China wholesale Pet Injection Moulding Machine Suppliers - K-TEC Series Plastic Injection Molding Machine – KONGER

China wholesale Pet Injection Moulding Machine Suppliers - K-TEC Series Plastic Injection Molding Machine – KONGER

China wholesale Pet Injection Moulding Machine Suppliers - K-TEC Series Plastic Injection Molding Machine – KONGER Detail:

K-TEC series

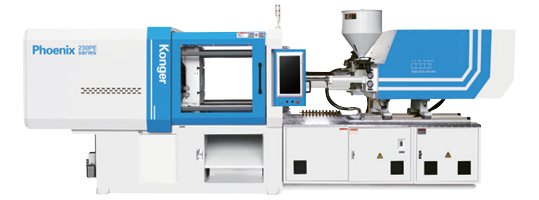

PHOENIX series

Dry series

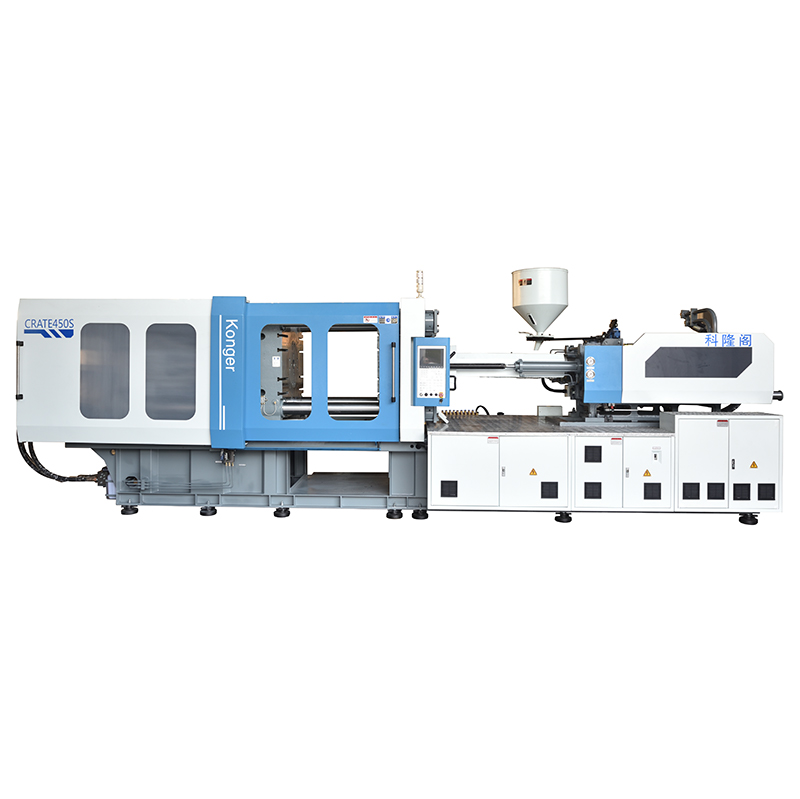

Crate series

Bakelite series

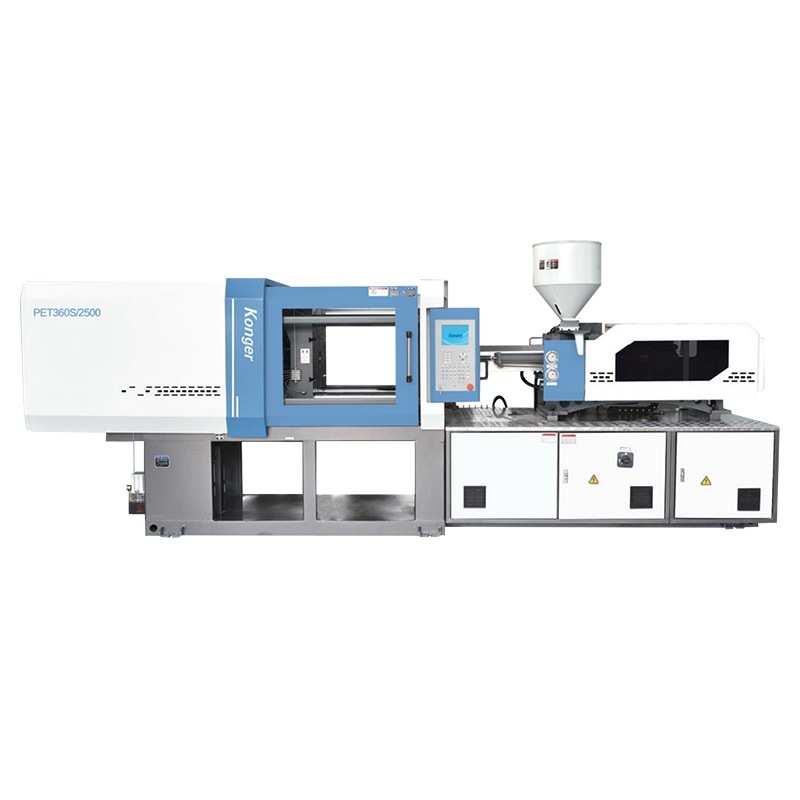

PET series

Chameleon series

Product advantages

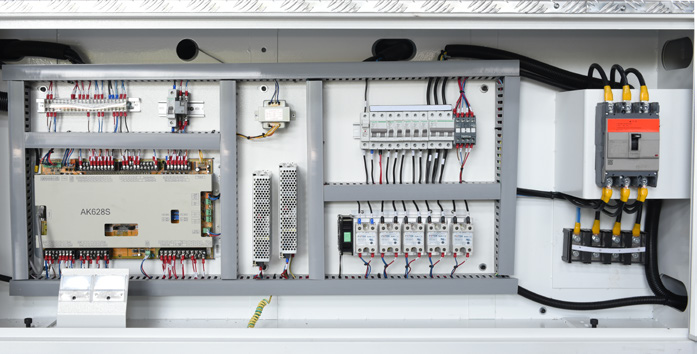

● World Famous Brands Electric Parts Stable operation

● High-Performance Injection Unit Double cylinder injection system, high injection efficiency maximize control of the precison

Product Description

● Tie bar adopt surface hard chromium plating processing.

● With adjustable fect slip block structure.

● Automated centrauzed lubrication system.

● Sgnchronous gear mold adjustment.

● Sensor feet connecting thrust block.

● Optimization design of toggle Structure,clamp of opening and

closing fast and smooth.

● Double guide bars, improve inject technology.

● High speed hydraulic motor for screw.

● Screw barrel demolishing vertically makes it easy to replace.

● Injection, holding pressure closed-loop control and precise back

pressure control.

● High-strength mechanical structure design, keep lasting precision.

● Low speed and high torque hydraulic motor drive screw rotation,

excellent performance of plastic.

● Optimized design of screw, wide range of raw materials.

● Adopting Taiwan’s technology to produce valve

