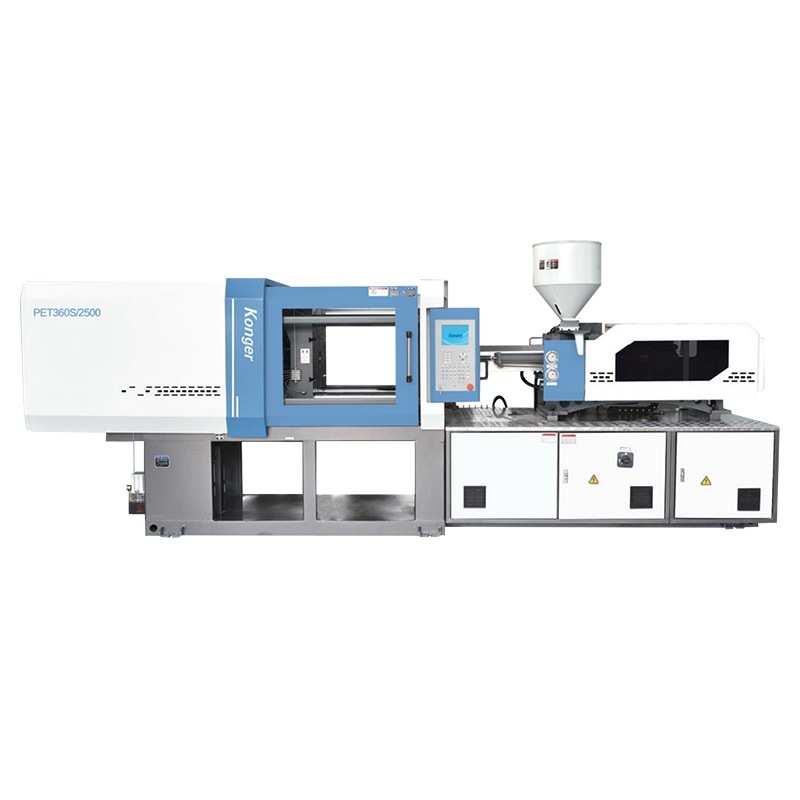

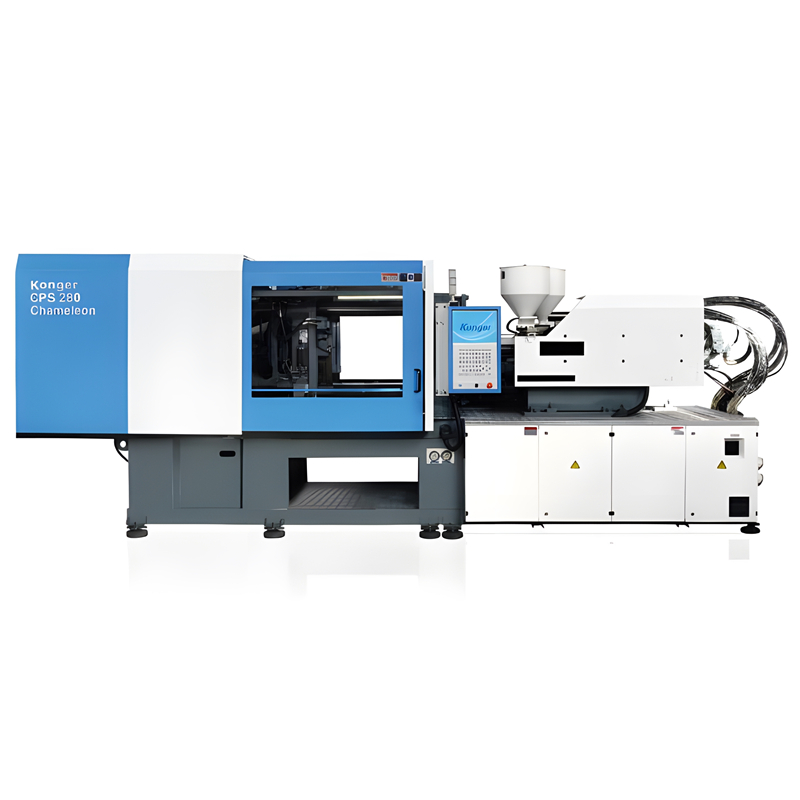

China wholesale Crown Molding Machines Suppliers - Chameleon-CS Series Plastic Injection Molding Machine – KONGER

China wholesale Crown Molding Machines Suppliers - Chameleon-CS Series Plastic Injection Molding Machine – KONGER

China wholesale Crown Molding Machines Suppliers - Chameleon-CS Series Plastic Injection Molding Machine – KONGER Detail:

Product advantages

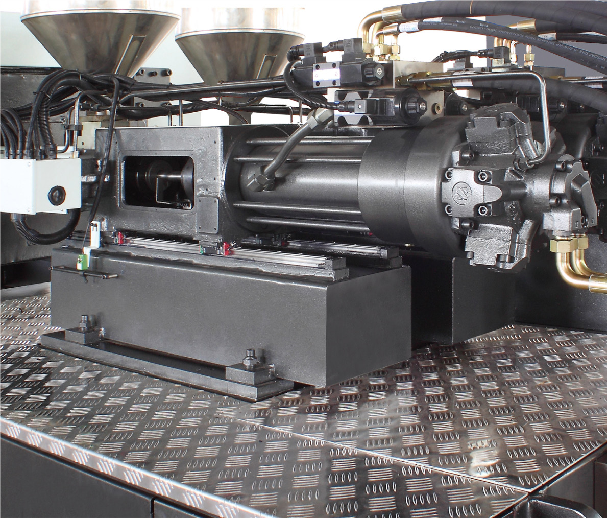

● Efficiently Servo Gear transmission structure keep rotating high speed with stable and precise position.

