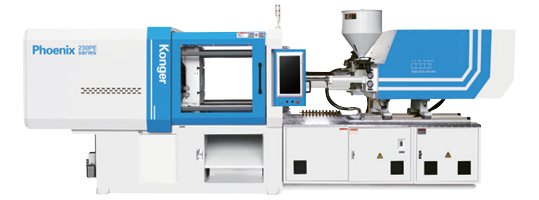

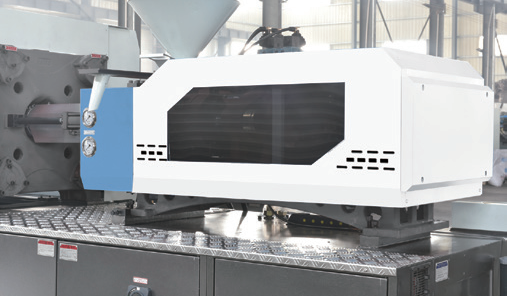

K-TEC170 Standard Plastic Injection Molding Machine

K-TEC170 Standard Plastic Injection Molding Machine

K-TEC series

PHOENIX series

Dry series

Crate series

Bakelite series

PET series

Chameleon series

Product advantages

● World Famous Brands Electric Parts Stable operation

● High-Performance Injection Unit Double cylinder injection system, high injection efficiency maximize control of the precison

Product Description

1

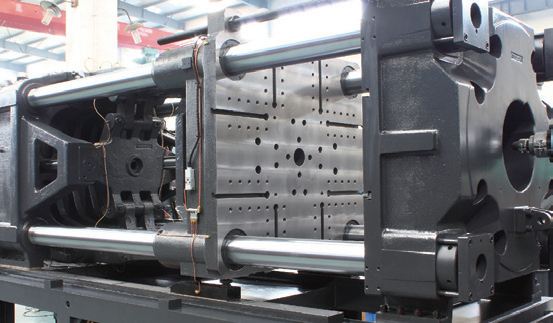

CLAMPING PART

● Tie bar adopt surface hard chromium plating processing.

● With adjustable fect slip block structure.

● Automated centrauzed lubrication system.

● Sgnchronous gear mold adjustment.

● Sensor feet connecting thrust block.

● Optimization design of toggle Structure,clamp of opening and

closing fast and smooth.

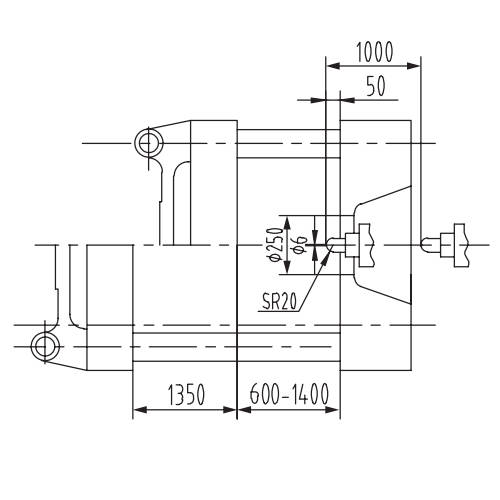

2

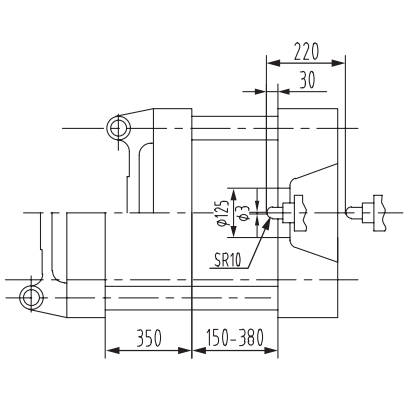

INJECTION UNIT

● Double guide bars, improve inject technology.

● High speed hydraulic motor for screw.

● Screw barrel demolishing vertically makes it easy to replace.

● Injection, holding pressure closed-loop control and precise back

pressure control.

● High-strength mechanical structure design, keep lasting precision.

● Low speed and high torque hydraulic motor drive screw rotation,

excellent performance of plastic.

● Optimized design of screw, wide range of raw materials.

