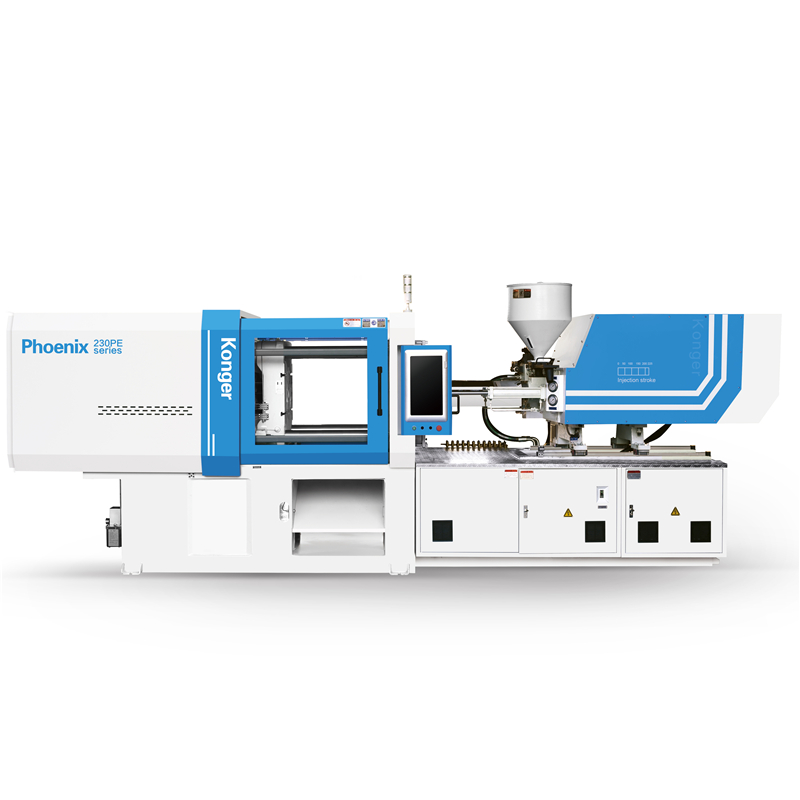

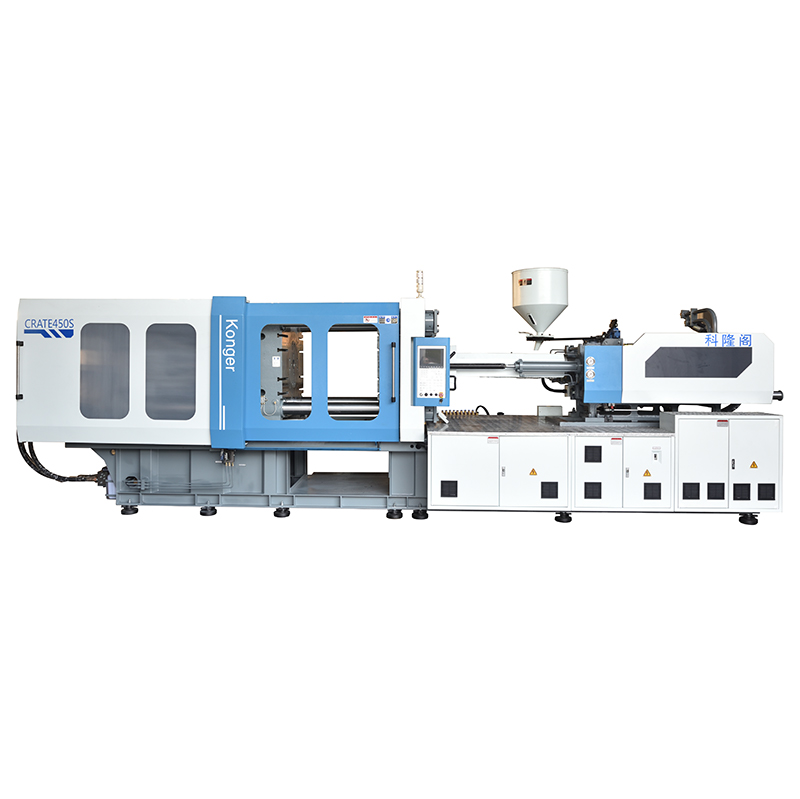

China wholesale Septic Tank Injection Molding Machine Supplier - Crate-Standard Pump Series Plastic Injection Molding Machine – KONGER

