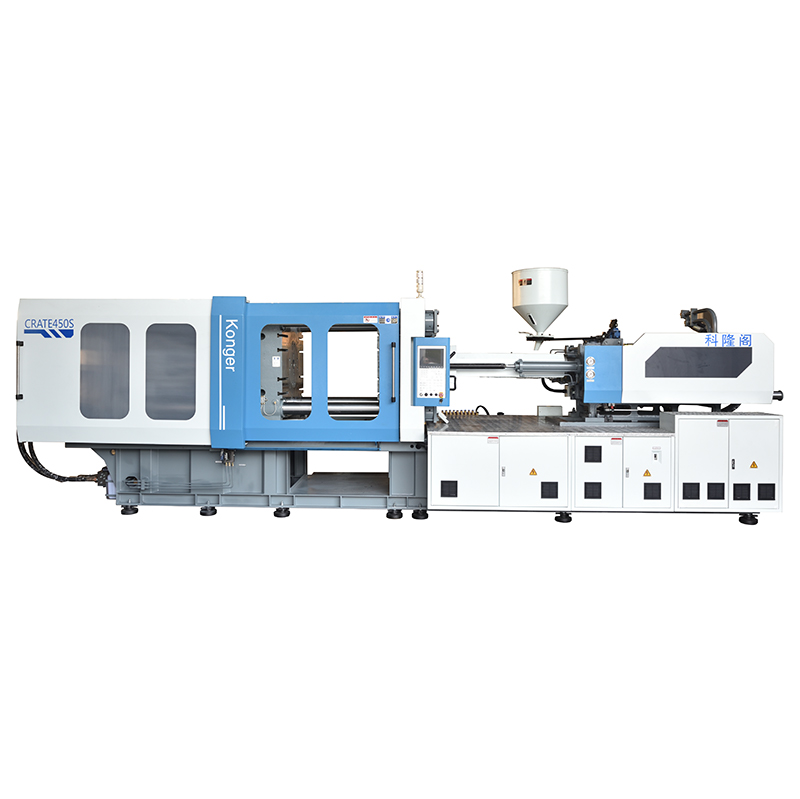

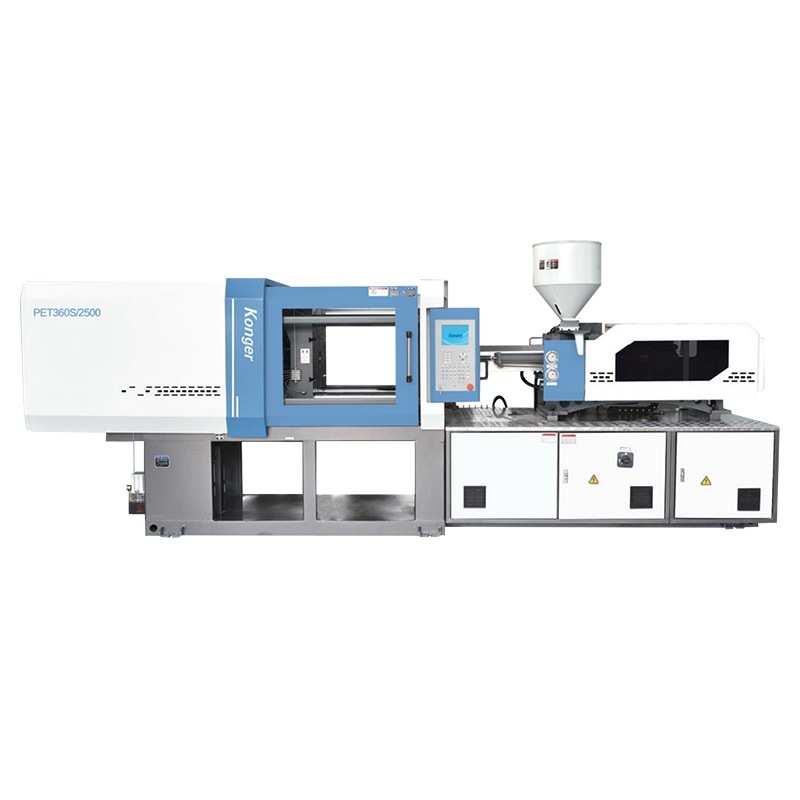

China wholesale Moulding Equipment Factories - PET Series Plastic Injection Molding Machine – KONGER

China wholesale Moulding Equipment Factories - PET Series Plastic Injection Molding Machine – KONGER

China wholesale Moulding Equipment Factories - PET Series Plastic Injection Molding Machine – KONGER Detail:

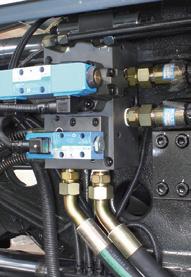

Features

Fully cover of the clamping unit. Conforming to health and temperature control exactly.

Special function for PIN-VALVE button.

Increase production capacity 15%-25% under the synchronized holding presSure system.

Providing the complete solutions of PET-IMM technology &machines, such as: injection machines, blowing machines, moulds, and the other auxiliaries, ect.

