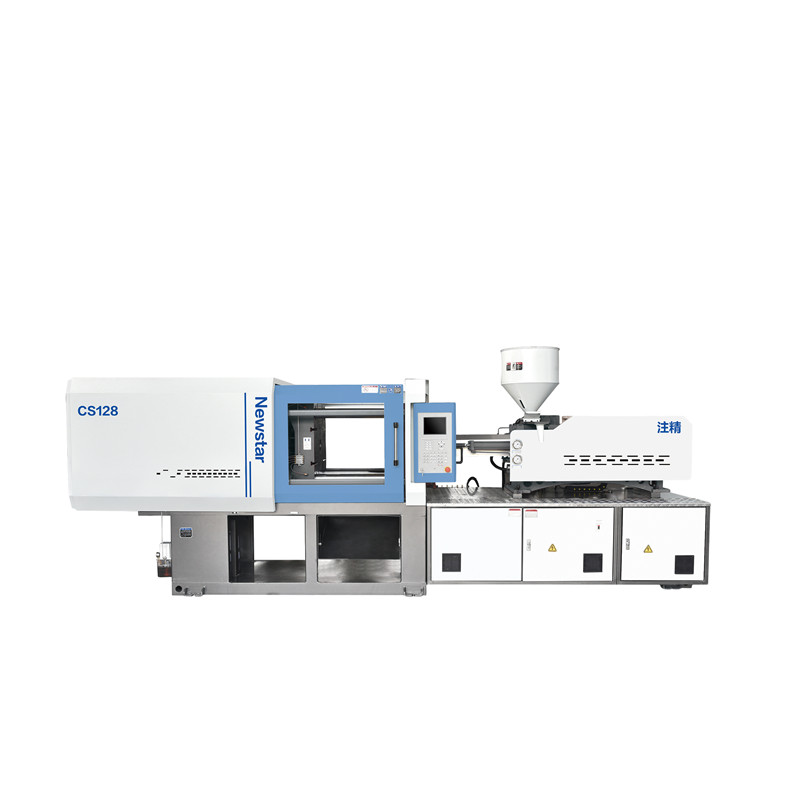

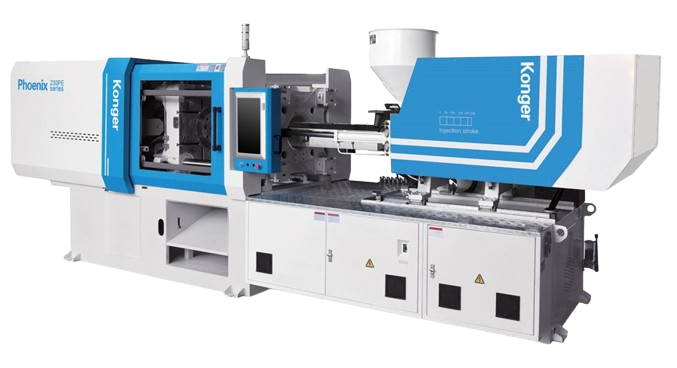

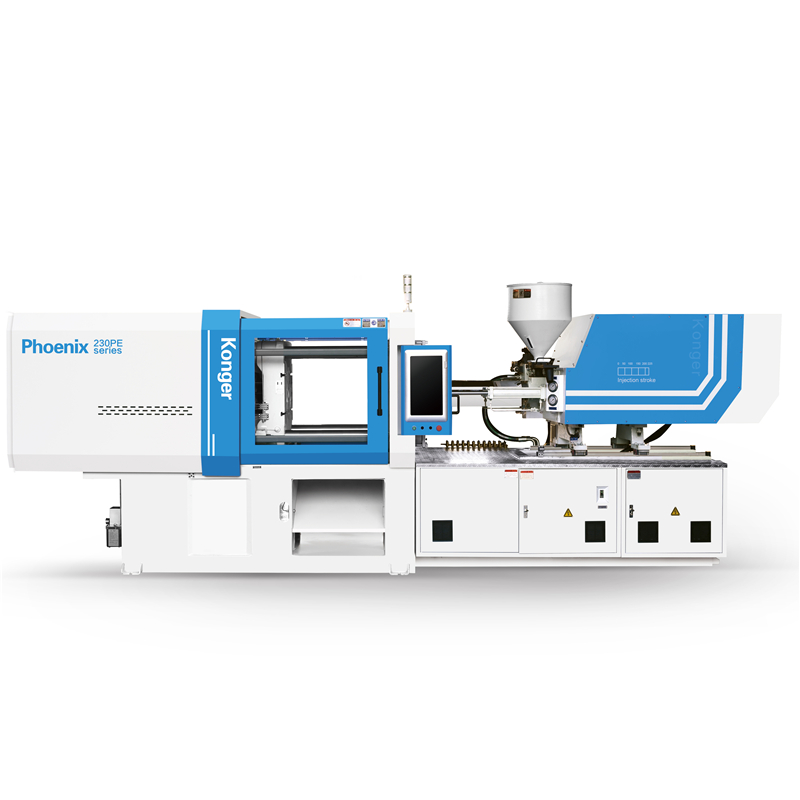

Best High Quality Multiplas Injection Molding Machine Manufacturers - Phoenix-PE Series Plastic Injection Molding Machine – KONGER

Best High Quality Multiplas Injection Molding Machine Manufacturers - Phoenix-PE Series Plastic Injection Molding Machine – KONGER

Best High Quality Multiplas Injection Molding Machine Manufacturers - Phoenix-PE Series Plastic Injection Molding Machine – KONGER Detail:

Product advantages

Excellent Molding Produce Valvestability

The servo driving system has its pressure and flow under close loop control; and compared with traditional injection molders, its molding repetition precision is improved substantially.

Constant Oil Temperature

The serve motor output hydraulicoil proportionately to prevent excessive heat.lt can achieve substantial water saving even without cooling.

Substantial Energy Saving

Uhder the same conditions, it can save 20%-80% energy compared with traditional constant delivery pump injection molders.

● The Phoenix series perfectly combines electric and hydralalic system. The Modular Design can also achieve movement