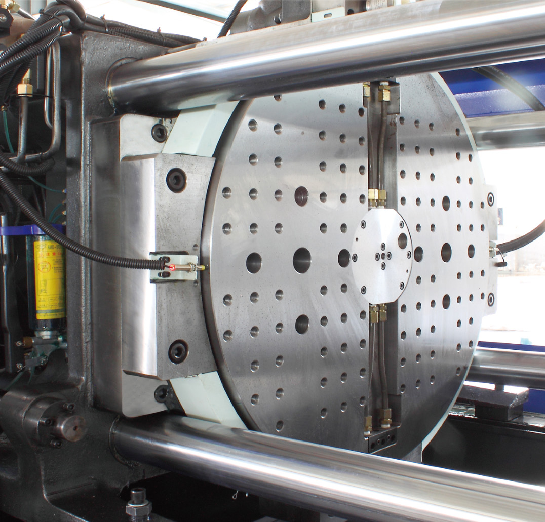

● Graphite copper sleeve used on tie-bar and eject guide bar. Graphite copper block pads used on movement plate and end plate keep the fast and precise moulds open position.

● Reciprocating 180 degree rotation table on movement plate. Can setup two moulds produce the two different color products.

● Single injection cylinder keep injection more stable and precision.

● Low friction drag with precise guide because of injection linear guide.

● Special design all screw L:D=20:1 for all size injection unit setup easy changeable.Can match all customer special requirement.

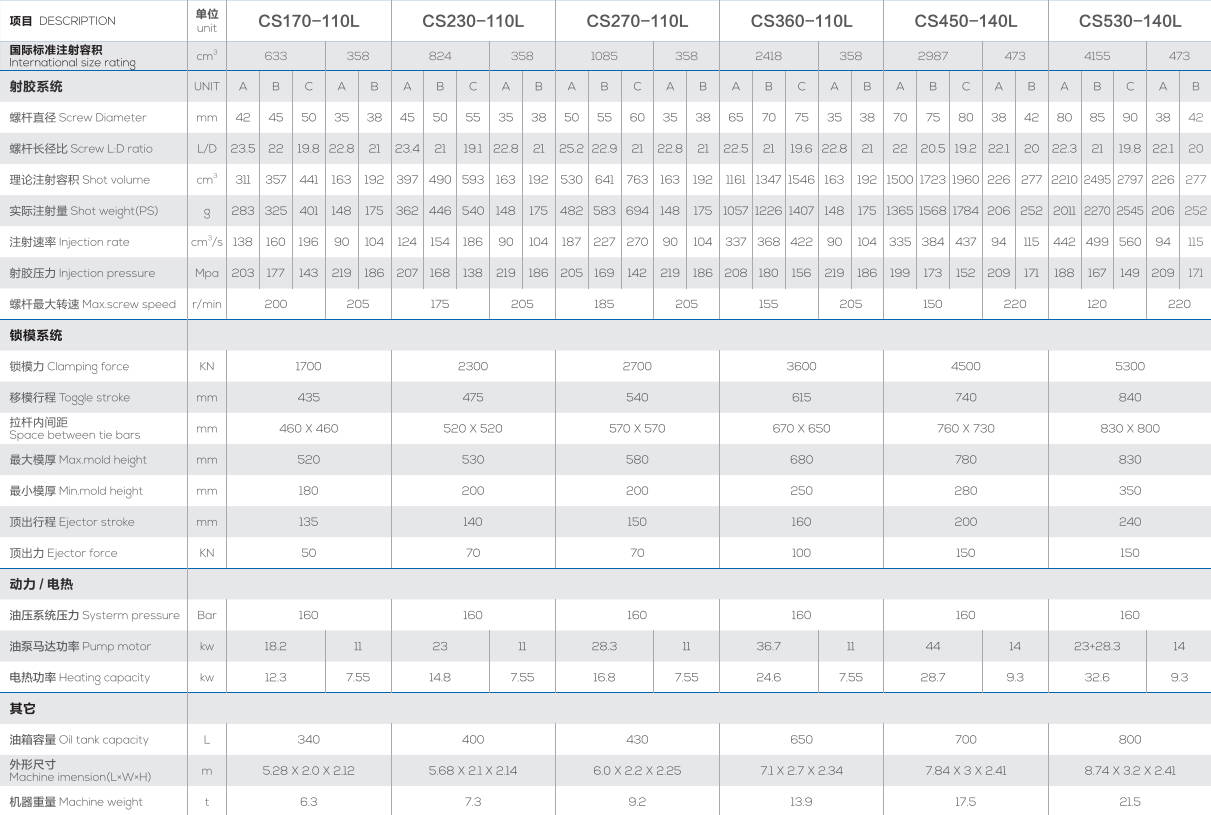

SPECIFICATION

| DESCRIPTION | unit | CPS150 axis | CPS230 axis | ||||||||||||||||||||||

| INJECTION UNIT | A | B | A | B | A | B | A | B | |||||||||||||||||

| Screw Diameter | mm | 28 | 32 | 28 | 32 | 32 | 40 | 32 | 40 | ||||||||||||||||

| Screw LD rotio | L/D | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 20 | 22.5 | 20 | ||||||||||||||||

| Shot volume | cm³ | 108 | 141 | 108 | 141 | 141 | 220 | 141 | 220 | ||||||||||||||||

| Shot welight(PS) | g | 98 | 128 | 98 | 128 | 128 | 200 | 128 | 200 | ||||||||||||||||