● Hydraulic circuit designed to meet international safety standards

● No welding pipe in order to achieve stable and reliable maintain

● Automatically read oil temperature

● Adopt international well-know hydraulic components

● Support for multiple languages.

● System with dual-core microprocessors makes it high-speed, anti-noise, low power consumption.

● USB interface can be updated or backup system

parameters.

● Internal inspection Ethernet interface, convenient

connection.

● Smart security features like page prompts, Provide

maintenance tips and warranty.

● Injection pressure, velocity, end and holding pressure curve

display graphical.

● With a record 120 groups and 120 groups to modify alarm

recording function.

● Computer boot self-test function and mechanical failure

alarm.

● I / O simulation capabilities that enable online analog input

and output points.

● Supports simultaneous monitoring of multiple machines

through an office computer, corporate managers may.

differ according to the production process, production

resources planning.

● User-friendly design layout manipulation.

● Servo drives can achieve a variety of control methods of

digital control and analog control.

● Multiple closed-loop monitoring device as standard

transfer mode electric eye, the analyte electric eye, speed

electric eye, etc.

Excellent molding produce valvestability

The servo driving system has its pressure and flow under close loop control; and compared with traditional injection molders, its molding repetition precision is improved substantially.

Rapid response

The servo driver features rapid response whose rapid starting time is improved by 50% compared with traditional injection.

