China wholesale Pet Preform Machine Factories - Dry Series Plastic Injection Molding Machine – KONGER

China wholesale Pet Preform Machine Factories - Dry Series Plastic Injection Molding Machine – KONGER

China wholesale Pet Preform Machine Factories - Dry Series Plastic Injection Molding Machine – KONGER Detail:

THE PRODUCT INSTANCE

Indicator Shell

PMMA Materials

Shredder Shell

● Indicator shell, PC customer inventory for many years recycling nozzle material, the original drying material 110 degrees 5-7 hours, can be produced after transformation.

● PMMA materials, originally need 3 h baking material 85 degrees, colour often appear problem, after using desiccant screw, color is consistent, obviously increase 30% concentrated degree, without drying of material production.

● Shredder shell, PC granulation material, the customer purchasing yuyao 2013 hair big bubble had a total of 230 tons of raw materials, cheap, 1000 per ton. There is no need to use 200 kg bake VAT before modification 2 drying of material, modified without drying of material, can be produced.

Nylon Material

PBT Material

South Korea Samsung Group Power Housing

Nylon Fishing Net Granulation Material + 30% Gf

PBT Material

● Nylon material, moisture content of 8%, normal drying material 100 degrees 10-12h, can be produced after transformation, without drying material.

●PBT raw materials, standard machine need to dry material 120-140 degrees 2.5-5h, the use of dehumidifying screw can be produced, without drying material.

● South Korea Samsung Group power housing, PC-V0 granulation material. The original sample has obvious binding line, but the modified product has no binding line.

● fishing net nylon granulation material +30%GF, normal drying material 120 degrees 6-8H, the use of dehumidifying screw without drying material, can be produced.

PA 30%gf Electronic Products

PC Material Stock

Lampshade For Years

POM Raw Gear

PC Lampshade

PMMA

Auto Tail Lampshade

PA + ABS Is Bubble Water Casing Materials Shredding

High Temperature PC Sinotruk

Lampshade

PMMA

Auto Tail Lampshade

Product advantages

Dehumidifying Screw Principle

Use screw high temperature, high pressure in a short time to evaporate the water of plastic raw materials.

This Product Is Adapted To

ABS, PC+ABS, PC, PA, PMMA, POM, PP+GF, PBT, PPS, LCP and other engineering materials.

Dehumidification Screw Motion Analysis

In the feed opening paragraph 1 immediately for high temperature and evaporation, let the moisture in the raw material at high temperatures to paragraph 2, paragraph 2 of the use of uniform compression screw compression will moisture in the raw material, when through paragraph 3, the moisture of raw material of compression index after reaching eruption phase to the beginning of a paragraph 4, conducted a detonation gas, water into steam by the raw material of the outbreak after extrusion cylinder to vent out, When the water can not be completely discharged after the first dehumidification, the screw is compressed again in the fifth section. In the process of compression, the remaining steam is discharged to the exhaust port of the fourth section to achieve the purpose of rapid dehumidification.