| oz | 3.5 | 4.5 | 3.5 | 4.5 | 4.5 | 7.1 | 4.5 | 7.1 | |||||||||||||||||

| Injection pressure | Bar | 2699 | 2066 | 2699 | 2066 | 2640 | 1690 | 2640 | 1690 | ||||||||||||||||

| njection rate | cm³/s | 79 | 83 | 79 | 83 | 83 | 129 | 83 | 129 | ||||||||||||||||

| Plosticizing capooity | g/s | 9 | 10 | 9 | 10 | 12 | 18 | 12 | 18 | ||||||||||||||||

| injection stroke | mm | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | ||||||||||||||||

| Injection speed | mm/s | 120 | 120 | 120 | 120 | 103 | 103 | 103 | 103 | ||||||||||||||||

| Max screw speed | r/min | 221 | 221 | 221 | 221 | 221 | 221 | 221 | 221 | ||||||||||||||||

| CLAMPING UNIT | |||||||||||||||||||||||||

| Clamping force | KM | 1500 | 2300 | ||||||||||||||||||||||

| Opening stroke | mm | 445 | 475 | ||||||||||||||||||||||

| Space between tle bars | mm | 470×470 | 520×520 | ||||||||||||||||||||||

| Mold height (Max-Min) | mm | 180~ 520 | 200~ 530 | ||||||||||||||||||||||

| Ejector stroke | mm | 70 | 80 | ||||||||||||||||||||||

| Ejector stroke | mm | 140 | 140 | ||||||||||||||||||||||

| Number of ejector | Pcs | lX2 | lX2 | ||||||||||||||||||||||

| Distance Berrel Centers | mm | 280 | 300 | ||||||||||||||||||||||

| POWER UNIT | |||||||||||||||||||||||||

| Systerm pressure | Bar | 160 | 160 | ||||||||||||||||||||||

| Pump motor | KW | 14 | 14 | 14 | 14 | ||||||||||||||||||||

| Heating capacity | KW | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | ||||||||||||||||

| Number of temp zones | 2X4 | 2X4 | |||||||||||||||||||||||

| OTHERS | |||||||||||||||||||||||||

| Oil tank capacity | L | 400 | 460 | ||||||||||||||||||||||

| Machine imension(L xWxH) | m | 5.0X1.43X2.1 | 5.68X1.53X 2.14 | ||||||||||||||||||||||

| Machine weight | t | 6 | 7 | ||||||||||||||||||||||

| Hopper capacity | kg | 25 | 25 | 25 | 25 | ||||||||||||||||||||

| DESCRIPTION | unit | CPS170 | CPS280 | CPS320 | CPS400 | CPS450 | CPS850 | ||||||||||||||||||

| INJECTION UNIT | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | |

| Screw Diameter | mm | 28 | 32 | 28 | 32 | 28 | 32 | 32 | 40 | 32 | 40 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 50 | 50 | 55 |

| Screw LD rotio | L/D | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 20 | 22.5 | 20 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 20 | 20 |

| Shot volume | cm³ | 108 | 141 | 108 | 141 | 108 | 141 | 141 | 219 | 141 | 219 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 442 | 442 | 535 |

| Shot welight(PS) | g | 98 | 128 | 98 | 128 | 98 | 128 | 128 | 199 | 128 | 199 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 402 | 402 | 486 |

| oz | 3.5 | 4.5 | 3.5 | 4.5 | 3.5 | 4.5 | 4.5 | 7 | 4.5 | 7 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 14.2 | 14.2 | 17.2 | |

| Injection pressure | Bar | 2699 | 2066 | 2699 | 2066 | 2699 | 2066 | 2066 | 1322 | 2066 | 1322 | 1960 | 1549 | 1960 | 1549 | 1960 | 1549 | 1960 | 1549 | 1960 | 1549 | 1960 | 1254 | 1638 | 1354 |

| njection rate | cm³/s | 79 | 83 | 79 | 83 | 99 | 121 | 121 | 112 | 131 | 141 | 171 | 216 | 171 | 216 | 171 | 216 | 218 | 274 | 218 | 274 | 218 | 340 | 326 | 394 |

| Plosticizing capooity | g/s | 9 | 10 | 9 | 10 | 11 | 12 | 12 | 18 | 12 | 18 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 27 | 48 | 48 | 59 |

| injection stroke | mm | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 |

| Injection speed | mm/s | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 190 | 190 | 136 | 136 | 136 | 136 | 136 | 136 | 173 | 173 | 173 | 173 | 173 | 173 | 166 | 166 |

| Max screw speed | r/min | 221 | 221 | 221 | 221 | 250 | 250 | 250 | 250 | 280 | 280 | 250 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| CLAMPING UNIT | |||||||||||||||||||||||||

| Clamping force | KM | 1700 | 2800 | 3200 | 4000 | 4500 | 8500 | ||||||||||||||||||

