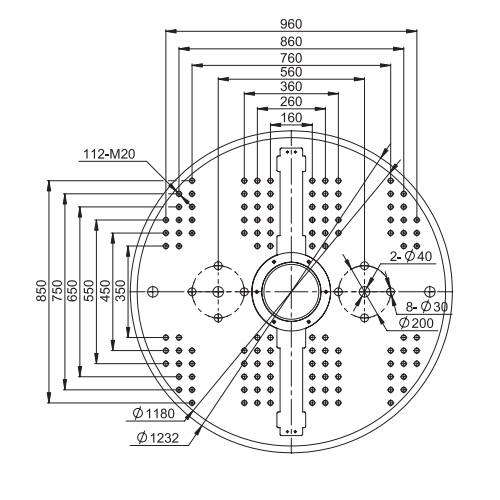

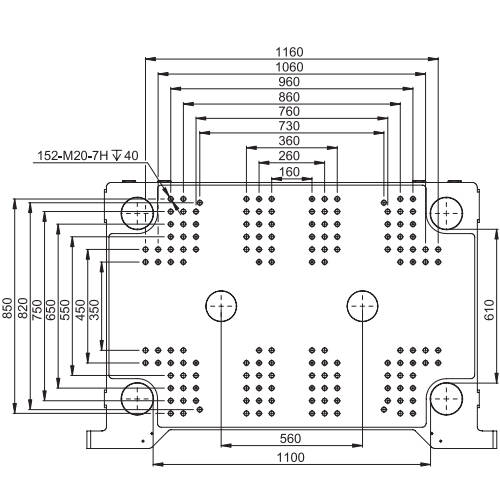

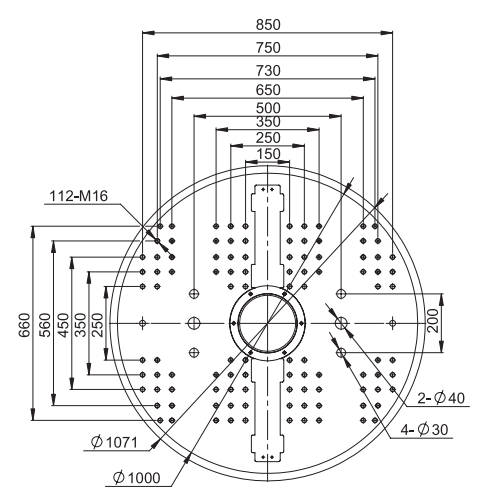

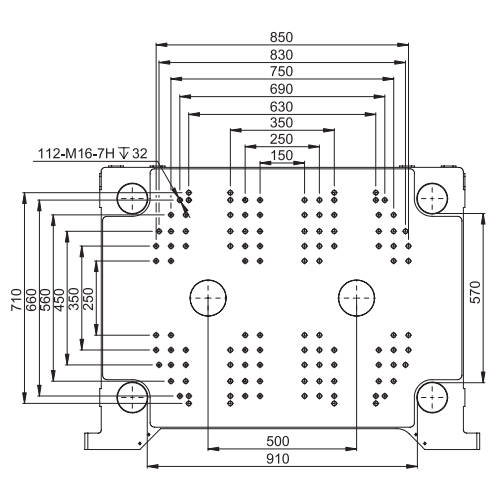

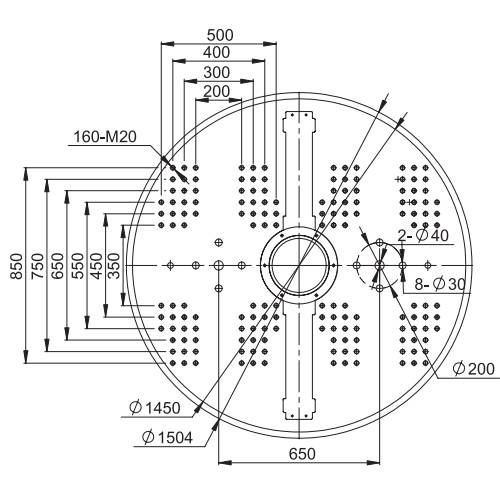

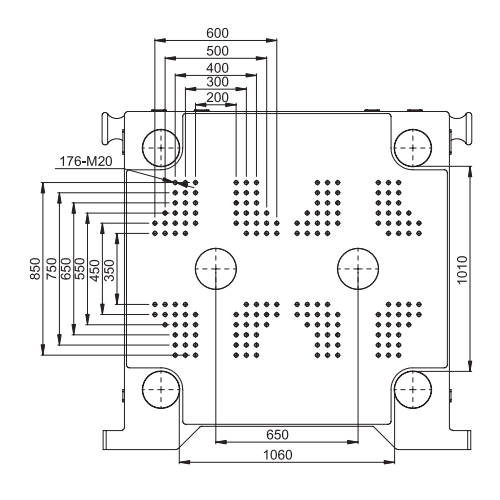

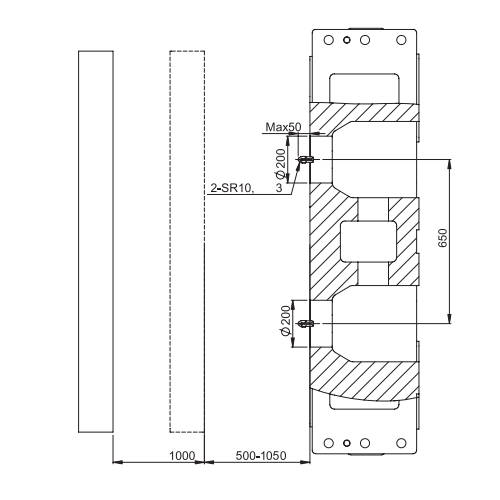

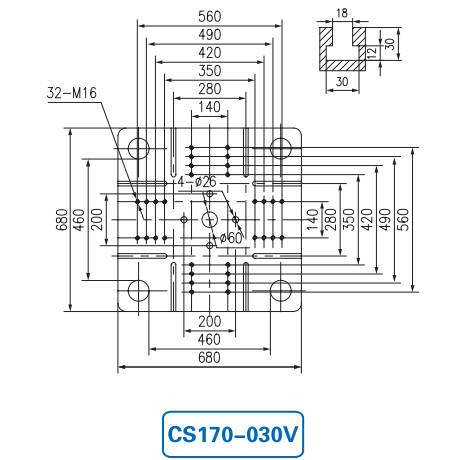

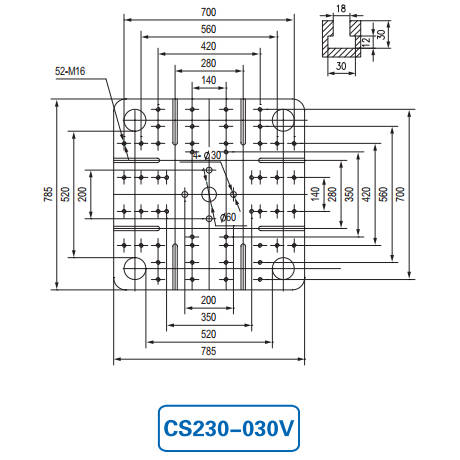

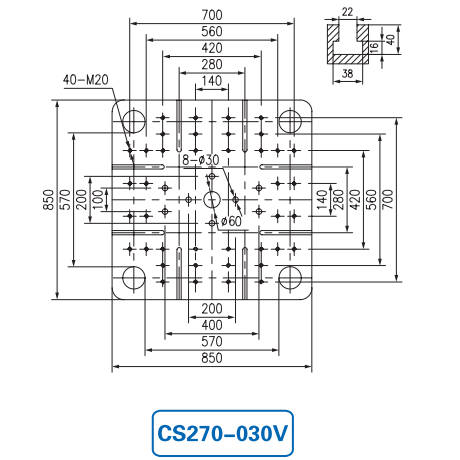

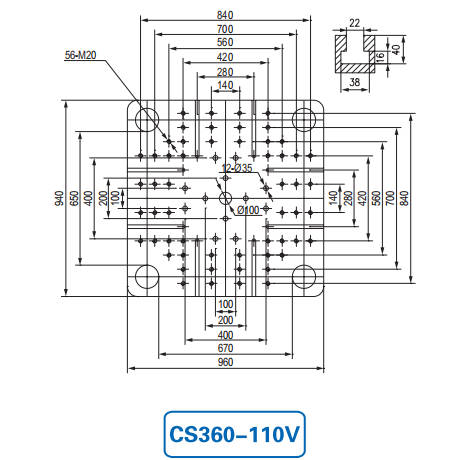

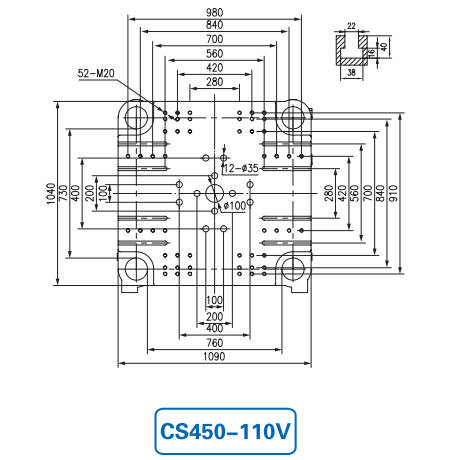

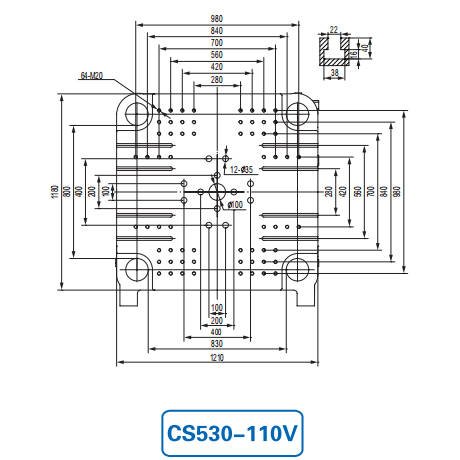

Template plane diagram

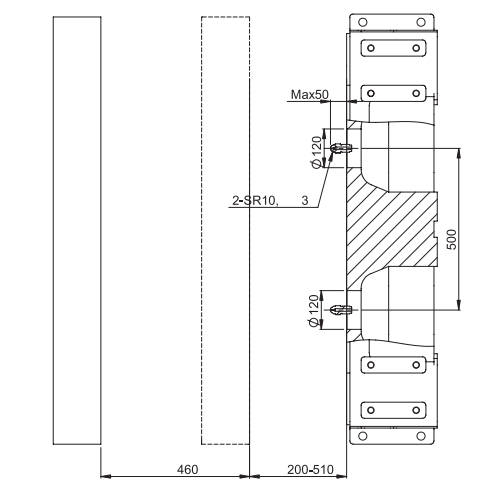