Satisfaction

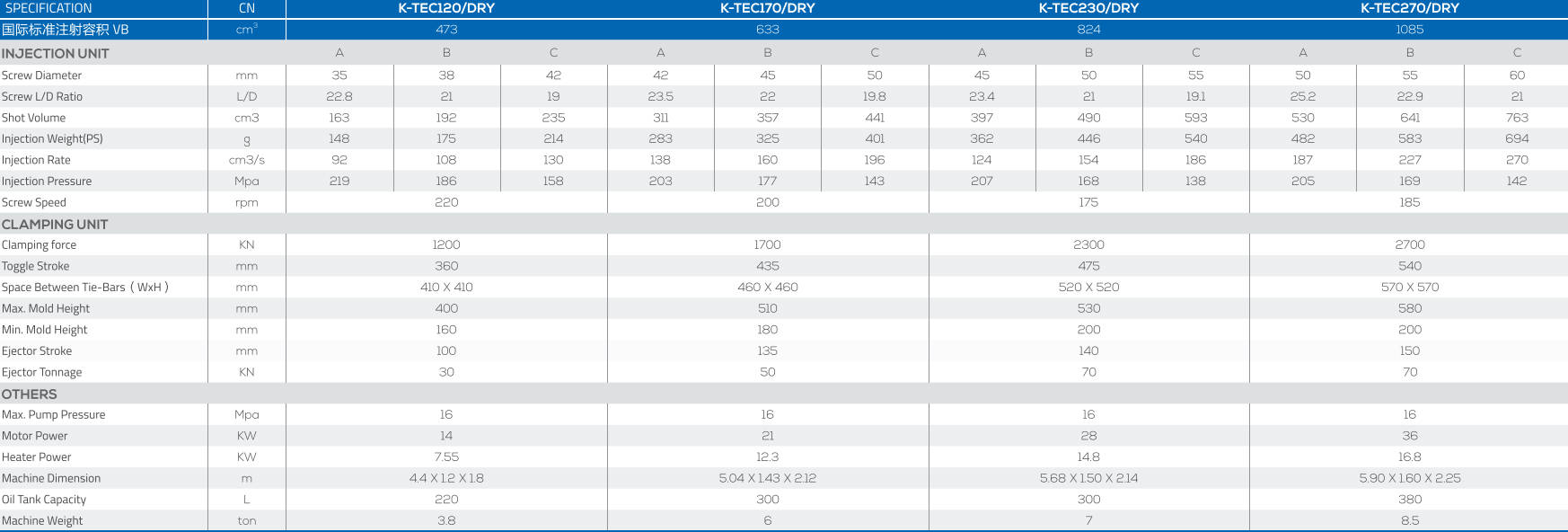

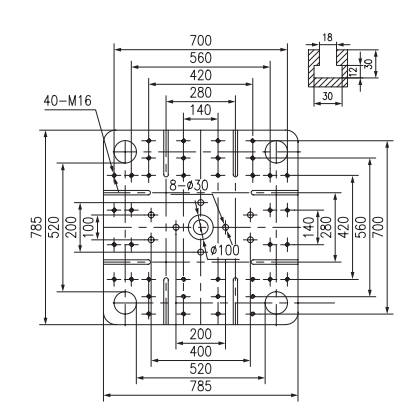

TEMPLATE SIZE

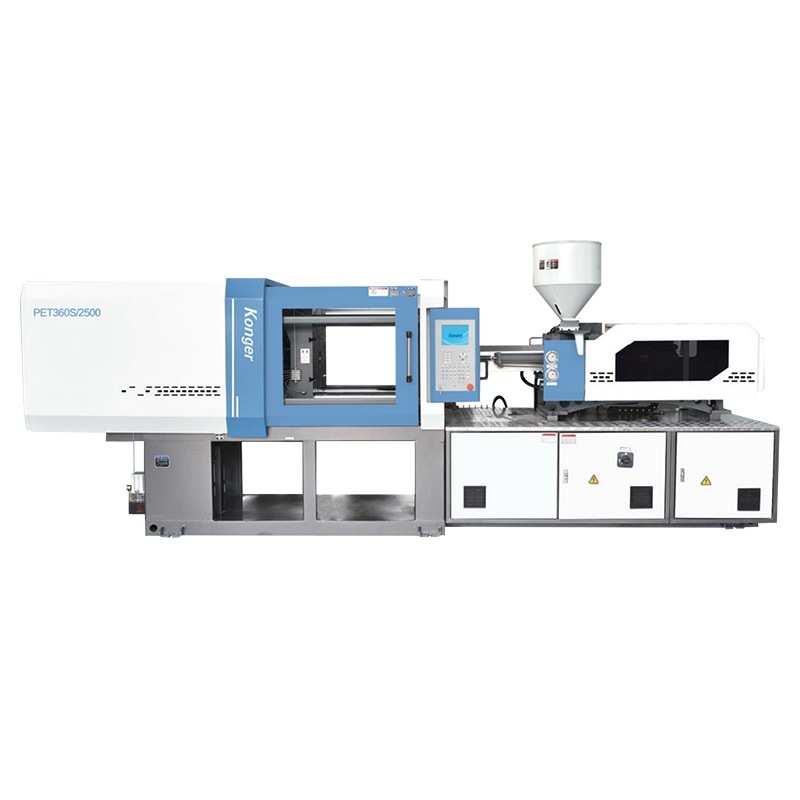

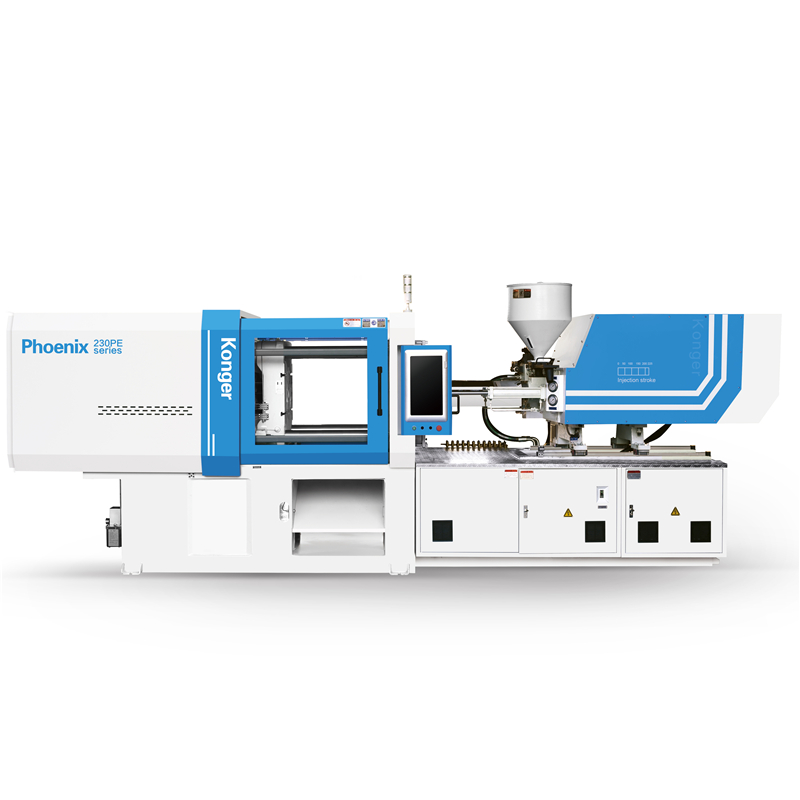

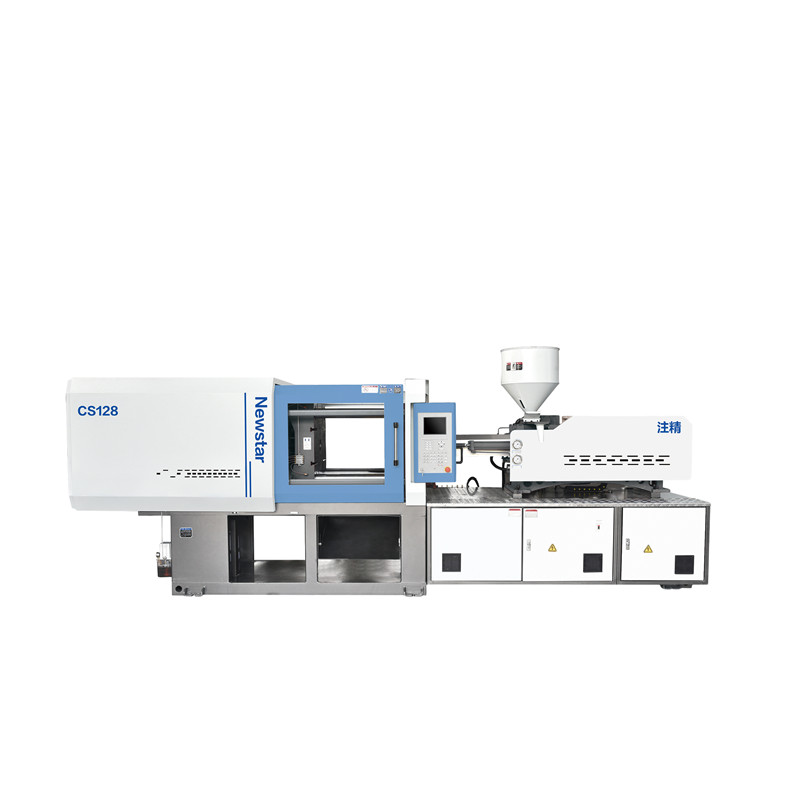

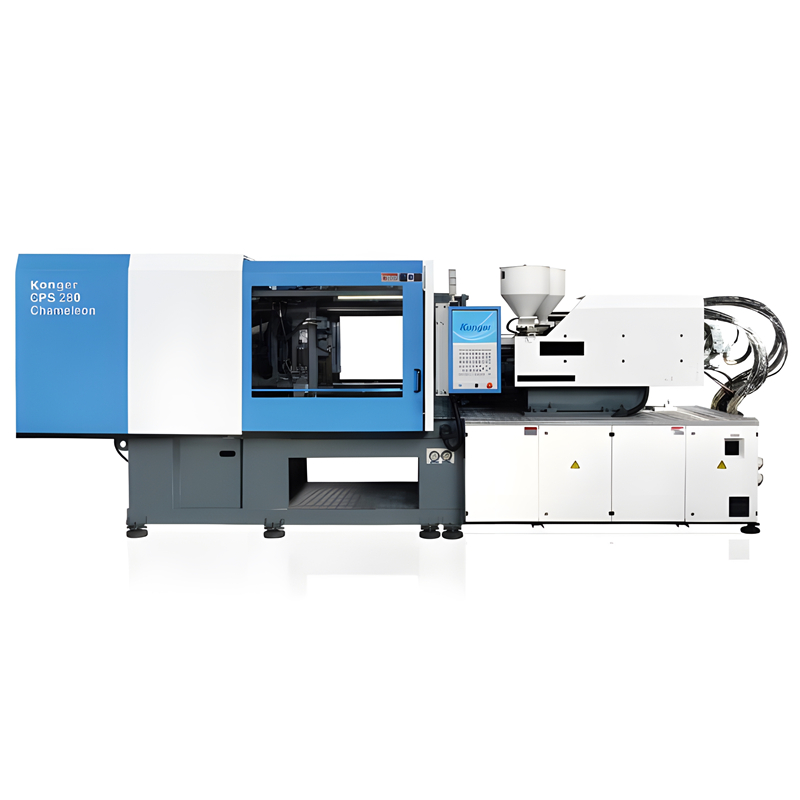

K-TEC120/DRY

K-TEC170/DRY

K-TEC230/DRY

K-TEC270/DRY

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of Quality, Efficiency, Innovation and Integrity. We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for China wholesale Pet Preform Machine Factories - Dry Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Brazil, Florence, Milan, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.