| Opening stroke | mm | 445 | 460 | 460 | 600 | 600 | 1000 | ||||||||||||||||||

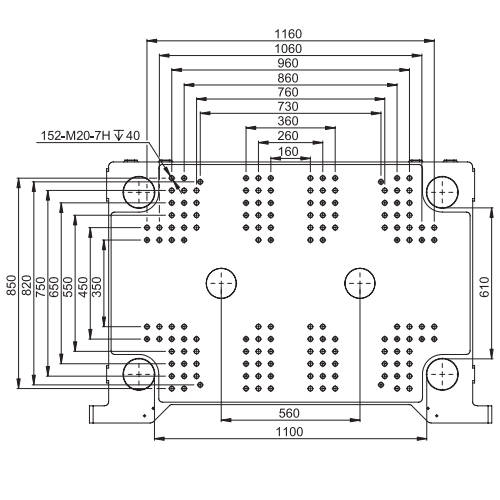

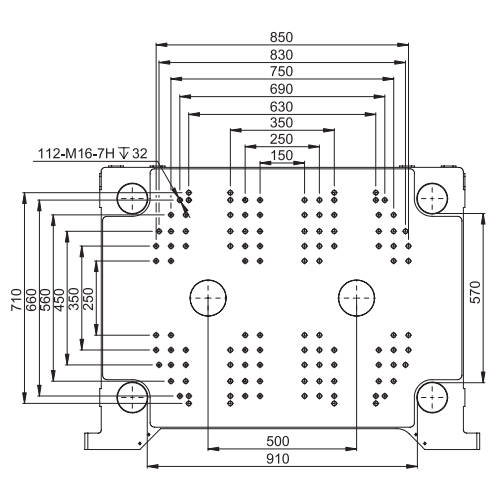

| Space between tle bars | mm | 700 X 440 | 910 X 570 | 910 X 570 | 1100X610 | 1100X610 | 1060X1010 | ||||||||||||||||||

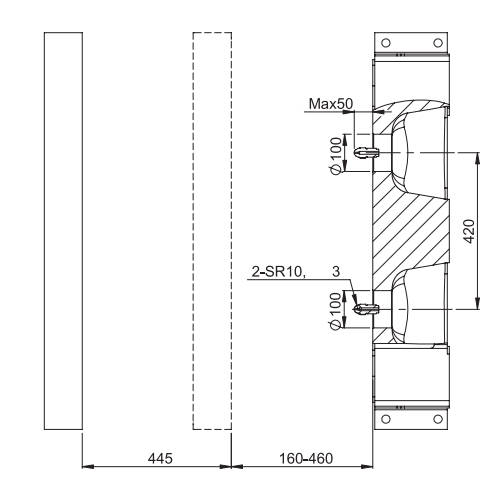

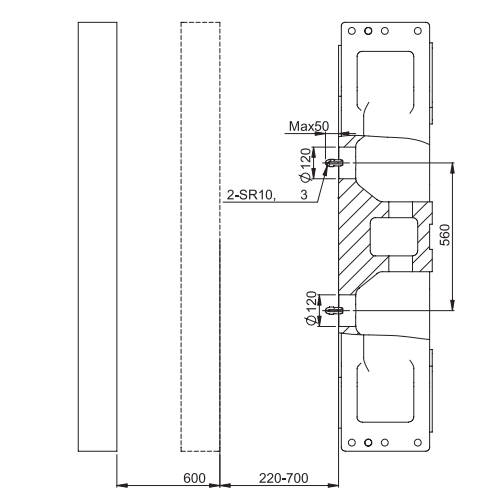

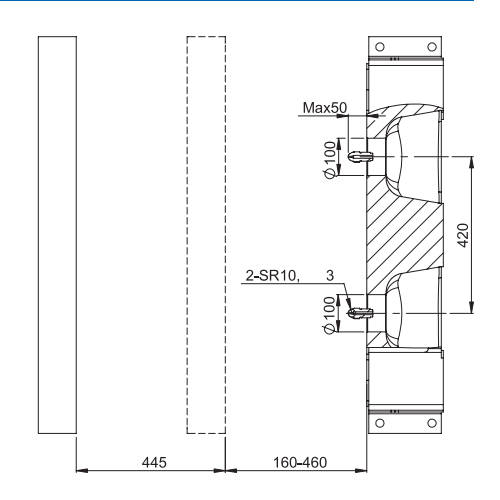

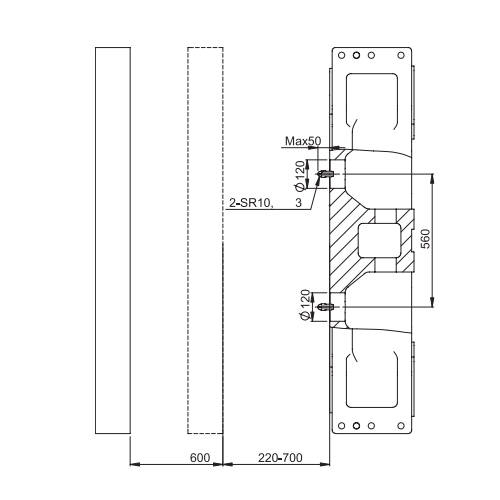

| Die Height(Min-Max) | mm | 160~ 460 | 200~ 510 | 200~ 510 | 220~ 700 | 220~ 700 | 500~ 1050 | ||||||||||||||||||