SPECIFICATION

| DESCRIPTION | UNIT | PET 1705/ 418 |

PET 170S/ 530 |

PET 230S/ 1000 |

PET 2705/ 1000 |

PET 2705/ 1500 |

PET 3105/ 1500 |

PET 360S/ 1800 |

PET 360S/ 2500 |

PET 4505/ 2500 |

PET S30S/ 3600 |

PET 8005/ 4600 |

| INJECTION UNIT | ||||||||||||

| Screw Diameter | mm | 45 | 50 | 62 | 62 | 72 | 72 | 75 | 82 | 82 | 95 | 105 |

| Screw L/D Ratio | ||||||||||||

| Shot Volume | cm³ | 357 | 450 | 860 | 860 | 1300 | 1300 | 1540 | 2150 | 2150 | 3100 | 3960 |

| PET(1.17) Shot Weight(Ps) | g | 418 | 527 | 1006 | 1006 | 1521 | 1521 | 1802 | 2516 | 2516 | 3627 | 4633 |

| Injection Rate | g/s | 160 | 196 | 270 | 295 | 312 | 312 | 357 | 437 | 557 | 612 | 781 |

| Injection Pressure | mpa | 177 | 143 | 142 | 142 | 143 | 143 | 140 | 145 | 145 | 149 | 147 |

| Screw Speed | rpm | 180 | 180 | 165 | 185 | 170 | 170 | 155 | 155 | 165 | 150 | 135 |

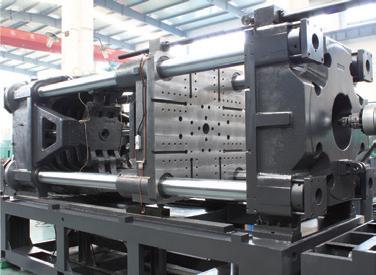

| CLAMPING UNIT | ||||||||||||

| Clamping Force | kn | 1700 | 1700 | 2300 | 2700 | 2700 | 3100 | 3600 | 3600 | 4500 | 5300 | 8000 |

| Toggle Stroke | mm | 435 | 435 | 475 | 540 | 540 | 590 | 615 | 615 | 740 | 840 | 1000 |

| Space Between Tie-Bars (WxH ) | mm*mm | 460 X 460 | 460 X 460 | 520 X 520 | 570 X 570 | 570 X 570 | 615 X 615 | 670 X 650 | 670 X 650 | 760 X 730 | 830 X 800 | 1020 X 970 |

| Mold Height (Min~Max) | mm | 180~500 | 180~500 | 200~530 | 200~550 | 200~550 | 220~600 | 250~680 | 250~ 680 | 280~ 750 | 350~ 830 | 400~ 960 |

| Ejector Stroke | mm | 135 | 135 | 140 | 150 | 150 | 150 | 160 | 160 | 200 | 240 | 300 |

| Ejector Tonnage | kn | 50 | 50 | 70 | 70 | 70 | 100 | 150 | 150 | 150 | 150 | 210 |

| OTHERS | ||||||||||||

| Max.Pump Pressure | mpa | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Motor Power | kw | 28 | 28 | 36 | 43 | 56 | 56 | 56 | 65 | 43+43 | 56+56 | 65+65 |

| Heater Power | mpa | 17.3 | 17.3 | 22 | 22 | 25.8 | 25.8 | 25.8 | 36.6 | 36.6 | 45.2 | 75.6 |

| Machine Dimension | m*m*m | 5.5×1.40 x2.1 |

5.5×1.40 x2.1 |

6.14xl.50 x2.14 |

6.34×1.60 x2.25 |

7.21xl.66 x2.37 |

7.21×1.66 x2.37 |

7.54×1.86 x2.41 |

7.54×1.86 x2.41 |

8.24×1.88 x2.41 |

10.2×2.05 x2.37 |

13.9×2.4 x3.1 |

| Oil Tank Capacity | l | 300 | 300 | 300 | 380 | 380 | 385 | 620 | 620 | 700 | 800 | 1200 |

| Machine Weight | t | 6.5 | 6.5 | 7.5 | 8.5 | 9 | 9.5 | 13 | 13 | 16 | 22 | 37 |

TEMPLATE SIZE

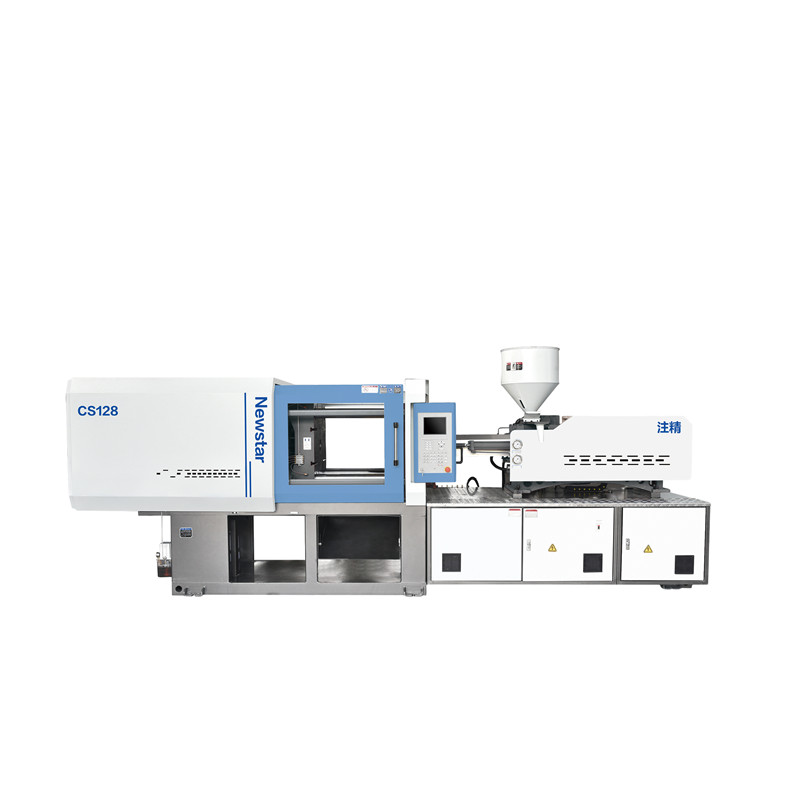

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science and the theory of quality the basic, belief the very first and management the advanced for China wholesale Moulding Equipment Factories - PET Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Myanmar, Austria, Lyon, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Write your message here and send it to us