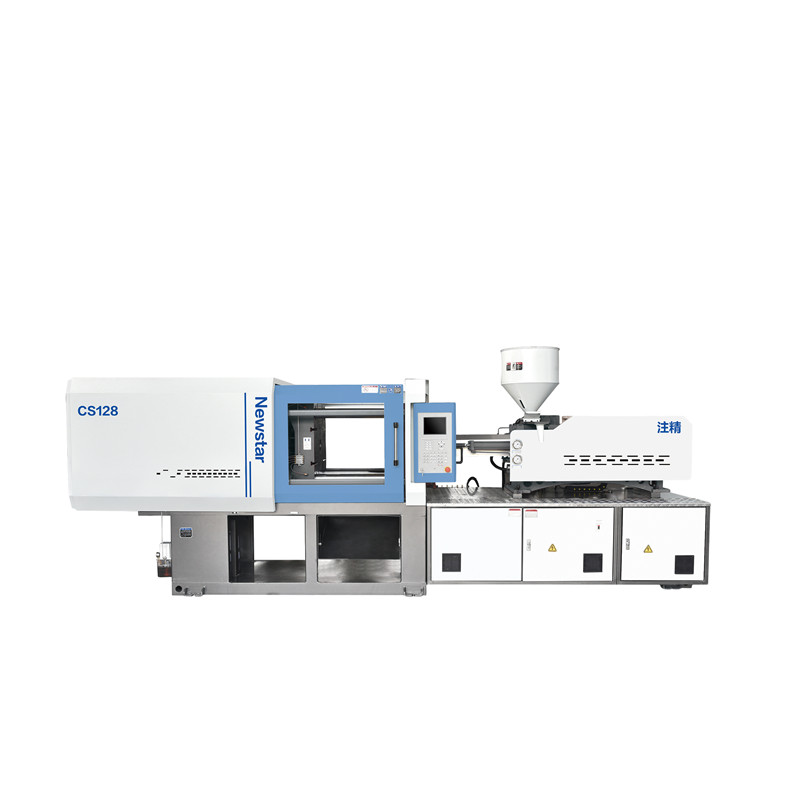

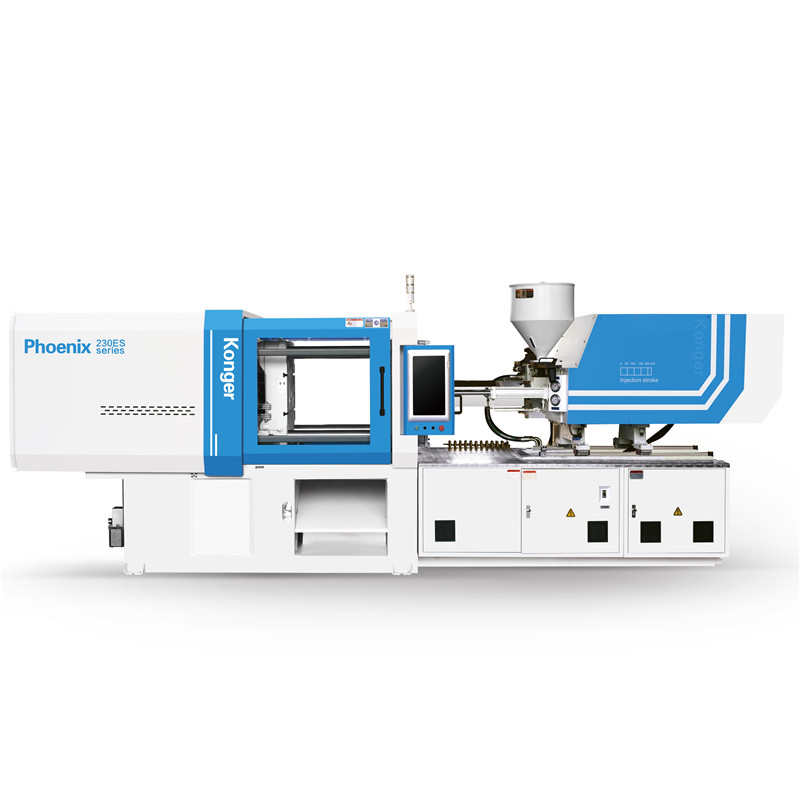

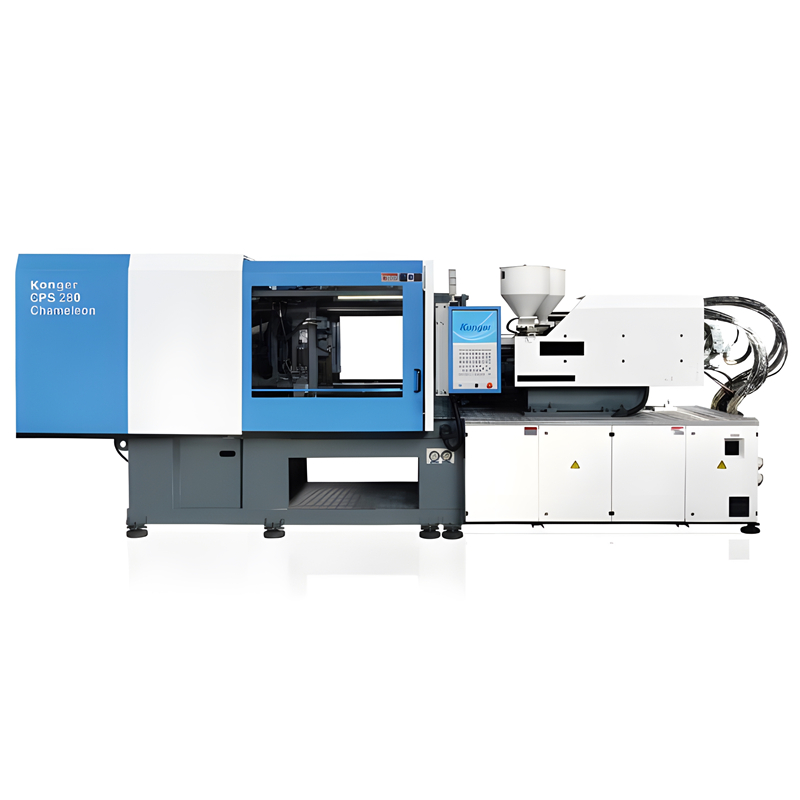

China wholesale Preform Machine Manufacturer - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER