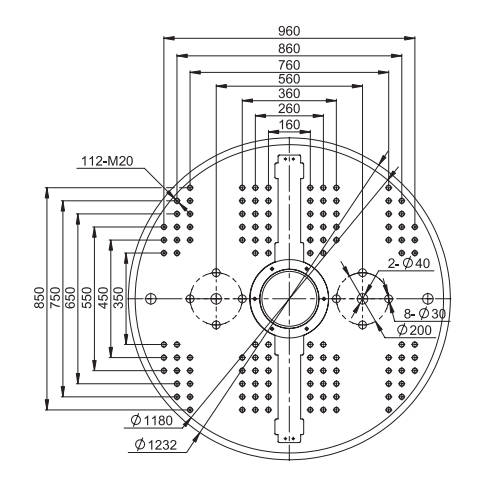

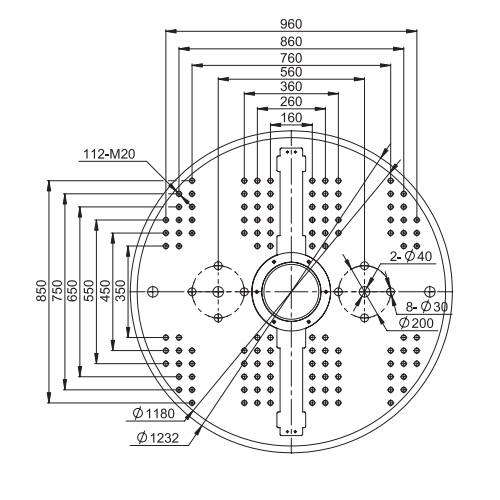

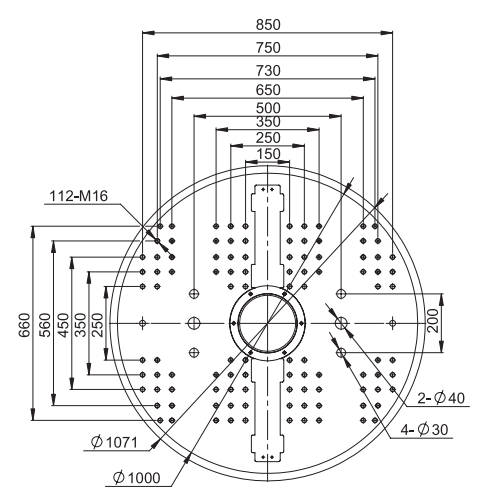

| Rotary Table Diameter | mm | 800 | 1000 | 1020 | 1150 | 1180 | 1530 | ||||||||||||||||||

| Ejector stroke | mm | 100 | 140 | 140 | 140 | 140 | 130 | ||||||||||||||||||

| Ejector force | Pcs | 38X2 | 53X2 | 53X2 | 70X2 | 70X2 | 70X2 | ||||||||||||||||||

| Number of ejector | mm | 3X2 | 3X2 | 3X2 | 5X2 | 5X2 | 5X2 | ||||||||||||||||||

| Distance Berrel Centers | 420 | 500 | 500 | 560 | 560 | 650 | |||||||||||||||||||

| POWER UNIT | |||||||||||||||||||||||||

| Systerm pressure | Bar | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||||||||||

| Pump motor | KW | 14 | 14 | 18.2 | 18.2 | 23 | 23 | 23 | 23 | 28.3 | 28.3 | 28.3 | 36.7 | ||||||||||||

| Heating capacity | KW | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 12.3 | 12.3 | 6.8 | 6.8 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 17.3 | 17.3 |

| Number of temp zones | 2X4 | 2X4 | 2X4 | 2X4 | 2X4 | 2X5 | |||||||||||||||||||

| OTHERS | |||||||||||||||||||||||||

| Oil tank capacity | L | 400 | 460 | 500 | 650 | 700 | 1100 | ||||||||||||||||||

| Machine imension(L xWxH) | m | 5.0X1.76X 2.1 | 5.0X1.76X 2.1 | 6.1X2.1X2.2 | 6.8X2.37X2.3 | 7.0X2.0X2.0 | 11.2X3.05X2.75 | ||||||||||||||||||

| Machine weight | t | 7.1 | 12 | 12.5 | 20 | 20.5 | 48 | ||||||||||||||||||

| Hopper capacity | kg | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | ||||||||||||