China wholesale Septic Tank Injection Molding Machine Supplier - Crate-Standard Pump Series Plastic Injection Molding Machine – KONGER

China wholesale Septic Tank Injection Molding Machine Supplier - Crate-Standard Pump Series Plastic Injection Molding Machine – KONGER Detail:

Product advantages

High-speed clamping unit

The motor automatic clamping unit uses Gear-rack drive, new designed mold closing components by the computer simulation technology. And make the hardening analysis of all the components, optimized internal stress & variable type, in order that the machine moves more stability and smoothly when its running with high speed. It is effective to avoid broke to the plate and tie-bar by the high strength &low stress.

Struction Unit

Innovative designed the high stiffness plate with thicken, the frame with high rigidity materials, the structure with enlarge connected and double-injection in the oblique line, which can make sure the frame’s balance and stability, ensure the usefullife of machines will be longer even if it is running with overload operation.

Injection Unit

Specialised to develop the high strength & special alloy screw, ensure the useful life of machines will be longer. Equiping the double hallway pre-injection motor of the leading technology, can make sure the screw feeds more and faster by the enlarge torque, so that mre improving the plasticing capacity. Adopting the most suitable plan,such as enlagre oil passages and the hole of feeding machines, make sure the stability and speed when its running with the sheet stock, crushing or nozzle materials.