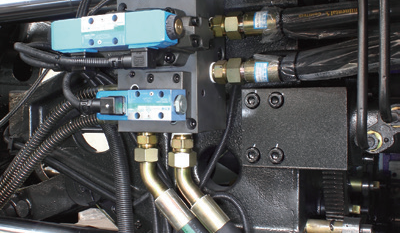

3

HYDRAULIC UNIT

● Adopting Taiwan's technology to produce valve

● Hydraulic circuit designed to meet international safety standards

● No welding pipe in order to achieve stable and reliable maintain

● Automatically read oil temperature

● Adopt international well-know hydraulic components

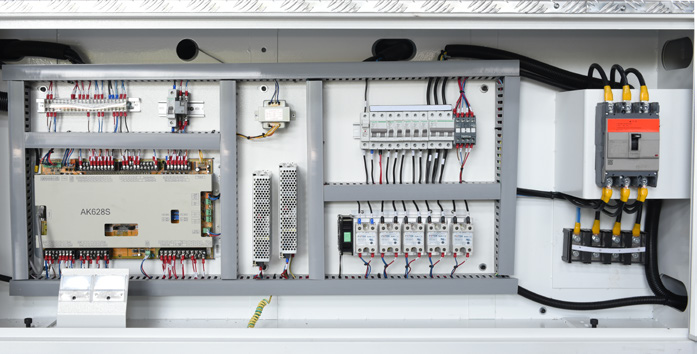

4

ELECTRIC SYSTEM

● Support for multiple languages.

● System with dual-core microprocessors makes it high-speed, anti-noise, low power consumption.

● USB interface can be updated or backup system

parameters.

● Internal inspection Ethernet interface, convenient

connection.

● Smart security features like page prompts, Provide

maintenance tips and warranty.

● Injection pressure, velocity, end and holding pressure curve

display graphical.

● With a record 120 groups and 120 groups to modify alarm

recording function.

● Computer boot self-test function and mechanical failure

alarm.

● I / O simulation capabilities that enable online analog input

and output points.

● Supports simultaneous monitoring of multiple machines

through an office computer, corporate managers may.

differ according to the production process, production

resources planning.

● User-friendly design layout manipulation.

● Servo drives can achieve a variety of control methods of

digital control and analog control.

● Multiple closed-loop monitoring device as standard

transfer mode electric eye, the analyte electric eye, speed

electric eye, etc.

5

FEATURES

6

SERVICE ADVANTAGE

● Supply the bst solutions with technolog support for customer

● Get more details requirement from customer

● Chose the best option for customer.

● Help the customer choose best machins size

● Help the customer give the solutions for auxiliery machines.

● Helo the customer design the electrial/air/water ect at 、

customer factory.

● Give the best special solutions fror customer.

● Delivery the good quality machines on times to customer. And

training customer engineer and workers.

● Delivery on times.

● Setup machines and adjustment free charge.

● Training the engineer and workers free charge.

● All the KONGER machines we will give the service at machines

whole life.

● Prepared the parts for all customer.

7

CORPORATE HONOR

SPECIFICATION

| SPECIFICATION | CN | K-TEC100 | K-TEC120 | K-TEC140 | K-TEC170 | K-TEC230 | K-TEC270 | ||||||||||||

| VB | cm³ | 358 | 450 | 473 | 633 | 824 | 1085 | ||||||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 35 | 38 | 42 | 35 | 38 | 42 | 38 | 42 | 45 | 42 | 45 | 50 | 45 | 50 | 55 | 50 | 55 | 60 |

| Screw L/D Ratio | L/D | 22.8 | 21 | 19 | 22.8 | 21 | 19 | 22.1 | 20 | 18.7 | 23.5 | 22 | 19.8 | 23.4 | 21 | 19.1 | 25.2 | 22.9 | 21 |

| Shot Volume | cm³ | 163 | 192 | 235 | 163 | 192 | 235 | 226 | 277 | 318 | 311 | 357 | 441 | 397 | 490 | 593 | 530 | 641 | 763 |

| Injection Weight(PS) | g | 148 | 175 | 213 | 148 | 175 | 214 | 206 | 252 | 289 | 283 | 325 | 401 | 362 | 446 | 540 | 482 | 583 | 694 |