China wholesale Preform Machine Manufacturer - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER

China wholesale Preform Machine Manufacturer - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER Detail:

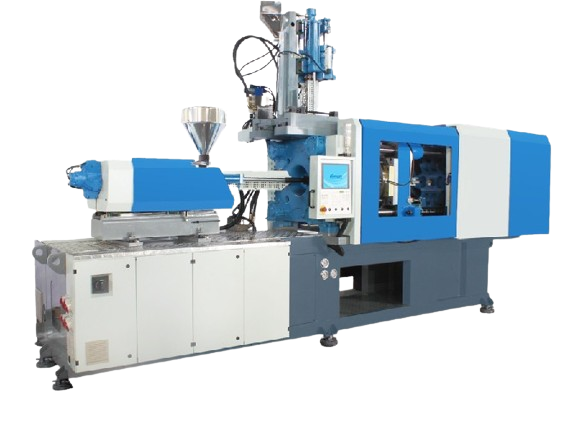

Product advantages

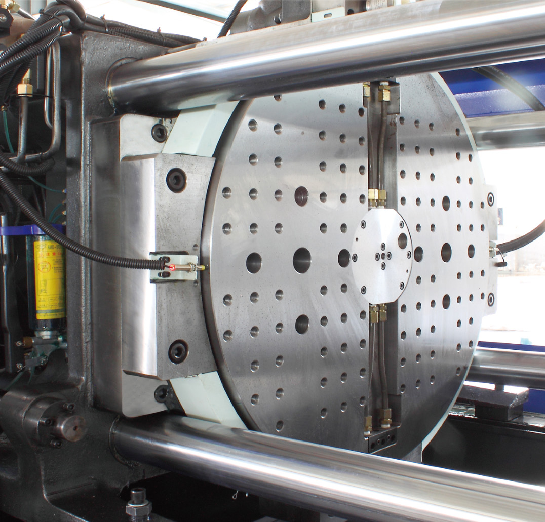

● Without touch the clamp when the turntable running.Can reduce fault because of the abrasion Preciseposition before moulds closed keep the moulds safety.

● Eject force be more stronger because double eject cylinder.

● Reciprocating 180 degree rotation table on movement plate. Can setup two moulds produce the two different color products.

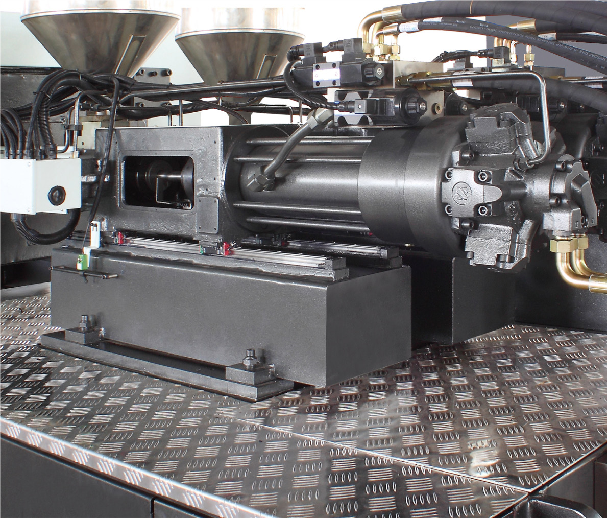

● Single injection cylinder keep injection more stable and precision.

● Low friction drag with precise guide because of injection linear guide.

● Special design all screw L:D=20:1 for all size injection unit setup easy changeable.Can match all customer special requirement.