High performanceV environmental protection

The complete machine features. Iow operating noise, and even quieter during Iow speed operation.

Constant oil temperature

The serve motor output hydraulic oil proportionately to prevent excessive heat. It can achieve substantial water saving even without cooling.

Substantial energy saving

Under the same conditions, it can save 20%-80% energy compared with traditional constant delivery pump injection molders.

● Supply the bst solutions with technolog support for customer

● Get more details requirement from customer

● Chose the best option for customer.

● Help the customer choose best machins size

● Help the customer give the solutions for auxiliery machines.

● Helo the customer design the electrial/air/water ect at 、

customer factory.

● Give the best special solutions fror customer.

● Delivery the good quality machines on times to customer. And

training customer engineer and workers.

● Delivery on times.

● Setup machines and adjustment free charge.

● Training the engineer and workers free charge.

● All the KONGER machines we will give the service at machines

whole life.

● Prepared the parts for all customer.

100-270ton Consumer Electronics injection molding machine

SPECIFICATION

| SPECIFICATION | CN | K-TEC100 | K-TEC120 | K-TEC140 | K-TEC170 | K-TEC230 | K-TEC270 | ||||||||||||

| VB | cm³ | 358 | 450 | 473 | 633 | 824 | 1085 | ||||||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 35 | 38 | 42 | 35 | 38 | 42 | 38 | 42 | 45 | 42 | 45 | 50 | 45 | 50 | 55 | 50 | 55 | 60 |

| Screw L/D Ratio | L/D | 22.8 | 21 | 19 | 22.8 | 21 | 19 | 22.1 | 20 | 18.7 | 23.5 | 22 | 19.8 | 23.4 | 21 | 19.1 | 25.2 | 22.9 | 21 |

| Shot Volume | cm³ | 163 | 192 | 235 | 163 | 192 | 235 | 226 | 277 | 318 | 311 | 357 | 441 | 397 | 490 | 593 | 530 | 641 | 763 |

| Injection Weight(PS) | g | 148 | 175 | 213 | 148 | 175 | 214 | 206 | 252 | 289 | 283 | 325 | 401 | 362 | 446 | 540 | 482 | 583 | 694 |

| njection Rate | cm³/s | 90 | 104 | 128 | 92 | 108 | 130 | 94 | 115 | 132 | 138 | 160 | 196 | 124 | 154 | 186 | 187 | 227 | 270 |

| njection Pressure | MPa | 219 | 186 | 158 | 219 | 186 | 158 | 209 | 171 | 149 | 203 | 177 | 143 | 207 | 168 | 138 | 205 | 169 | 142 |

| Screw Speed | rpm | 205 | 220 | 220 | 200 | 175 | 185 | ||||||||||||

| Clamping force | KN | 1000 | 1200 | 1400 | 1700 | 2300 | 2700 | ||||||||||||

| Toggle Stroke | mm | 350 | 360 | 380 | 435 | 475 | 540 | ||||||||||||

| Space Between Tie-Bars ( WxH) | mm | 370X370 | 410X410 | 420X420 | 460X460 | 520X520 | 570X570 | ||||||||||||

| Max Mold Height | mm | 380 | 430 | 450 | 520 | 530 | 580 | ||||||||||||

| Min.Mald Height | mm | 150 | 160 | 160 | 180 | 200 | 200 | ||||||||||||

| Ejector Stroke | mm | 100 | 100 | 120 | 135 | 140 | 150 | ||||||||||||

| Ejector Tonnoge | KN | 30 | 30 | 50 | 50 | 70 | 70 | ||||||||||||

| Max.Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| Motor Power | KW | 11 | 14 | 14 | 21 | 28 | 36 | ||||||||||||

| Heater Power | KW | 7.55 | 755 | 9.3 | 12.3 | 148 | 168 | ||||||||||||

| Mochine Dimension | m | 4.2X1.2X1.79 | 4.4×1.2X1.8 | 4.48X1.33X1.90 | 5.18X1.40X2.12 | 5.58X1.50×2.4 | 6.0X1.60X2.25 | ||||||||||||