| njection Rate | cm³/s | 90 | 104 | 128 | 92 | 108 | 130 | 94 | 115 | 132 | 138 | 160 | 196 | 124 | 154 | 186 | 187 | 227 | 270 |

| njection Pressure | MPa | 219 | 186 | 158 | 219 | 186 | 158 | 209 | 171 | 149 | 203 | 177 | 143 | 207 | 168 | 138 | 205 | 169 | 142 |

| Screw Speed | rpm | 205 | 220 | 220 | 200 | 175 | 185 | ||||||||||||

| Clamping force | KN | 1000 | 1200 | 1400 | 1700 | 2300 | 2700 | ||||||||||||

| Toggle Stroke | mm | 350 | 360 | 380 | 435 | 475 | 540 | ||||||||||||

| Space Between Tie-Bars ( WxH) | mm | 370X370 | 410X410 | 420X420 | 460X460 | 520X520 | 570X570 | ||||||||||||

| Max Mold Height | mm | 380 | 430 | 450 | 520 | 530 | 580 | ||||||||||||

| Min.Mald Height | mm | 150 | 160 | 160 | 180 | 200 | 200 | ||||||||||||

| Ejector Stroke | mm | 100 | 100 | 120 | 135 | 140 | 150 | ||||||||||||

| Ejector Tonnoge | KN | 30 | 30 | 50 | 50 | 70 | 70 | ||||||||||||

| Max.Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| Motor Power | KW | 11 | 14 | 14 | 21 | 28 | 36 | ||||||||||||

| Heater Power | KW | 7.55 | 755 | 9.3 | 12.3 | 148 | 168 | ||||||||||||

| Mochine Dimension | m | 4.2X1.2X1.79 | 4.4x1.2X1.8 | 4.48X1.33X1.90 | 5.18X1.40X2.12 | 5.58X1.50x2.4 | 6.0X1.60X2.25 | ||||||||||||