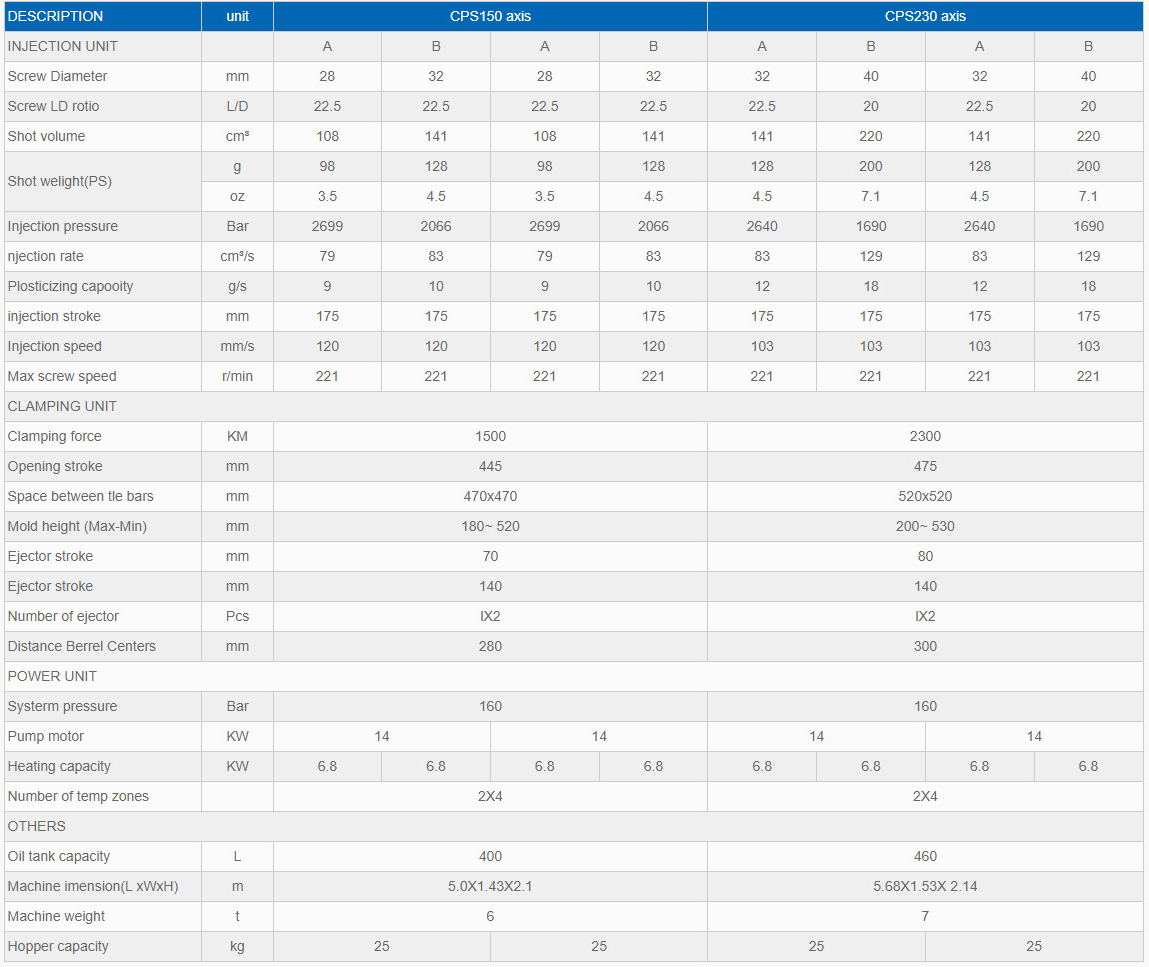

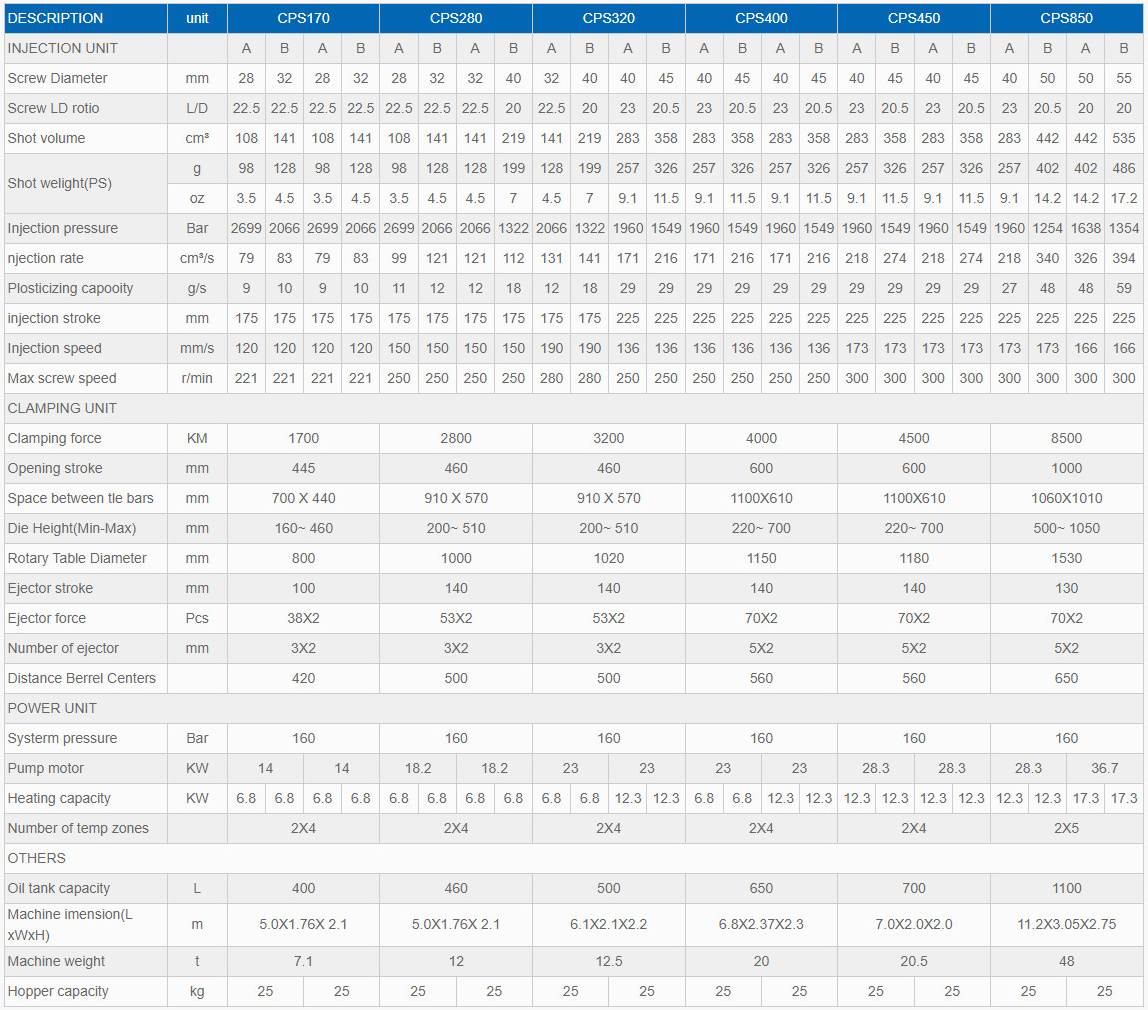

SPECIFICATION

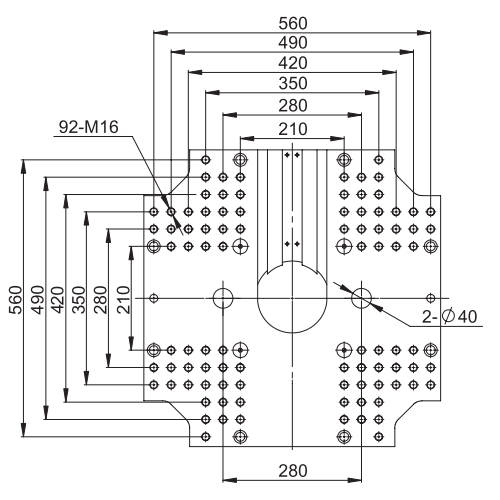

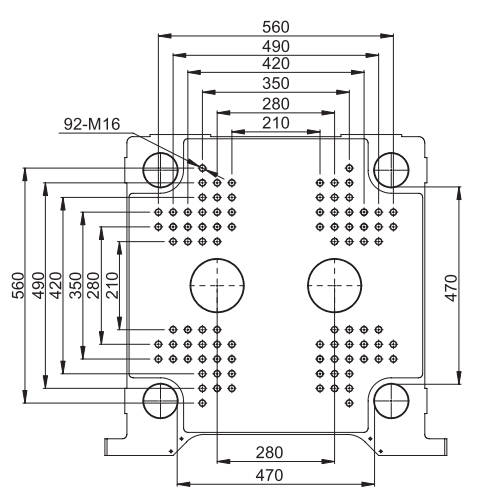

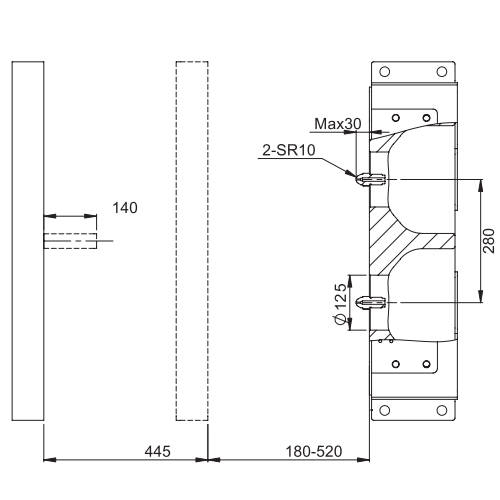

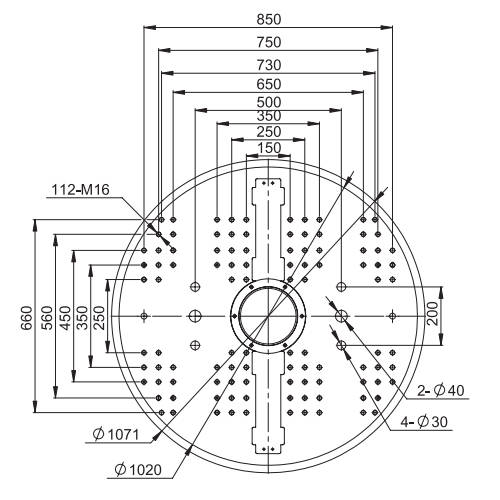

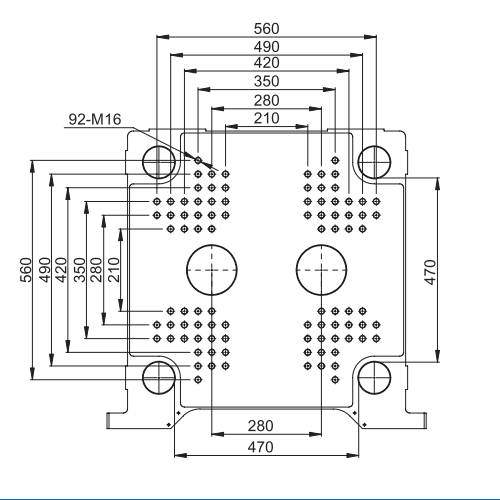