| OilTank Capacity | L | 190 | 220 | 270 | 300 | 300 | 380 | ||||||||||||

| Machine Weight | tom | 3.5 | 38 | 4.3 | 6 | 7 | 8.5 | ||||||||||||

TEMPLATE SIZE

K-TEC120

K-TEC140

K-TEC170

K-TEC230

K-TEC270

310-500ton Packaging & Medical products injection molding machine

SPECIFICATION

| SPECIFICATION | CN | K-TEC310 | K-TEC320 | K-TEC360 | K-TEC400 | K-TEC450 | K-TEC500 | ||||||||||||

| VB | cma | 1354 | 1354 | 2418 | 2418 | 2987 | 2987 | ||||||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 55 | 60 | 65 | 55 | 60 | 65 | 65 | 70 | 75 | 65 | 70 | 75 | 70 | 75 | 80 | 70 | 75 | 80 |

| Screw L/D Ratio | L/D | 22.9 | 21 | 19.4 | 22.9 | 21 | 19.4 | 22.5 | 21 | 19.6 | 22.6 | 21 | 19.6 | 22 | 20.5 | 19.2 | 22 | 20.5 | 19.2 |

| Shot Volume | cm³ | 677 | 805 | 945 | 677 | 805 | 945 | 1161 | 1347 | 1546 | 1161 | 1347 | 1546 | 1500 | 1723 | 1960 | 1500 | 1723 | 1960 |

| Injection Weight(PS) | g | 616 | 733 | 860 | 616 | 733 | 860 | 1057 | 1226 | 1407 | 1057 | 1226 | 1407 | 1365 | 1568 | 1784 | 1365 | 1568 | 1784 |

| njection Rate | cm³/s | 2235 | 266 | 312.2 | 2235 | 266 | 312.2 | 337 | 368 | 422 | 337 | 368 | 422 | 335 | 384 | 437 | 335 | 384 | 437 |

| njection Pressure | MPa | 200 | 168 | 143 | 200 | 168 | 143 | 208 | 179.6 | 156 | 208 | 179 | 156 | 199 | 173 | 152 | 199 | 173 | 152 |

| Screw Speed | rpm | 185 | 185 | 155 | 155 | 150 | 150 | ||||||||||||

| Clamping force | KN | 3100 | 3200 | 3600 | 4000 | 4500 | 5000 | ||||||||||||

| Toggle Stroke | mm | 590 | 615 | 615 | 740 | 740 | 840 | ||||||||||||

| Space Between Tie-Bars ( WxH) | mm | 615X615 | 670X650 | 670X650 | 760X730 | 760X730 | 830X800 | ||||||||||||

| Max Mold Height | mm | 630 | 680 | 680 | 780 | 780 | 830 | ||||||||||||

| Min. Mald Height | mm | 200 | 250 | 250 | 280 | 280 | 350 | ||||||||||||

| Ejector Stroke | mm | 150 | 160 | 160 | 200 | 200 | 240 | ||||||||||||

| Ejector Tonnoge | KN | 30 | 100 | 100 | 150 | 150 | 150 | ||||||||||||

| Max. Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| Motor Power | KW | 36 | 36 | 43 | 43 | 56 | 56 | ||||||||||||

| Heater Power | KW | 18.3 | 18.3 | 246 | 24.6 | 28.7 | 28.7 | ||||||||||||

| Mochine Dimension | m | 6.2X1.66X2.3 | 7.1X1.84X2.34 | 7.1X1.84X2.34 | 7.54X1.88X2.41 | 7.84X1.92X2.41 | 8.54X2.05X2.3 | ||||||||||||

| OilTank Capacity | L | 380 | 450 | 600 | 650 | 700 | 700 | ||||||||||||

| Machine Weight | tom | 9 | 115 | 12.5 | 15 s | 15.4 | 18 | ||||||||||||

TEMPLATE SIZE

K-TEC320

K-TEC360

K-TEC400

K-TEC450

K-TEC500

530-1400ton Industrial & Civil supplies injection molding machine

SPECIFICATION

| SPECIFICATION | CN | K-TEC530 | K-TEC650 | K-TEC800 | K-TEC1000 | K-TEC1200 | K-TEC1400 | |||||||||||||||||

| VB | cm³ | 4155 | 4680 | 5706 | 6353 | 9792 | 13060 | |||||||||||||||||

| A | B | C | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | ||

| Screw Diameter | mm | 80 | 85 | 90 | 90 | 95 | 100 | 105 | 90 | 95 | 105 | 110 | 90 | 100 | 110 | 115 | 110 | 115 | 120 | 125 | 110 | 120 | 130 | 140 |