| OilTank Capacity | L | 190 | 220 | 270 | 300 | 300 | 380 | ||||||||||||

| Machine Weight | tom | 3.5 | 38 | 4.3 | 6 | 7 | 8.5 | ||||||||||||

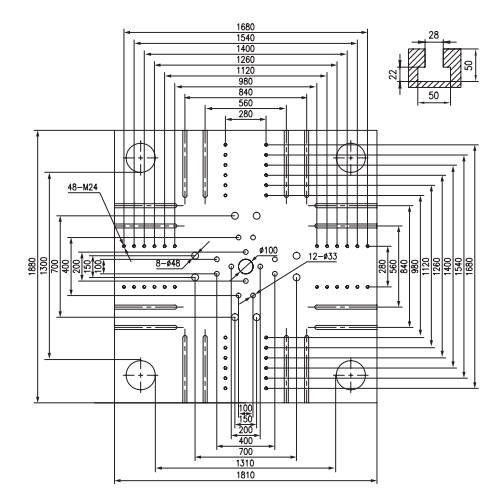

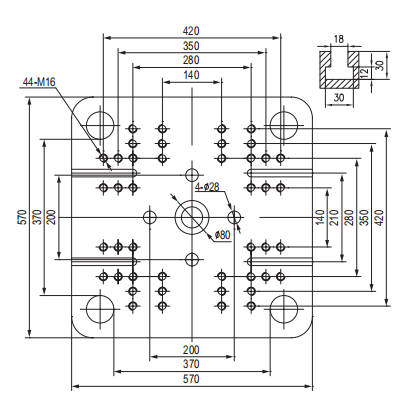

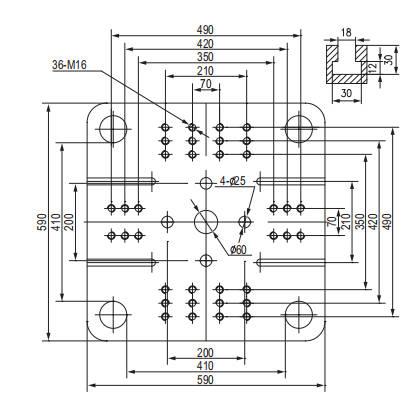

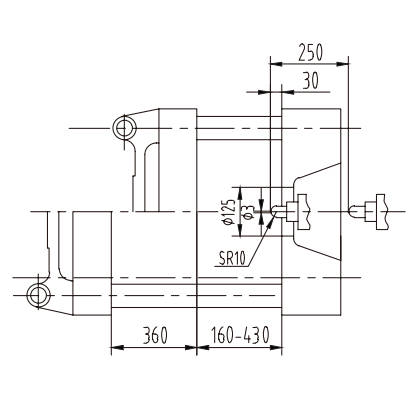

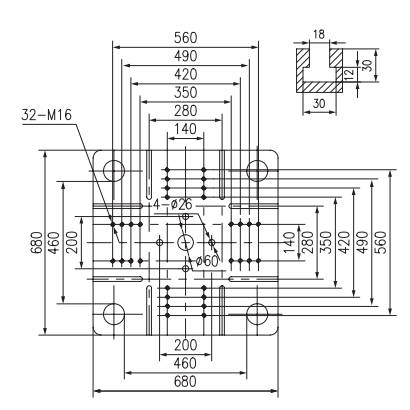

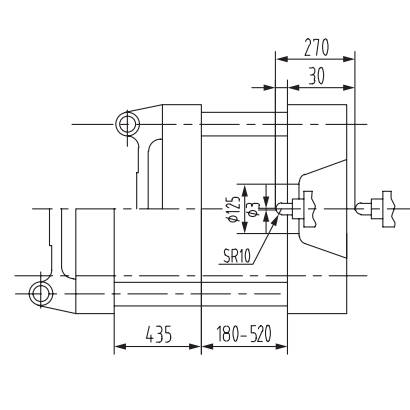

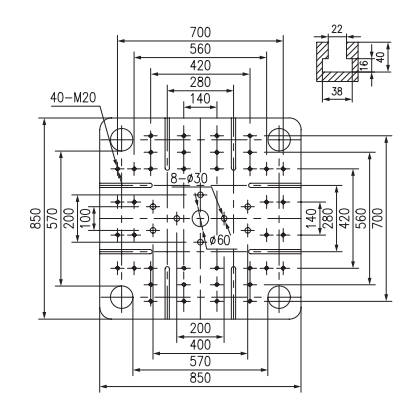

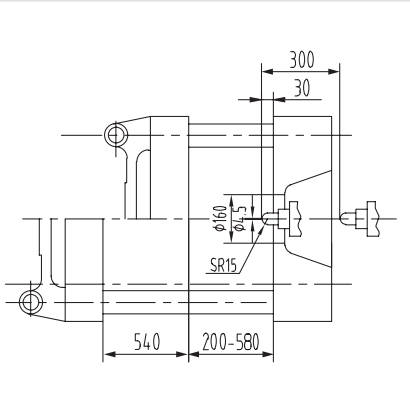