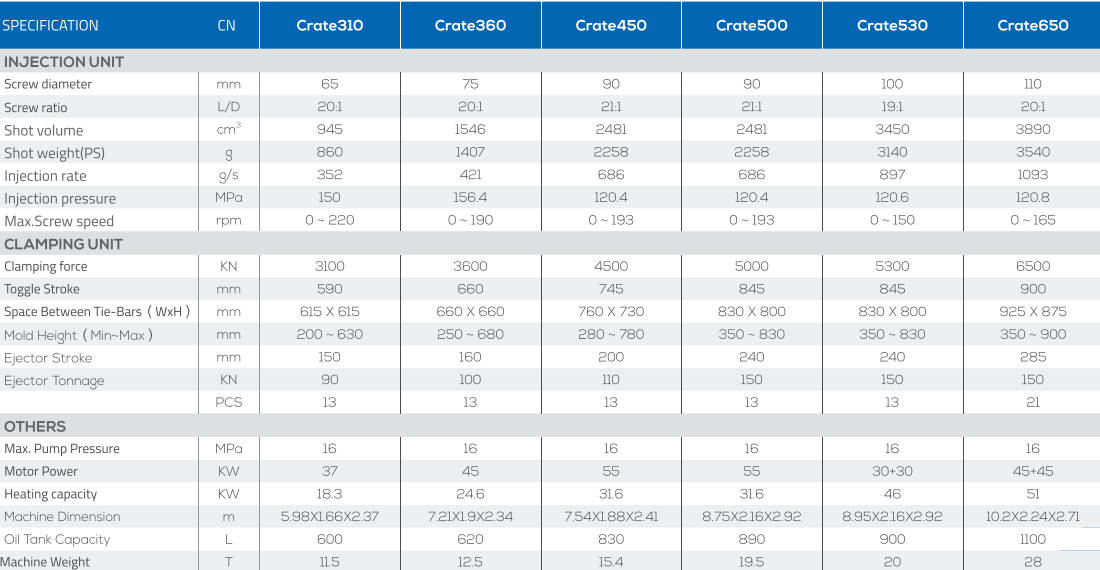

SPECIFICATION

TEMPLATE SIZE

Crate360S

Crate450S

Crate450S/PLUS

Crate500S

Crate500S/PLUS

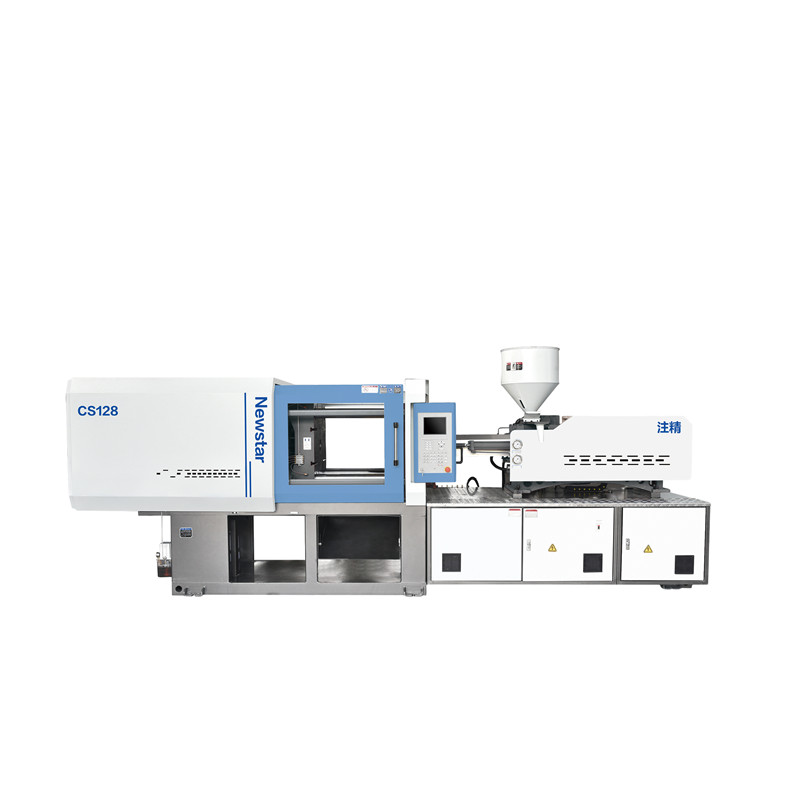

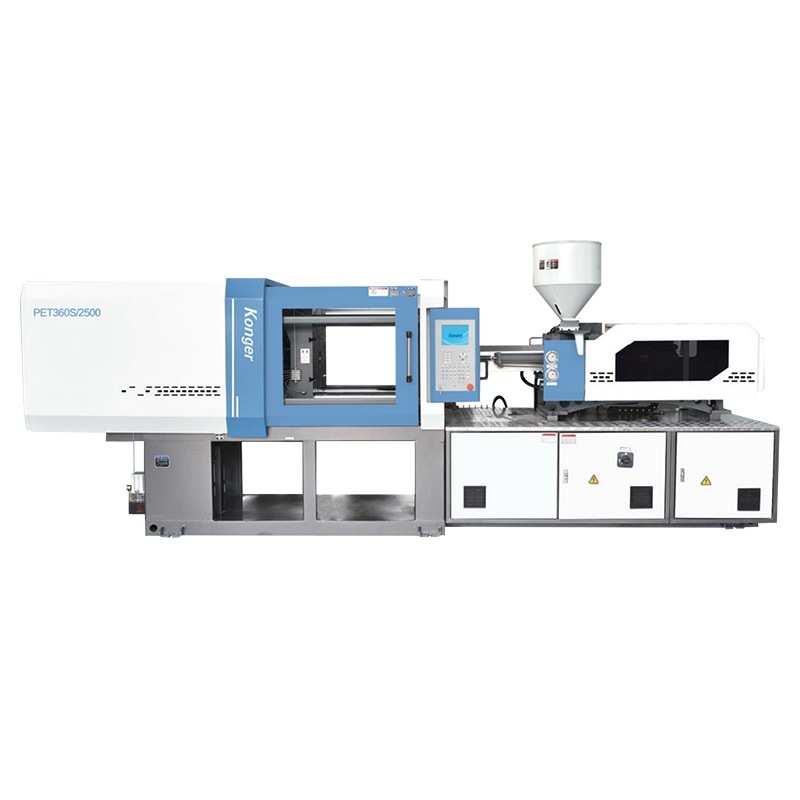

Product detail pictures:

Related Product Guide:

We always do the job to be a tangible group making sure that we can provide you with the top top quality as well as ideal value for China wholesale Septic Tank Injection Molding Machine Supplier - Crate-Standard Pump Series Plastic Injection Molding Machine – KONGER , The product will supply to all over the world, such as: Grenada, Cyprus, Montreal, Our company is working by the operation principle of integrity-based, cooperation created, people oriented, win-win cooperation. We hope we can have a friendly relationship with businessman from all over the world.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!