synchronization. Therefore, the high performance of the machine makes it more competitive in the market.

● Machine with an efficienct reaction, high-speed, high response, it can achieve multi-functional simultaneous operation and

improve production efficiency.

● Optimized machine toggle structure, the opening and closing mold is smooth and fast, and the working life more longer.

● Reliable shooting mechanism, screw with professional plasticization configuration, high-precision, closed-loop temperature

controlling.

Product Description

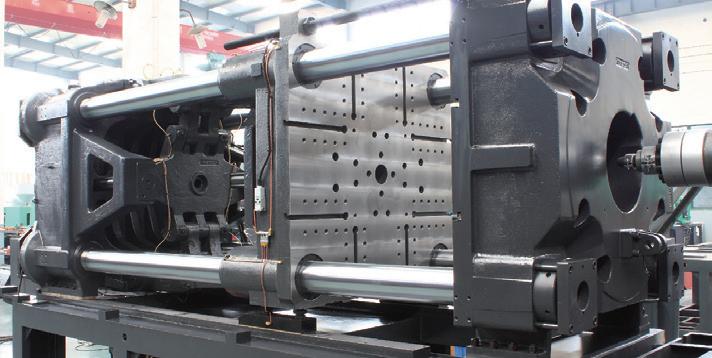

● The Tie-Bars surface use hard chrome treatment, it’ s wearresistant and anticorrosion.

● With finite element technical analysis platen design, optimizing the platen structure, reducing the deformation and cracking of the platen, enhancing the precision of clamping, and reducing mold loss.

● Automatic centralizing lubrication system, reduces maintenance costs.

● Sgchronous gear mold adjustment, realize auto mold adjust.

● Optimized machine toggle structure, the opening and closing mold is smooth and fast, and the working life more longer.