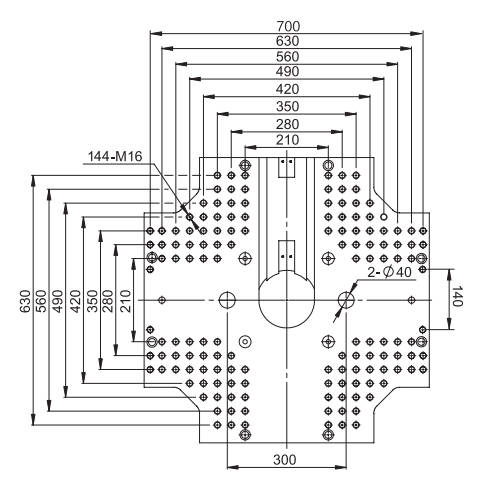

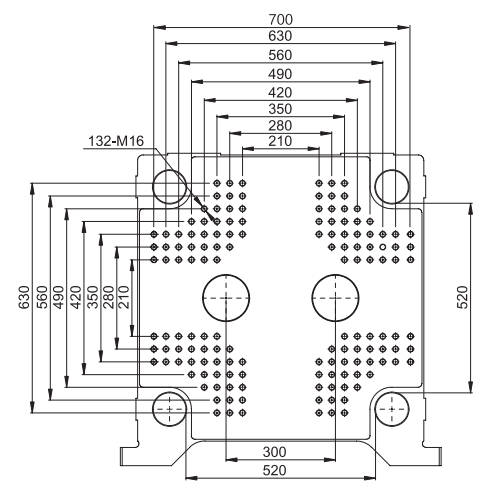

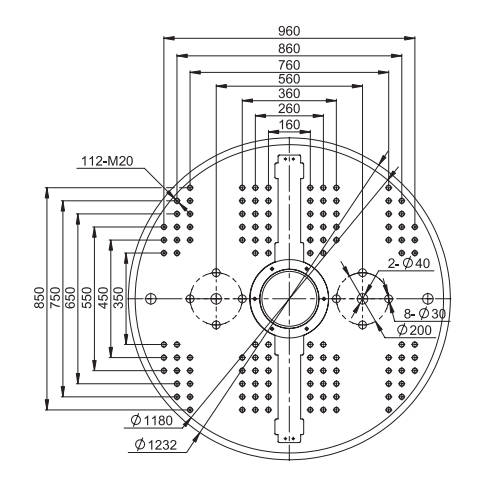

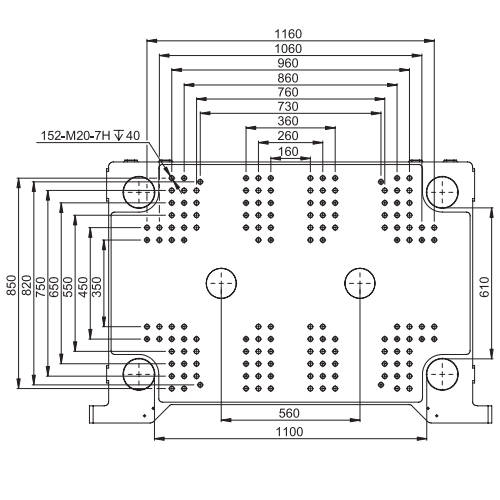

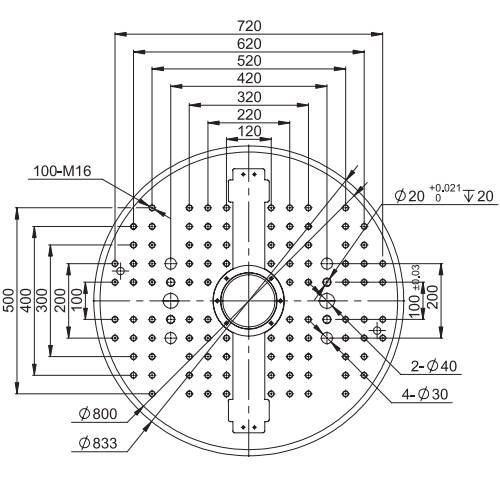

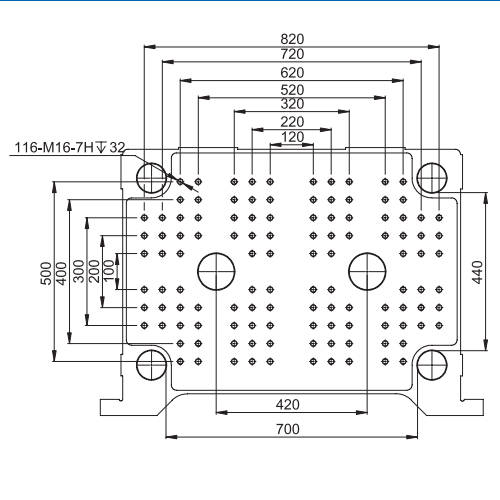

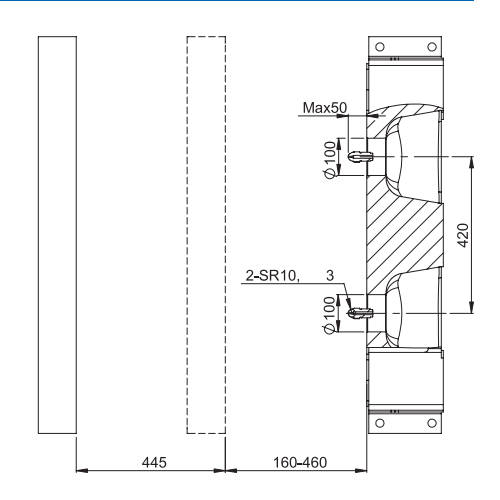