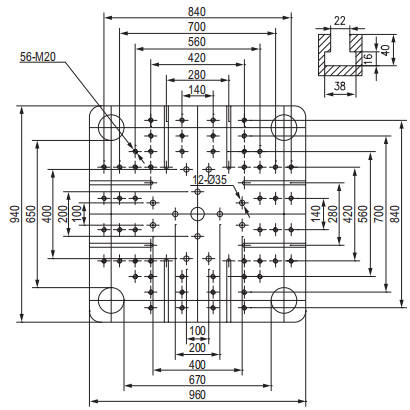

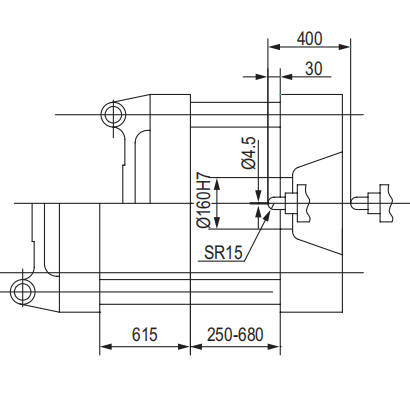

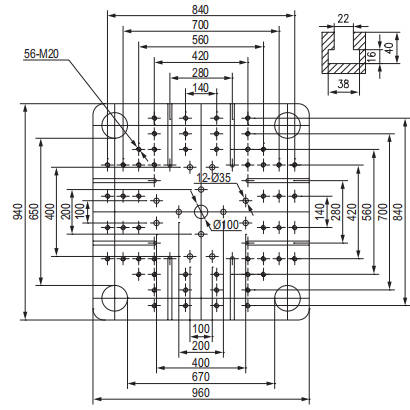

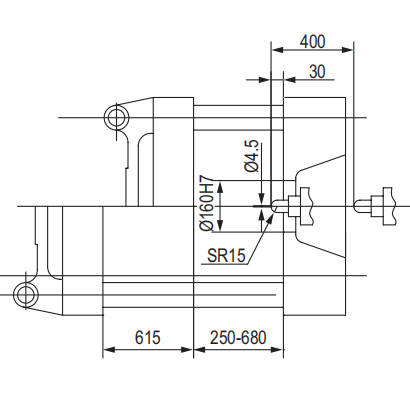

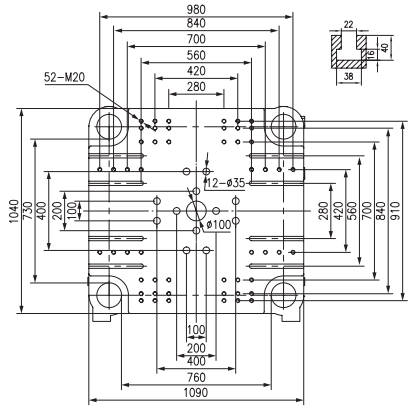

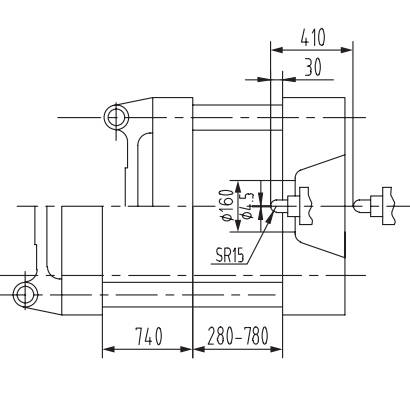

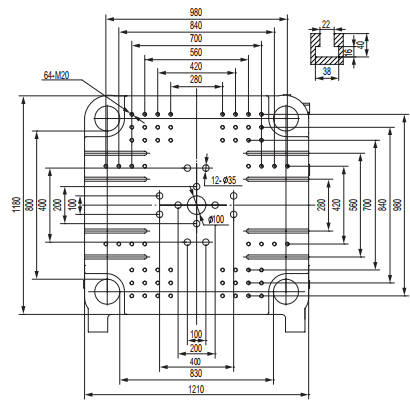

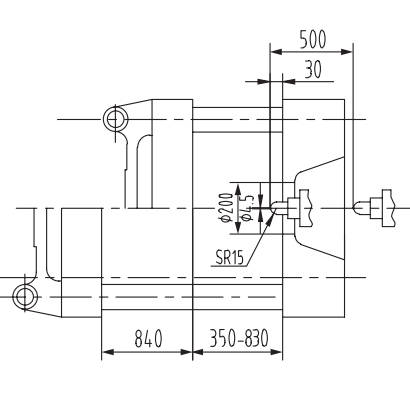

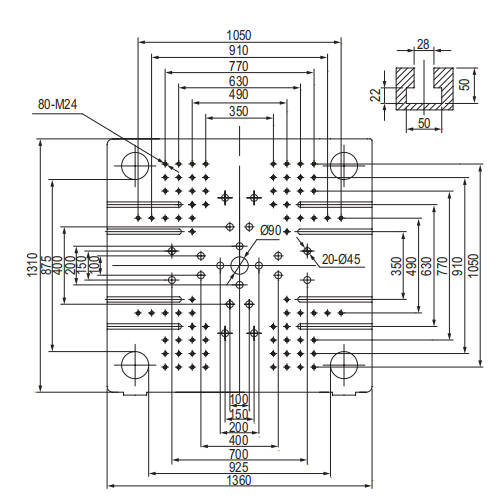

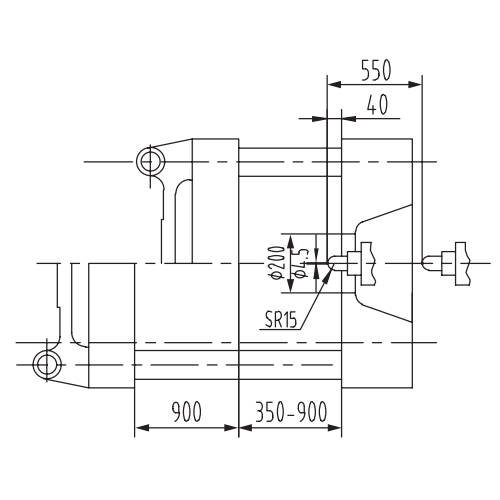

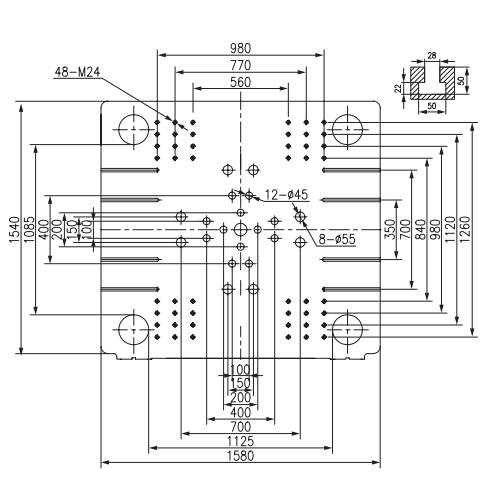

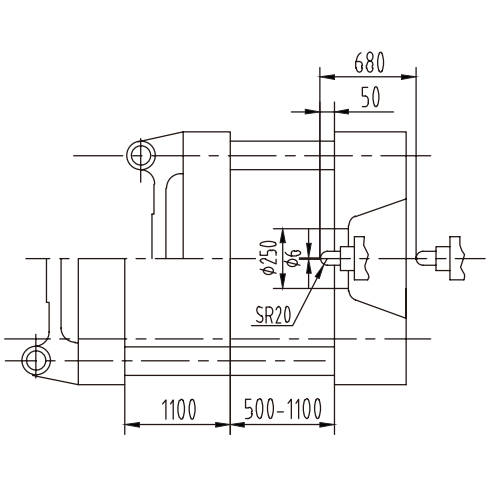