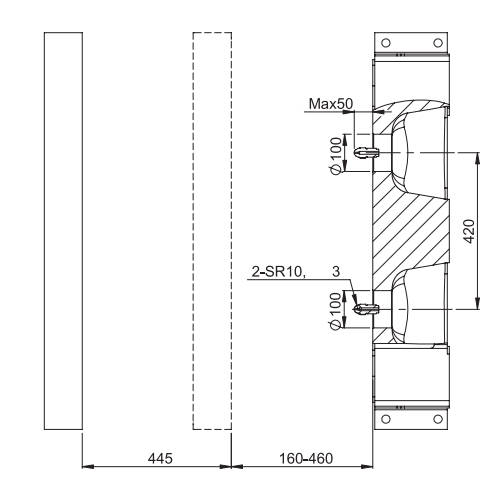

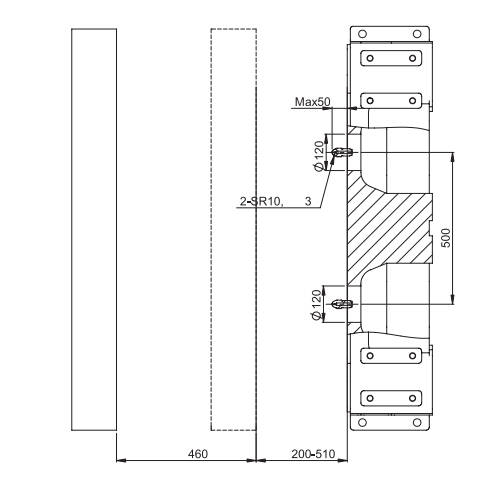

L model clean two color

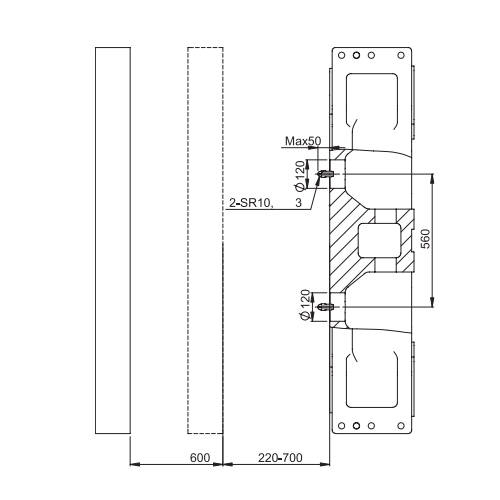

● Second injection unit setup on plate can save the grand area for customer.

● Reciprocating 180 degree rotation table on movement plate.Can setup one moulds produce the two different color products.

●Efficiently servo gear transmission structure keep rotating high speed with stable and precise position.

● Multi-plate design can suit for all products requirement rotation table or rotation shaft.