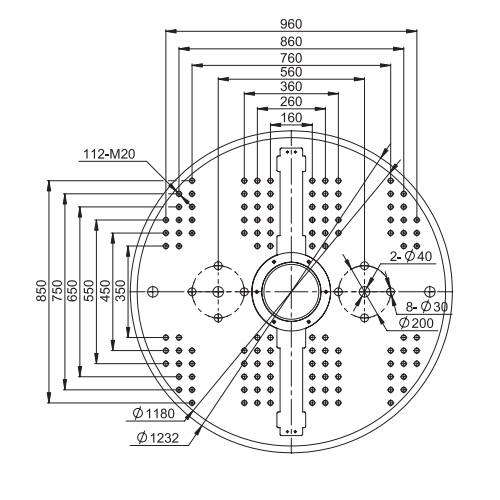

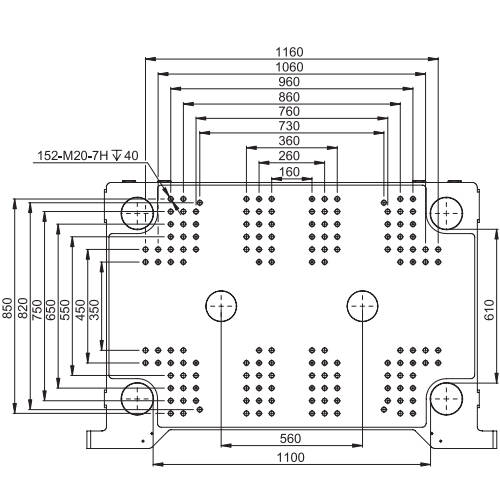

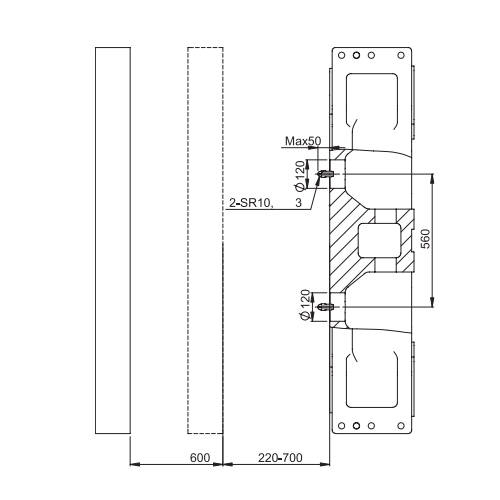

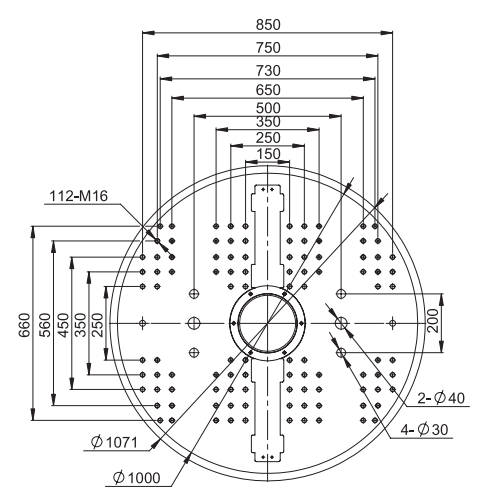

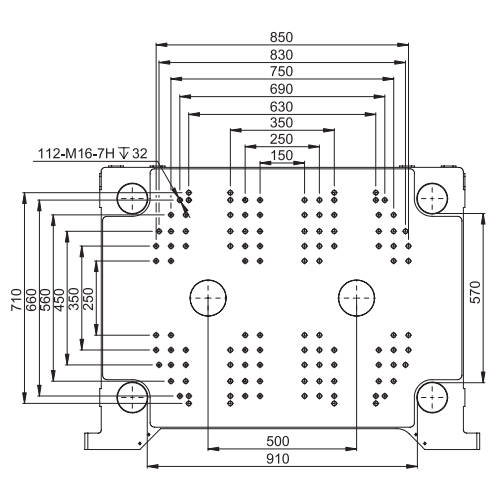

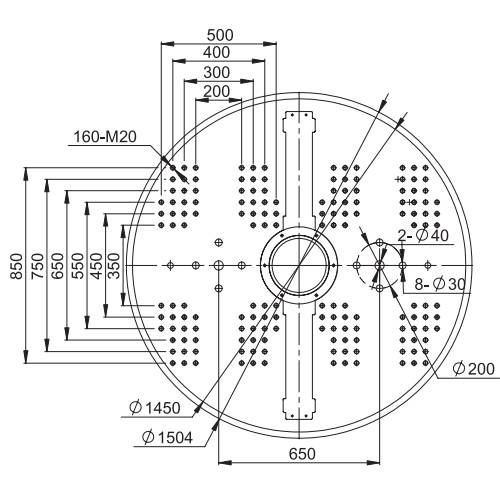

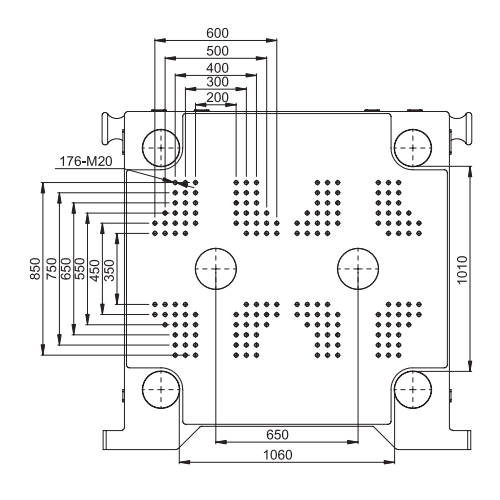