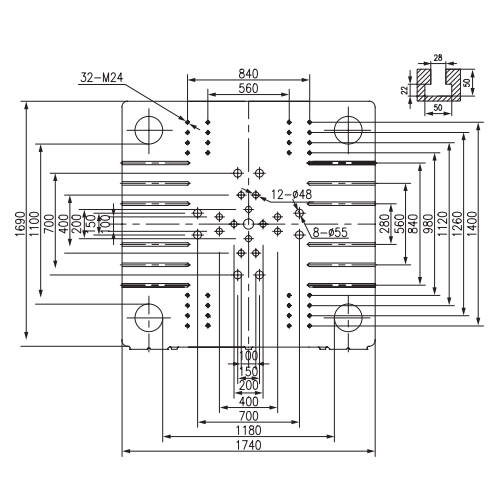

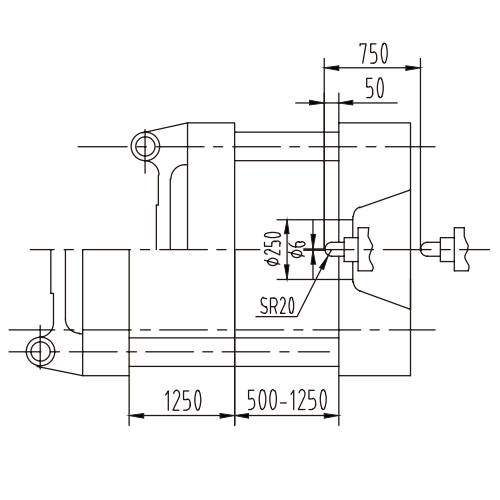

TEMPLATE SIZE

K-TEC100

K-TEC120

K-TEC140

K-TEC170

K-TEC230

K-TEC270

SPECIFICATION

| SPECIFICATION | CN | K-TEC310 | K-TEC320 | K-TEC360 | K-TEC400 | K-TEC450 | K-TEC500 | ||||||||||||

| VB | cma | 1354 | 1354 | 2418 | 2418 | 2987 | 2987 | ||||||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 55 | 60 | 65 | 55 | 60 | 65 | 65 | 70 | 75 | 65 | 70 | 75 | 70 | 75 | 80 | 70 | 75 | 80 |