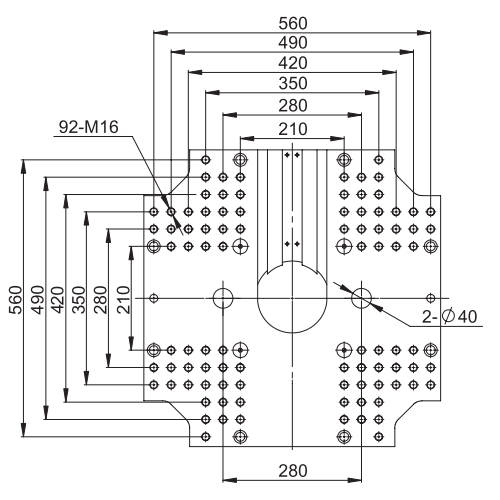

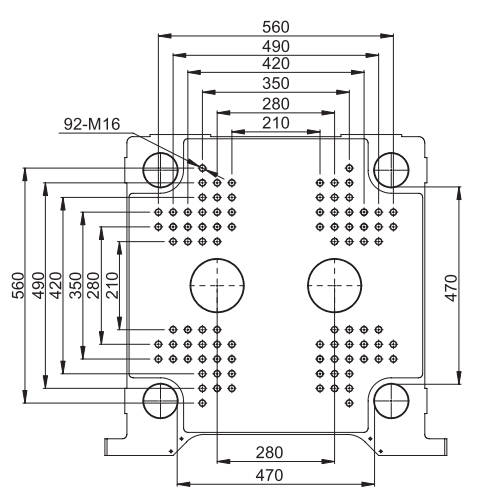

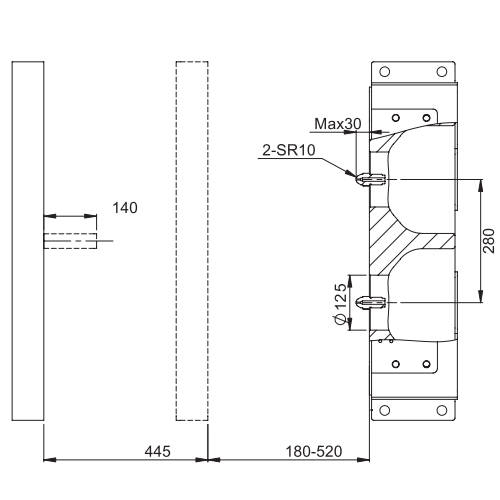

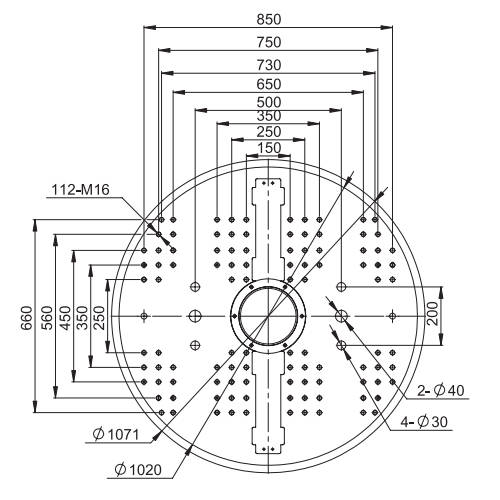

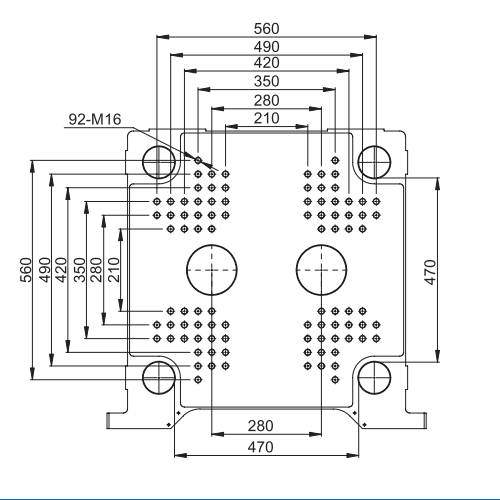

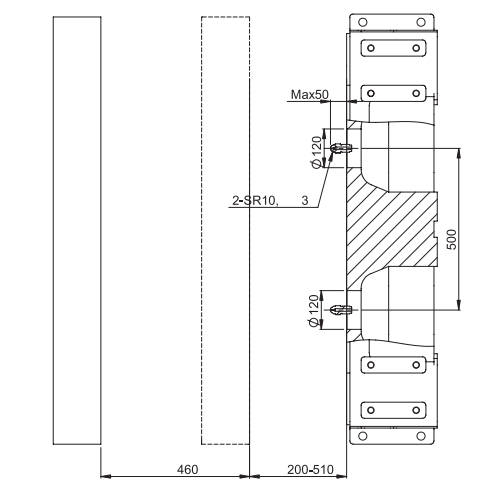

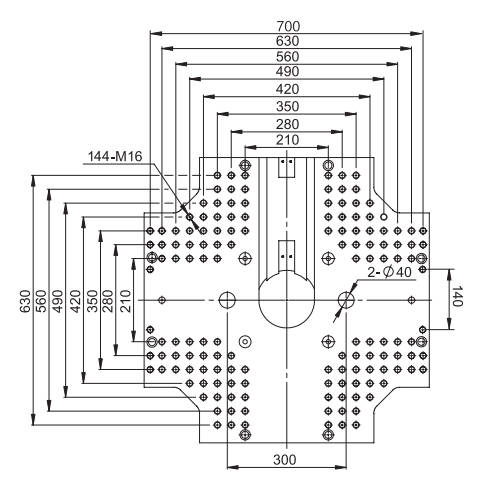

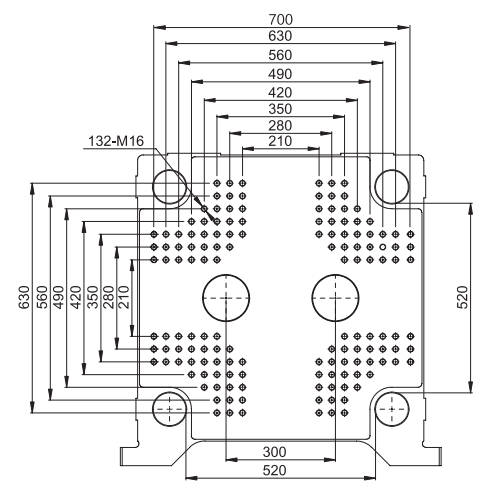

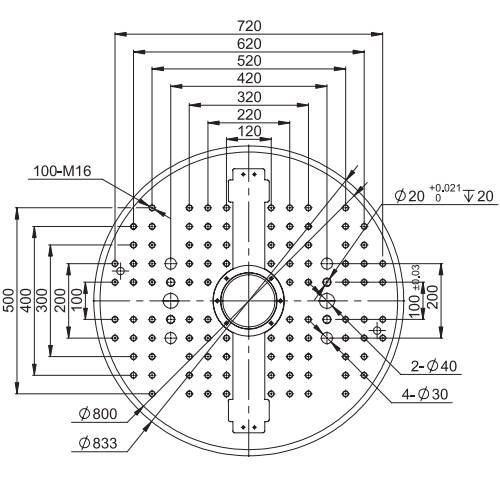

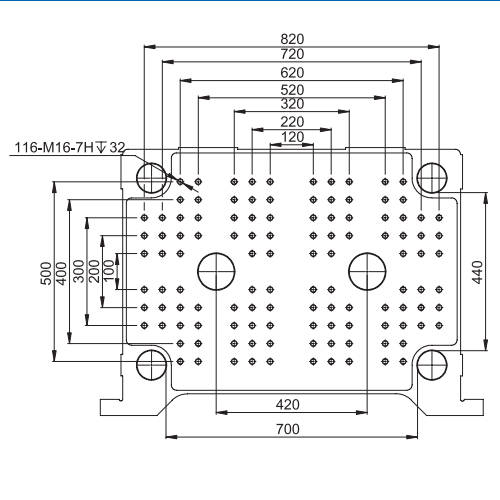

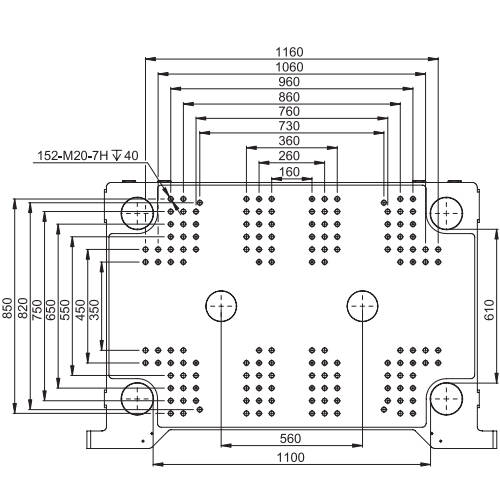

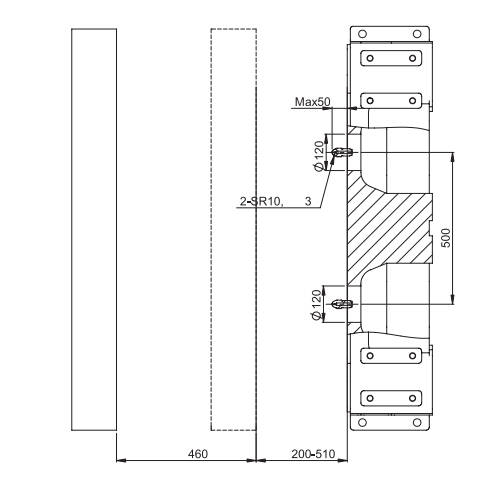

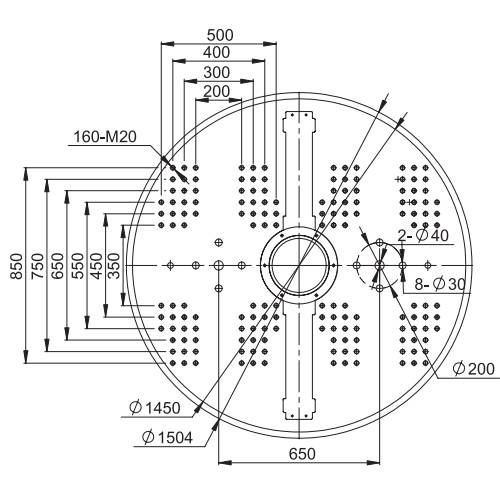

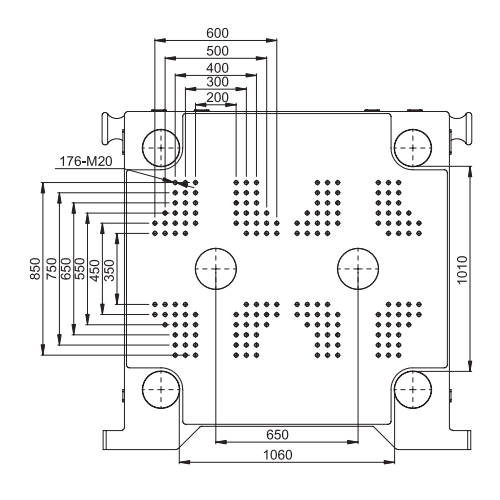

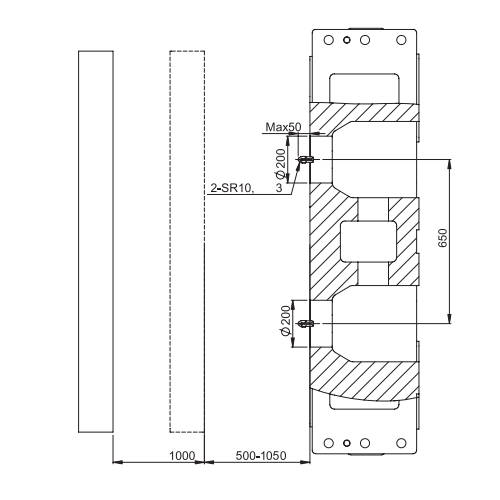