● Without touch the clamp when the turntable running. Can reduce fault because of the abrasion. Precise position before moulds closed keep the moulds safety.

CS230-030V

SATISFACTION

| DESCRIPTION | unit | CS170-030V | CS230-030V | CS270-030V | CS360-110V | CS450-110V | CS530-110V | ||||||||||||||||||||||||

| International size rating | cm³ | 633 | 130 | 824 | 130 | 1085 | 130 | 2418 | 358 | 2987 | 358 | 4155 | 358 | ||||||||||||||||||

| INJECTION UNIT | UNIT | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B |

| Screw Diameter | mm | 42 | 45 | 50 | 22 | 25 | 45 | 50 | 55 | 22 | 25 | 50 | 55 | 60 | 22 | 22 | 65 | 70 | 75 | 35 | 38 | 70 | 75 | 80 | 35 | 38 | 80 | 85 | 90 | 35 | 38 |

| Screw L:D ratio | L/D | 23.5 | 22 | 19.8 | 20 | 20 | 23.4 | 21 | 19.1 | 20 | 20 | 25.2 | 22.9 | 2l | 20 | 20 | 22.5 | 21 | 19.6 | 22.8 | 21 | 22 | 20.5 | 19.2 | 22.8 | 21 | 22.3 | 21 | 19.8 | 22.8 | 21 |

| Shot volume | cm³ | 311 | 357 | 401 | 38 | 49 | 397 | 490 | 593 | 38 | 49 | 530 | 641 | 763 | 38 | 38 | 1161 | 1347 | 1546 | 163 | 192 | 1500 | 1723 | 1960 | 163 | 192 | 2210 | 2495 | 2797 | 163 | 192 |

| Shot weight(PS) | g | 283 | 325 | 441 | 35 | 45 | 362 | 446 | 540 | 35 | 45 | 482 | 583 | 694 | 35 | 35 | 1057 | 1226 | 1407 | 148 | 175 | 1365 | 1568 | 1784 | 148 | 175 | 2011 | 2270 | 2545 | 148 | 175 |