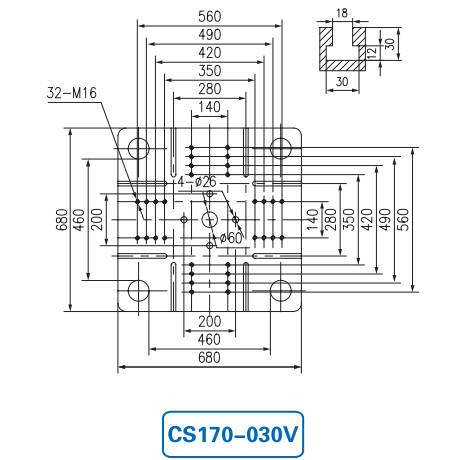

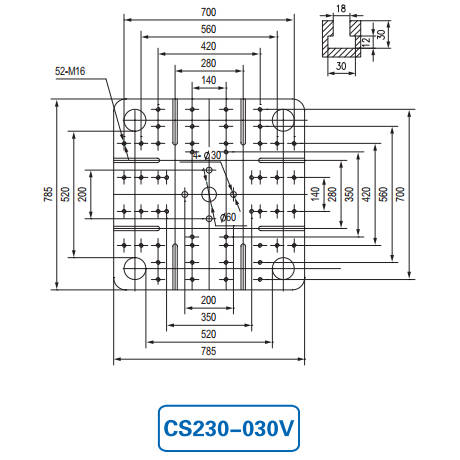

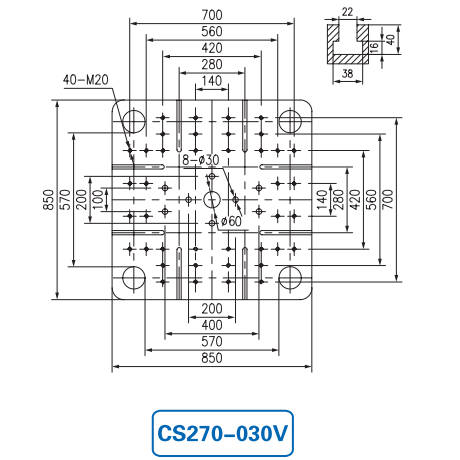

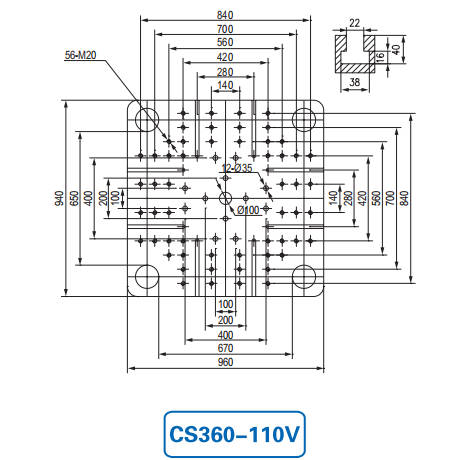

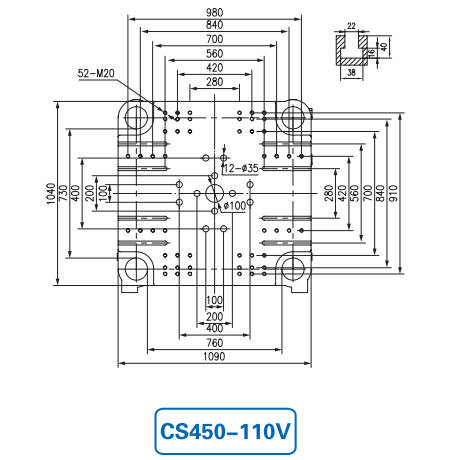

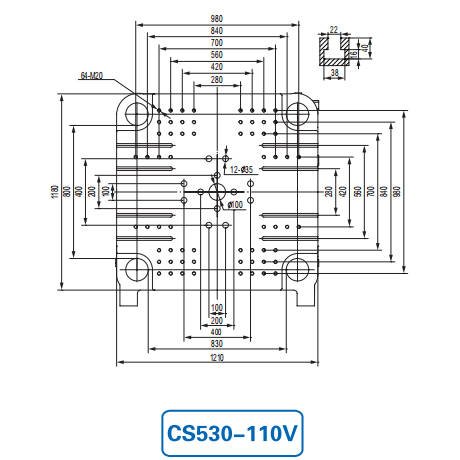

Template plane diagram