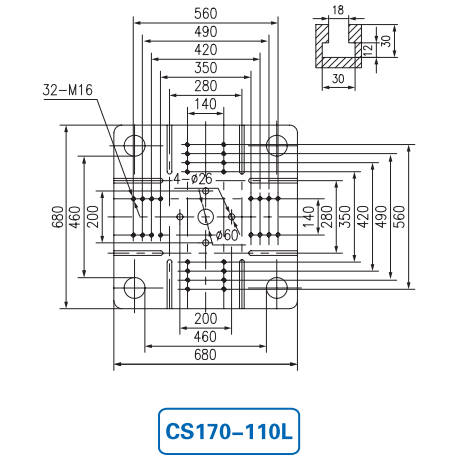

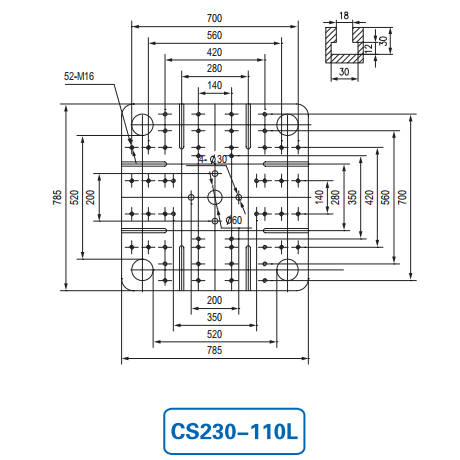

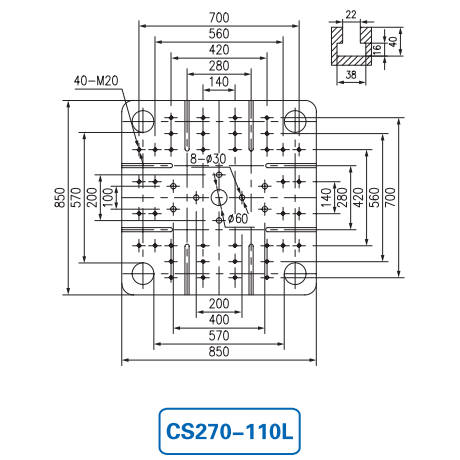

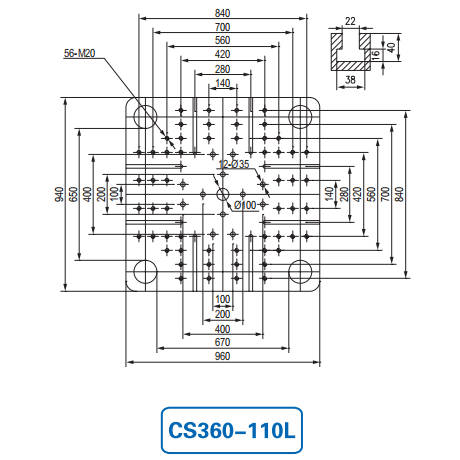

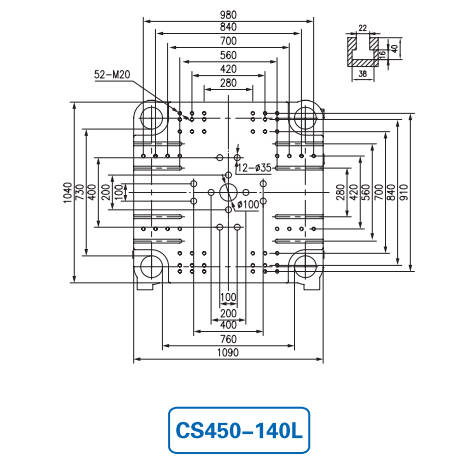

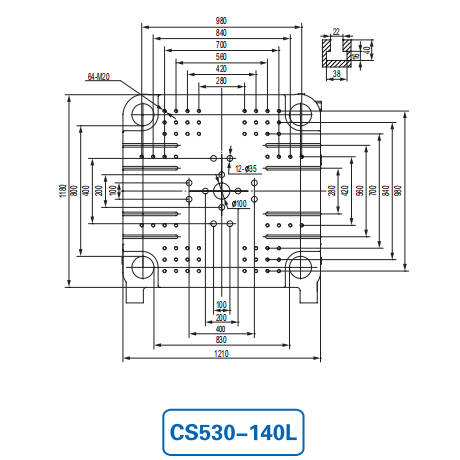

Template plane diagram

L model clean two color

● The two injection unit be L design for clean two color.

● Reciprocating 180 degree rotation table on movement plate.Can setup one moulds produce the two different color products.

●Efficiently servo gear transmission structure keep rotating high speed with stable and precise position.