| Injection rate | cm³/s | 138 | 160 | 196 | 40 | 51 | 124 | 154 | 186 | 40 | 51 | 187 | 227 | 270 | 40 | 40 | 337 | 368 | 422 | 90 | 104 | 335 | 384 | 437 | 90 | 104 | 442 | 499 | 560 | 90 | 104 |

| Injection pressure | Mpa | 203 | 177 | 143 | 342 | 265 | 207 | 168 | 138 | 342 | 265 | 205 | 169 | 142 | 342 | 342 | 208 | 179.6 | 156 | 219 | 186 | 199 | 173 | 152 | 219 | 186 | 188 | 167 | 149 | 219 | 186 |

| Max screw speed | r/min | 200 | 260 | 175 | 260 | 185 | 260 | 155 | 205 | 150 | 205 | 120 | 205 | ||||||||||||||||||

| CLAMPING UNIT | |||||||||||||||||||||||||||||||

| Clamping force | KN | 1700 | 2300 | 2700 | 3600 | 4500 | 5300 | ||||||||||||||||||||||||

| Opening stroke | mm | 435 | 475 | 540 | 615 | 740 | 840 | ||||||||||||||||||||||||

| Space between tie bar | mm | 460 X 460 | 520 X 520 | 570 X 570 | 670 X 650 | 760 X 730 | 830 X 800 | ||||||||||||||||||||||||

| Max.mold height | mm | 520 | 530 | 580 | 680 | 780 | 830 | ||||||||||||||||||||||||

| Min.mold height | mm | 180 | 200 | 200 | 250 | 280 | 350 | ||||||||||||||||||||||||

| Ejector stroke | mm | 135 | 140 | 150 | 160 | 200 | 240 | ||||||||||||||||||||||||

| Ejector force | KN | 50 | 70 | 70 | 100 | 150 | 150 | ||||||||||||||||||||||||

| POWER UNIT | |||||||||||||||||||||||||||||||

| Systerm pressure | Bar | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||||||||||||||||

| Pump motor | KW | 18.2 | 11 | 23 | 11 | 23.8 | 11 | 36.7 | 11 | 44 | 11 | 23+28.3 | 11 | ||||||||||||||||||

| Heating capacity | KW | 12.3 | 5.9 | 14.8 | 5.9 | 16.8 | 5.9 | 24.6 | 7.55 | 28.7 | 7.55 | 32.6 | 7.55 | ||||||||||||||||||

| OTHERS | |||||||||||||||||||||||||||||||

| Oil tank capacity | L | 340 | 400 | 430 | 650 | 700 | 800 | ||||||||||||||||||||||||

| Machine dimension(L xWxH) | m | 5.28 X 1.43 X 2.9 | 5.68 X 1.5 X 3.1 | 6.0 X 16 X 3.8 | 7.1 X 1.9 X 3.8 | 7.84 X 1.88 X 4.15 | 8.74 X 2.05 X 4.2 | ||||||||||||||||||||||||

| Machine weight | t | 6.3 | 7.3 | 9.2 | 13.9 | 17.5 | 21.5 | ||||||||||||||||||||||||

Template planediagram

Product detail pictures:

Related Product Guide:

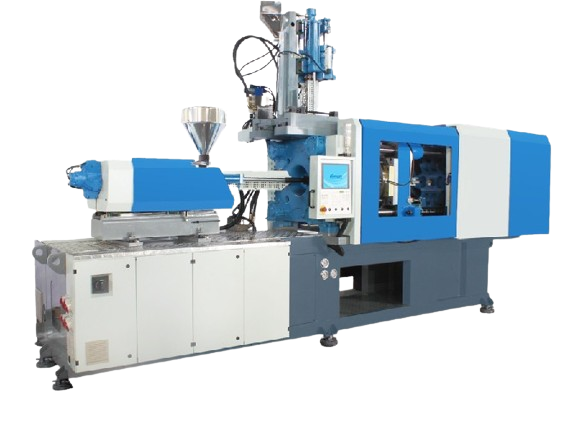

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Best High Quality Molding Systems Factory - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Kenya, US, Algeria, We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.