| Screw L/D Ratio | L/D | 22.9 | 21 | 19.4 | 22.9 | 21 | 19.4 | 22.5 | 21 | 19.6 | 22.6 | 21 | 19.6 | 22 | 20.5 | 19.2 | 22 | 20.5 | 19.2 |

| Shot Volume | cm³ | 677 | 805 | 945 | 677 | 805 | 945 | 1161 | 1347 | 1546 | 1161 | 1347 | 1546 | 1500 | 1723 | 1960 | 1500 | 1723 | 1960 |

| Injection Weight(PS) | g | 616 | 733 | 860 | 616 | 733 | 860 | 1057 | 1226 | 1407 | 1057 | 1226 | 1407 | 1365 | 1568 | 1784 | 1365 | 1568 | 1784 |

| njection Rate | cm³/s | 2235 | 266 | 312.2 | 2235 | 266 | 312.2 | 337 | 368 | 422 | 337 | 368 | 422 | 335 | 384 | 437 | 335 | 384 | 437 |

| njection Pressure | MPa | 200 | 168 | 143 | 200 | 168 | 143 | 208 | 179.6 | 156 | 208 | 179 | 156 | 199 | 173 | 152 | 199 | 173 | 152 |

| Screw Speed | rpm | 185 | 185 | 155 | 155 | 150 | 150 | ||||||||||||

| Clamping force | KN | 3100 | 3200 | 3600 | 4000 | 4500 | 5000 | ||||||||||||

| Toggle Stroke | mm | 590 | 615 | 615 | 740 | 740 | 840 | ||||||||||||

| Space Between Tie-Bars ( WxH) | mm | 615X615 | 670X650 | 670X650 | 760X730 | 760X730 | 830X800 | ||||||||||||

| Max Mold Height | mm | 630 | 680 | 680 | 780 | 780 | 830 | ||||||||||||

| Min. Mald Height | mm | 200 | 250 | 250 | 280 | 280 | 350 | ||||||||||||

| Ejector Stroke | mm | 150 | 160 | 160 | 200 | 200 | 240 | ||||||||||||

| Ejector Tonnoge | KN | 30 | 100 | 100 | 150 | 150 | 150 | ||||||||||||

| Max. Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| Motor Power | KW | 36 | 36 | 43 | 43 | 56 | 56 | ||||||||||||

| Heater Power | KW | 18.3 | 18.3 | 246 | 24.6 | 28.7 | 28.7 | ||||||||||||

| Mochine Dimension | m | 6.2X1.66X2.3 | 7.1X1.84X2.34 | 7.1X1.84X2.34 | 7.54X1.88X2.41 | 7.84X1.92X2.41 | 8.54X2.05X2.3 | ||||||||||||