● Multi-plate design can suit for all products requirement rotation table or rotation shaft.

● Without touch the clamp when the turntable running. Can reduce fault because of the abrasion. Precise position before moulds closed keep the moulds safety.

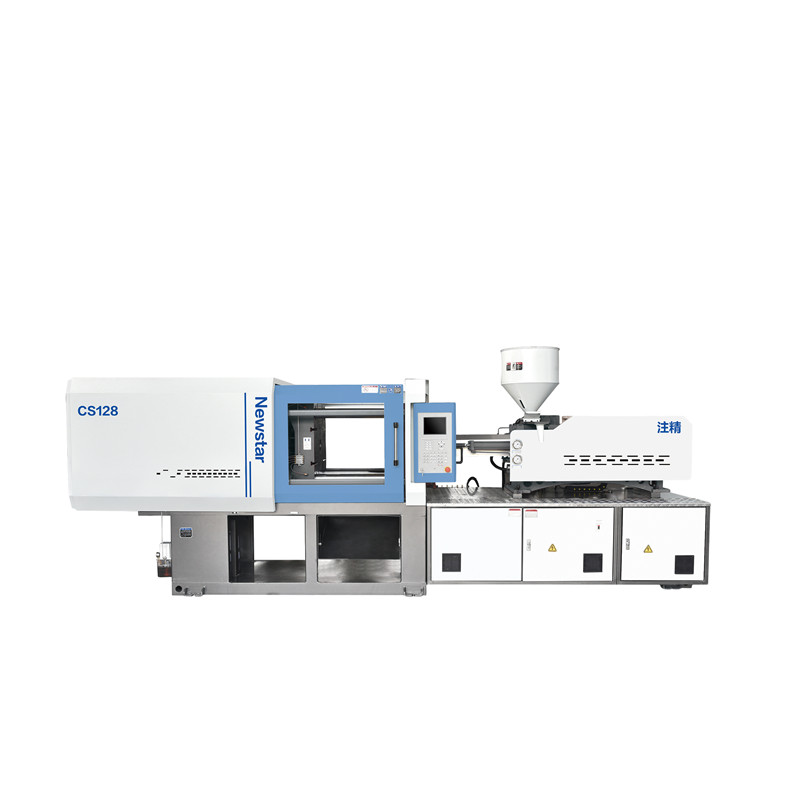

CS230-IIOL

Template size

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of quality first, buyer supreme for China wholesale Crown Molding Machines Suppliers - Chameleon-CS Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: America, Romania, Paris, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.