● Unique single-cylinder injection mechanism, solving the phenolmenon of single -cylinder oil leakage in the market, improving the injection accuracy and injection synchronization.

● Optimized screw design, suitable for a variety of raw materials, a variety of screw configurations to meet the needs of different products.

● Increasing the power system, the whole machilne is faster, the injection speed is about 150mm/s.

● The injection unit can be installed the ball screw structure to realize the full electric injection, the injection speed can reach to 300-1000mm/s.

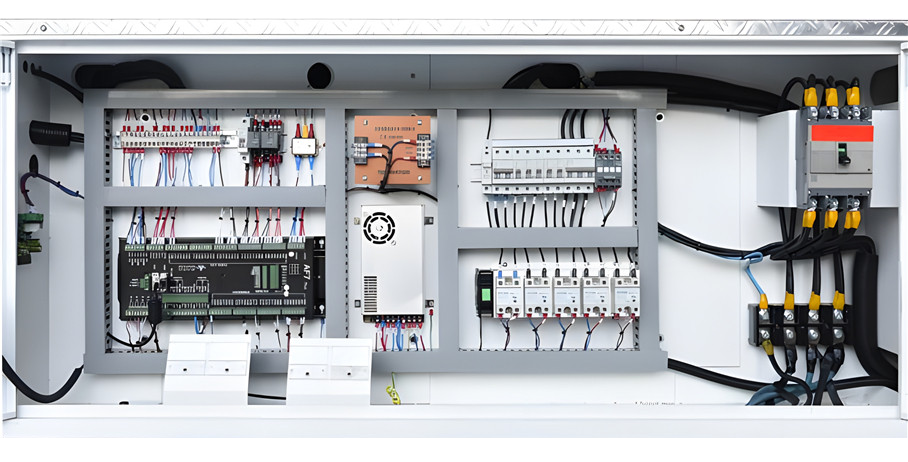

● The controller adopts a special computer of an injection molding

machine. The response is faster and the control accuracy is better.

● The panel is a color touch screen, and the clear screen operation is

more handy.Support for multiple languages.

● System with dual-core microprocessors makes it high-speed, anti-noise, low power consumption.

● USB interface can be updated or backup system parameters.

● Internal inspection Ethernet interface, convenient connection.

● Smart security features like page prompts, Provide maintenance tips and warranty.

● Injection pressure, velocity, end and holding pressure curve display graphical.

● With a record 120 groups and 120 groups to modify alarm recording function.

● Computer boot self-test function and mechanical failure alarm.

● I / O simulation capabilities that enable online analog input and output points.

● Supports simultaneous monitoring of multiple machines through anoffice computer, corporate managers may. differ according to theproduction process, production resources planning.

● User-friendly design layout manipulation.

● Servo drives can achieve a variety of control methods of digital control and analog control.

● Multiple closed-loop monitoring device as standard transfer mode electric eye, the analyte electric eye, speed electric eye, etc.

Phoenix/PE series

● Storage parts adopted high response, low inertial servo motor with belt wheel drive screw structure, Not only can improve accuracy, but also energy saving. It can achieve compound action, shorten the molding cycle;

● Compared with the traditional injection molding machine, Phoenix /PE series has a faster injection speed, which can reach about 150mm/s. It can solve some defects of traditional injection molding machines in the injection process (such as water ripples, etc.);

● With finite element technical analysis platen design, optimizing platen structure, dedicated to fast operation, especially suitable for precision mold usage;

● Adopting modular design, the same mold locking mechanism can combine with different specifications of injection mechanisms and screw.

Q; Are you a manufacture or a trading company?

A: We are a manufacturer in Ningbo city, Zhejiang Province, China

Q,: What’s your payment term?

A: 30% TT as deposit, 70% TT before shipment, and other payments can also be negotiated

Q: What’s your delivery time?

A: within 30 working days after received deposit.(U98TS-U438TS)

within 60 working days after received deposit.(U508TS-U78OTS)

within 90 working days after received deposit.(U1080TS-U1850TS)

within 120 working days after received deposit.(U2400TS-U3400TS)

Q: What should l do if there is a quality problem?

