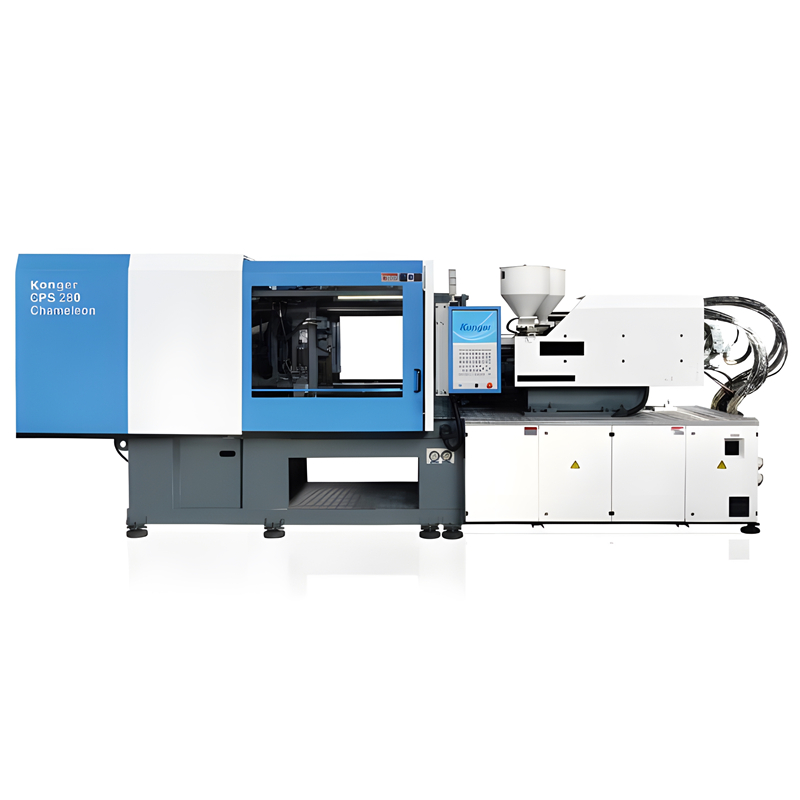

China wholesale Niigon Machines Ltd Manufacturers - Crate-Servo Motor Series Plastic Injection Molding Machine – KONGER

China wholesale Niigon Machines Ltd Manufacturers - Crate-Servo Motor Series Plastic Injection Molding Machine – KONGER

China wholesale Niigon Machines Ltd Manufacturers - Crate-Servo Motor Series Plastic Injection Molding Machine – KONGER Detail:

Product advantages

Electronic Control Unit

Konger uses the controller with imported high-end professional injection moulding machines, it has a clourful display with a large size and make us comfortably. Besides, Konger uses key electronic componets with the famous brand,such as: Schneider, Omron, Siemens,etc. They has more stable quality and reliable function,its benifit to guarantee normally working of the electronic control unit.

Struction Unit

Innovative designed the high stiffness plate with thicken, the frame with high rigidity materials, the structure with enlarge connected and double-injection in the oblique line, which can make sure the frame’s balance and stability, ensure the usefullife of machines will be longer even if it is running with overload operation.

Injection Unit

Specialised to develop the high strength & special alloy screw, ensure the useful life of machines will be longer. Equiping the double hallway pre-injection motor of the leading technology, can make sure the screw feeds more and faster by the enlarge torque, so that mre improving the plasticing capacity. Adopting the most suitable plan,such as enlagre oil passages and the hole of feeding machines, make sure the stability and speed when its running with the sheet stock, crushing or nozzle materials.