| Screw L/D Ratio | L/D | 22.3 | 21 | 19.8 | 20.4 | 19.4 | 18.4 | 175 | 23.2 | 22 | 19.9 | 19 | 25.5 | 23 | 20.9 | 20 | 23 | 22 | 21 | 20.2 | 25.7 | 24 | 22 | 20 |

| Shot Volume | cm³ | 2210 | 2495 | 2797 | 2544 | 2835 | 3141 | 3663 | 2926 | 3260 | 3983 | 4371 | 2920 | 3610 | 4369 | 4778 | 5270 | 5760 | 6272 | 6805 | 627 | 7463 | 8759 | 10158 |

| Injection Weight(PS) | g | 2011 | 2270 | 2545 | 2315 | 2580 | 2858 | 3I51 | 2663 | 2967 | 3624 | 3978 | 2670 | 3300 | 3980 | 4325 | 4796 | 5242 | 5707 | 6193 | 5706 | 6791 | 7970 | 9243 |

| njection Rate | cm³/s | 442 | 499 | 560 | 552 | 612 | 679 | 748 | 574 | 640 | 781 | 858 | 580 | 717 | 867 | 948 | 793 | 867 | 944 | 1024 | 8I5 | 970 | 1138 | 1320 |

| njection Pressure | MPa | 188 | 167 | 149 | 184 | 165 | 149 | 135 | 195 | 175 | 143 | 130 | 216 | 176 | 146 | 133 | 186 | 170 | 156 | 144 | 208 | 175 | 150 | 129 |

| Screw Speed | rpm | 120 | 145 | 125 | 100 | 90 | 90 | |||||||||||||||||

| Clamping force | KN | 5300 | 6500 | 8000 | 100000 | 12000 | 14000 | |||||||||||||||||

| Toggle Stroke | mm | 840 | 900 | 1000 | 1100 | 1250 | 1350 | |||||||||||||||||

| Space Between Tie-Bars ( WxH) | mm | 830X800 | 925X875 | 1020X970 | 1125X1085 | 1180X100 | 1310X1300 | |||||||||||||||||

| Max Mold Height | mm | 830 | 900 | 960 | 1100 | 1250 | 1400 | |||||||||||||||||

| Min.Mald Height | mm | 350 | 350 | 400 | 500 | 500 | 600 | |||||||||||||||||

| Ejector Stroke | mm | 240 | 295 | 300 | 335 | 325 | 360 | |||||||||||||||||

| Ejector Tonnoge | KN | 150 | 150 | 210 | 216 | 245 | 260 | |||||||||||||||||

| Max.Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | |||||||||||||||||

| Motor Power | KW | 28+36 | 43+36 | 43+56 | 43+56 | 56+56 | 43+43+43 | |||||||||||||||||

| Heater Power | KW | 32.6 | 46 | 54.3 | 59 | 661 | 86 | |||||||||||||||||

| Mochine Dimension | m | 8.74X20.5X2.3 | 10.2X2.24X2.71 | 11.8X2.24X2.71 | 12.1X2.64X3 | 12.54X2.66X3.27 | 15.2X3X4.13 | |||||||||||||||||

| OilTank Capacity | L | 800 | 1100 | 1200 | 1400 | 2100 | 2900 | |||||||||||||||||

| Machine Weight | tom | 20 | 28 | 37 | 48 | 55 | 90 | |||||||||||||||||

TEMPLATE SIZE

K-TEC650

K-TEC800

K-TEC1000

K-TEC1200

K-TEC1400

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for China wholesale Pet Injection Moulding Machine Suppliers - K-TEC Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: New York, Oslo, Saudi Arabia, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.