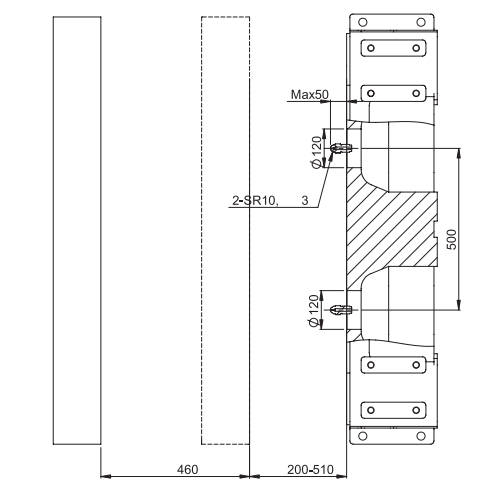

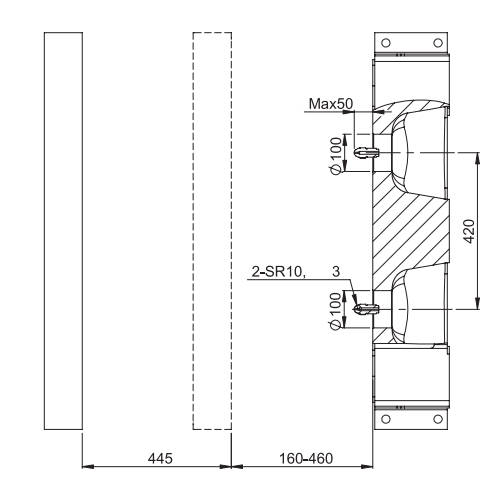

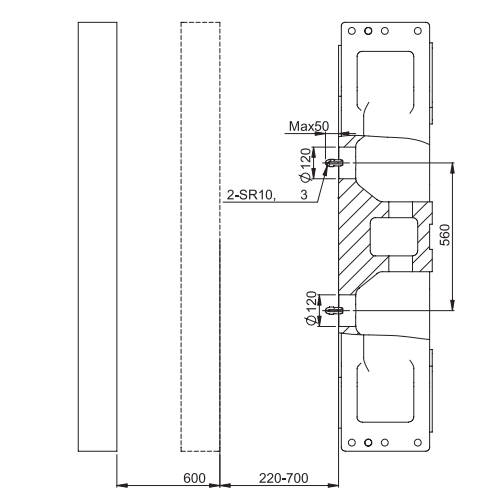

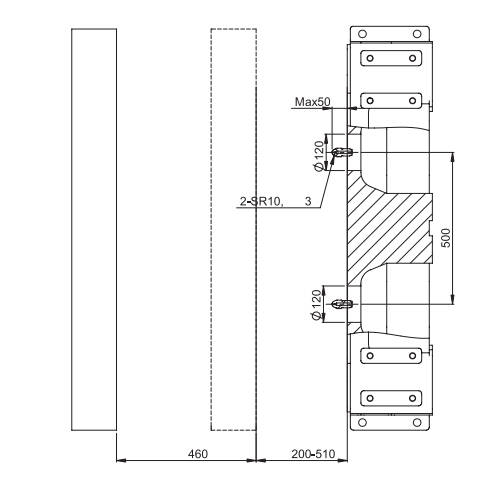

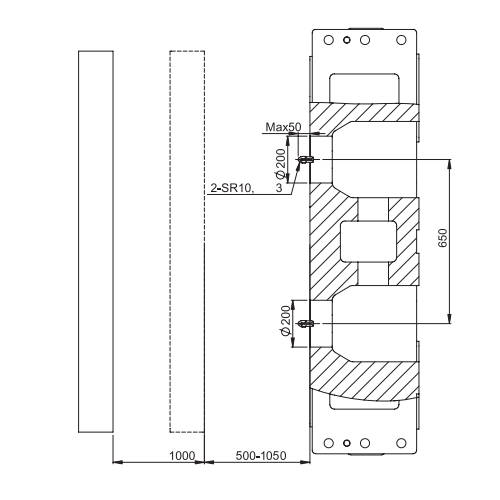

L model clean two color

● Second injection unit setup on plate can save the grand area for customer.