SPECIFICATION

| SPECIFICATION | CM | Crate310S | Crate360S | Crate450S | Crate450S/PLUS | Crate500S | Crate500S/PLUS | Crate530S | Crate530S/PLUS | Crate650S |

| INJECTION UNIT | ||||||||||

| Screw diameter | mm | 65 | 75 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Screw ratio | L/D | 20:1 | 20:1 | 21:1 | 21:1 | 21:1 | 21:1 | 19:1 | 19:1 | 20:1 |

| Shot volume | cm² | 945 | 1546 | 2481 | 2481 | 2481 | 2481 | 3450 | 3450 | 3890 |

| Shot weightlPS) | g | 860 | 1407 | 2258 | 2258 | 2258 | 2258 | 3140 | 3140 | 3540 |

| Injection rate | g/s | 352 | 421 | 686 | 824 | 686 | 842 | 897 | 985 | 1093 |

| Injection pressure | MPa | 150 | 156.4 | 120.4 | 120.4 | 120.4 | 120.4 | 120.6 | 120.4 | 120.8 |

| Max.Screw speed | rpm | 0~220 | 0~190 | 0 ~193 | 0 ~230 | 0~193 | 0~230 | 0~150 | 0~160 | 0~165 |

| CLAMPING UNIT | ||||||||||

| Clamping force | KN | 3100 | 3600 | 4500 | 4500 | 5000 | 5000 | 5300 | 5300 | 6500 |

| Toggle Stroke | mm | 590 | 660 | 745 | 745 | 845 | 845 | 845 | 845 | 900 |

| Space Between Tie- Bars( WxH ) | mm | 615X6I5 | 660X660 | 760X730 | 760X730 | 830X800 | 830X800 | 830X800 | 830X800 | 925X875 |

| Mold Height ( Min-Max ) | mm | 200~ 630 | 250~ 680 | 280~ 780 | 280~ 780 | 350~ 830 | 350~ 830 | 350~ 830 | 350~ 830 | 350~ 900 |

| Ejector Stroke | mm | 150 | 160 | 200 | 200 | 240 | 240 | 240 | 240 | 285 |

| Ejector Tonnage | KN | 90 | 100 | 110 | 110 | 150 | 150 | 150 | 150 | 150 |

| PCS | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | |

| OTHERS | ||||||||||

| Max, Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Motor Power | KW | 56 | 65 | 65+14 | 65+36 | 65+14 | 65+36 | 65+43 | 65+36 | 65+36 |

| Heating capacity | KW | 18.3 | 24.6 | 31.6 | 31.6 | 31.6 | 31.6 | 46 | 46 | 51 |

| Machine Dimension | m | 5.98X1.66X2.37 | 7.21X19X2.34 | 7.54X1.88X2.41 | 7.54X1.88X2.41 | 8.75X2.16X2.92 | 8.75X2.16X2.92 | 8.95X2.16X2.92 | 8.95X2.16X2.92 | 10.2X2.24X2.71 |

| Oil Tank Capacity | L | 600 | 620 | 830 | 830 | 890 | 890 | 900 | 900 | 1100 |

| Machine Weight | T | 115 | 125 | 15.2 | 15.4 | 19.2 | 19.5 | 19.8 | 20 | 28 |

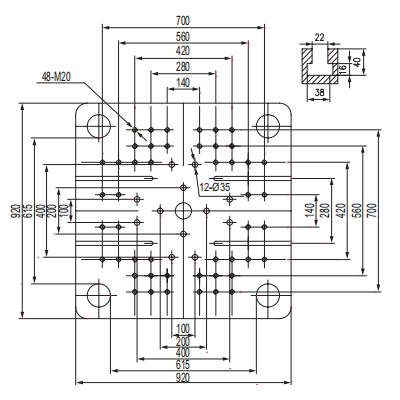

TEMPLATE SIZE

Crate360S

Crate450S

Crate450S/PLUS

Crate500S

Crate500S/PLUS

Crate530S

Crate530S/PLUS

Crate650S

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for China wholesale Niigon Machines Ltd Manufacturers - Crate-Servo Motor Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: kazakhstan, Armenia, Ukraine, Our company will adhere to Quality first, , perfection forever, people-oriented , technology innovationbusiness philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.