A: We have guarantee 1 year for machine, 6 months for screw and barrel (not include recycle or reclaimed material). All the spare parts are made by ourselves, so we can control the quality and cost totally.

Q: How to install the machine and use the machine?

A: We can send engineer to your factory for worker training and machine installation.

Q: l want make a plastic product,but l don’t know how to choose a suitable machine model,what should I do?

A: Please feel free to tell us about the product detail information, such as size weight,how many output you prefer per hour. We will help make good proposal with nice price for you.

SPECIFICATION

| DESCRIPTION | unit | Phoenix 120PE | Phoenix 170PE | Phoenix 1230PE | Phoenix270PE | Phoenix 320PE | ||||||||||

| International size rating | cm³ | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C |

| INJECTION UNIT | UNIT | |||||||||||||||

| Screw Diameter | mm | 22 | 28 | 35 | 38 | 42 | 45 | 42 | 45 | 50 | 50 | 55 | 60 | 55 | 60 | 65 |

| Screw L:D Ratio | L/D | 22 | 22 | 22 | 22.1 | 20 | 18.7 | 23.6 | 22 | 19.8 | 25.2 | 22.9 | 21 | 22.9 | 21 | 19.4 |

| Shot Volume | cm³ | 64 | 104 | 163 | 226 | 27 7 | 318 | 311 | 357 | 441 | 530 | 641 | 763 | 677 | 805 | 945 |

| Injection Weight(PS) | g | 59 | 95 | 148 | 206 | 252 | 289 | 283 | 325 | 401 | 482 | 583 | 694 | 616 | 733 | 860 |

| njection Rate | cm³/s | 72 | 89 | 134 | 173 | 209 | 239 | 223 | 254 | 312 | 262 | 340 | 405 | 298 | 354 | 406 |

| Injection pressure | MPa | 385 | 342 | 226 | 230 | 200 | 161 | 233 | 198 | 160 | 230 | 200 | 160 | 232 | 195 | 165 |

| Max.Screw Speed | rpm | 400 | 400 | 400 | 350 | 350 | ||||||||||

| CLAMPING UNIT | ||||||||||||||||

| Clamping force | KN | 1200 | 1700 | 2300 | 2700 | 3600 | ||||||||||

| Toggle Stroke | mm | 360 | 435 | 475 | 540 | 615 | ||||||||||

| Space Between Tie Bars | mm | 410X410 | 460X460 | 520X520 | 570X570 | 670X650 | ||||||||||

| Maxmold Height | mm | 430 | 520 | 530 | 580 | 680 | ||||||||||

| Min. Mald Height | mm | 160 | 180 | 200 | 200 | 200 | ||||||||||

| Ejector Stroke | mm | 100 | 135 | 140 | 150 | 160 | ||||||||||

| Ejector force | KN | 30 | 50 | 70 | 70 | 100 | ||||||||||

| OTHERS | ||||||||||||||||

| Max.Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | ||||||||||

| Motor Power | KW | 21 | 28 | 36 | 43 | 56 | ||||||||||

| Heater Power | KW | 7.6 | 9.3 | 12.3 | 16.8 | 18.3 | ||||||||||

| Mochine Dimension | m | 4.4X1.2X1.8 | 5.04X1.43X2.12 | 5.68X1.50X2.14 | 5.90X1.60X2.25 | 7.1X1.9X2.34 | ||||||||||

| Oil Tank Capacity | L | 220 | 300 | 300 | 380 | 450 | ||||||||||

| Machine Weight | tom | 3.8 | 6.2 | 7.2 | 8.8 | 11.5 | ||||||||||

TEMPLATE SIZE

Phoenix 170PE

Phoenix 230PE

Phoenix 270PE

Phoenix 320PE

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Best High Quality Multiplas Injection Molding Machine Manufacturers - Phoenix-PE Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Sacramento, Adelaide, Anguilla, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.