● Reciprocating 180 degree rotation table on movement plate.Can setup one moulds produce the two different color products.

●Efficiently servo gear transmission structure keep rotating high speed with stable and precise position.

● Multi-plate design can suit for all products requirement rotation table or rotation shaft.

● Without touch the clamp when the turntable running. Can reduce fault because of the abrasion. Precise position before moulds closed keep the moulds safety.

CS230-030V

SATISFACTION

| DESCRIPTION | unit | CS170-030V | CS230-030V | CS270-030V | CS360-110V | CS450-110V | CS530-110V | ||||||||||||||||||||||||

| International size rating | cm³ | 633 | 130 | 824 | 130 | 1085 | 130 | 2418 | 358 | 2987 | 358 | 4155 | 358 | ||||||||||||||||||

| INJECTION UNIT | UNIT | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B | A | B | C | A | B |

| Screw Diameter | mm | 42 | 45 | 50 | 22 | 25 | 45 | 50 | 55 | 22 | 25 | 50 | 55 | 60 | 22 | 22 | 65 | 70 | 75 | 35 | 38 | 70 | 75 | 80 | 35 | 38 | 80 | 85 | 90 | 35 | 38 |

| Screw L:D ratio | L/D | 23.5 | 22 | 19.8 | 20 | 20 | 23.4 | 21 | 19.1 | 20 | 20 | 25.2 | 22.9 | 2l | 20 | 20 | 22.5 | 21 | 19.6 | 22.8 | 21 | 22 | 20.5 | 19.2 | 22.8 | 21 | 22.3 | 21 | 19.8 | 22.8 | 21 |

| Shot volume | cm³ | 311 | 357 | 401 | 38 | 49 | 397 | 490 | 593 | 38 | 49 | 530 | 641 | 763 | 38 | 38 | 1161 | 1347 | 1546 | 163 | 192 | 1500 | 1723 | 1960 | 163 | 192 | 2210 | 2495 | 2797 | 163 | 192 |

| Shot weight(PS) | g | 283 | 325 | 441 | 35 | 45 | 362 | 446 | 540 | 35 | 45 | 482 | 583 | 694 | 35 | 35 | 1057 | 1226 | 1407 | 148 | 175 | 1365 | 1568 | 1784 | 148 | 175 | 2011 | 2270 | 2545 | 148 | 175 |

| Injection rate | cm³/s | 138 | 160 | 196 | 40 | 51 | 124 | 154 | 186 | 40 | 51 | 187 | 227 | 270 | 40 | 40 | 337 | 368 | 422 | 90 | 104 | 335 | 384 | 437 | 90 | 104 | 442 | 499 | 560 | 90 | 104 |

| Injection pressure | Mpa | 203 | 177 | 143 | 342 | 265 | 207 | 168 | 138 | 342 | 265 | 205 | 169 | 142 | 342 | 342 | 208 | 179.6 | 156 | 219 | 186 | 199 | 173 | 152 | 219 | 186 | 188 | 167 | 149 | 219 | 186 |

| Max screw speed | r/min | 200 | 260 | 175 | 260 | 185 | 260 | 155 | 205 | 150 | 205 | 120 | 205 | ||||||||||||||||||

| CLAMPING UNIT | |||||||||||||||||||||||||||||||

| Clamping force | KN | 1700 | 2300 | 2700 | 3600 | 4500 | 5300 | ||||||||||||||||||||||||

| Opening stroke | mm | 435 | 475 | 540 | 615 | 740 | 840 | ||||||||||||||||||||||||

| Space between tie bar | mm | 460 X 460 | 520 X 520 | 570 X 570 | 670 X 650 | 760 X 730 | 830 X 800 | ||||||||||||||||||||||||

| Max.mold height | mm | 520 | 530 | 580 | 680 | 780 | 830 | ||||||||||||||||||||||||

| Min.mold height | mm | 180 | 200 | 200 | 250 | 280 | 350 | ||||||||||||||||||||||||

| Ejector stroke | mm | 135 | 140 | 150 | 160 | 200 | 240 | ||||||||||||||||||||||||

| Ejector force | KN | 50 | 70 | 70 | 100 | 150 | 150 | ||||||||||||||||||||||||

| POWER UNIT | |||||||||||||||||||||||||||||||

| Systerm pressure | Bar | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||||||||||||||||

| Pump motor | KW | 18.2 | 11 | 23 | 11 | 23.8 | 11 | 36.7 | 11 | 44 | 11 | 23+28.3 | 11 | ||||||||||||||||||

| Heating capacity | KW | 12.3 | 5.9 | 14.8 | 5.9 | 16.8 | 5.9 | 24.6 | 7.55 | 28.7 | 7.55 | 32.6 | 7.55 | ||||||||||||||||||

| OTHERS | |||||||||||||||||||||||||||||||

| Oil tank capacity | L | 340 | 400 | 430 | 650 | 700 | 800 | ||||||||||||||||||||||||

| Machine dimension(L xWxH) | m | 5.28 X 1.43 X 2.9 | 5.68 X 1.5 X 3.1 | 6.0 X 16 X 3.8 | 7.1 X 1.9 X 3.8 | 7.84 X 1.88 X 4.15 | 8.74 X 2.05 X 4.2 | ||||||||||||||||||||||||

| Machine weight | t | 6.3 | 7.3 | 9.2 | 13.9 | 17.5 | 21.5 | ||||||||||||||||||||||||

Template planediagram

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with China wholesale Preform Machine Manufacturer - Chameleon-CPS Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Sri Lanka, California, Cancun, Since always, we adhering to the open and fair, share to get, the pursuit of excellence, and creation of valuevalues, adhere to theintegrity and efficient, trade-oriented, best way , best valve business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.