| OilTank Capacity | L | 380 | 450 | 600 | 650 | 700 | 700 | ||||||||||||

| Machine Weight | tom | 9 | 115 | 12.5 | 15 s | 15.4 | 18 | ||||||||||||

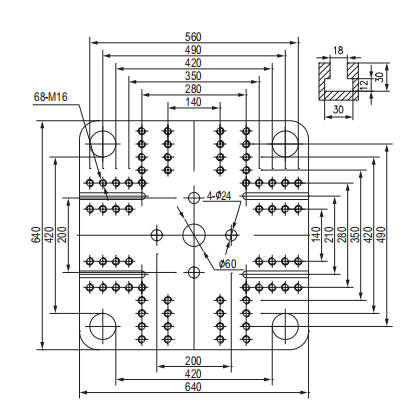

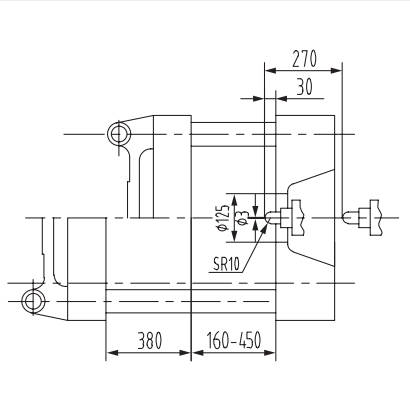

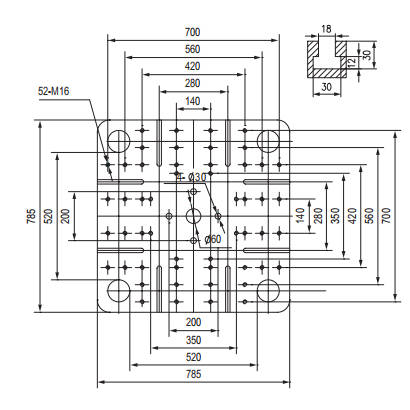

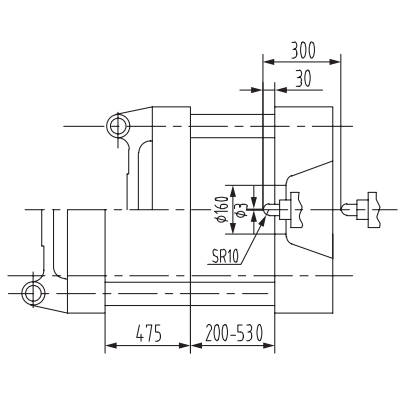

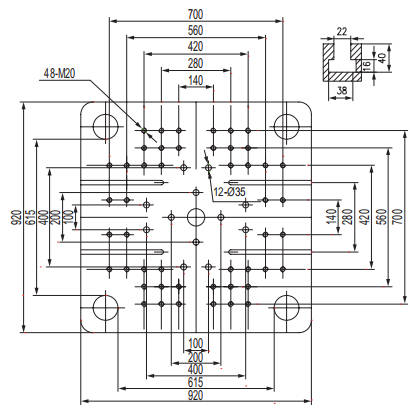

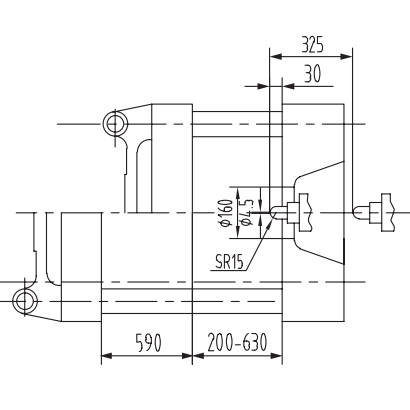

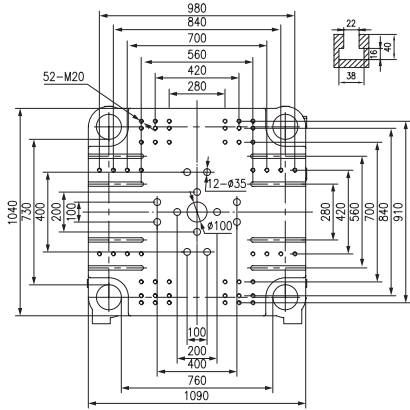

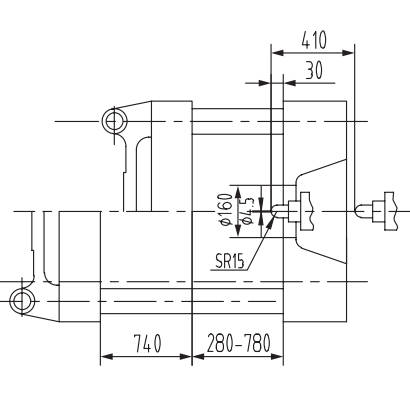

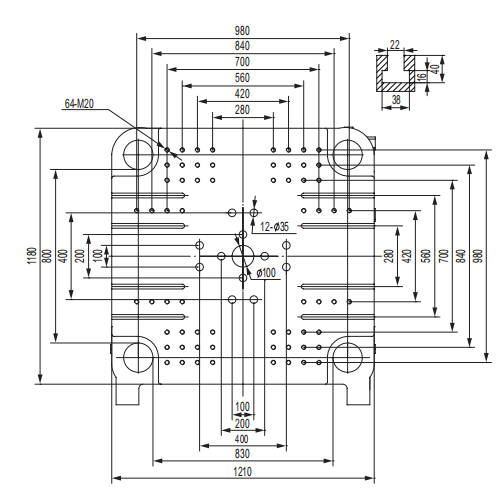

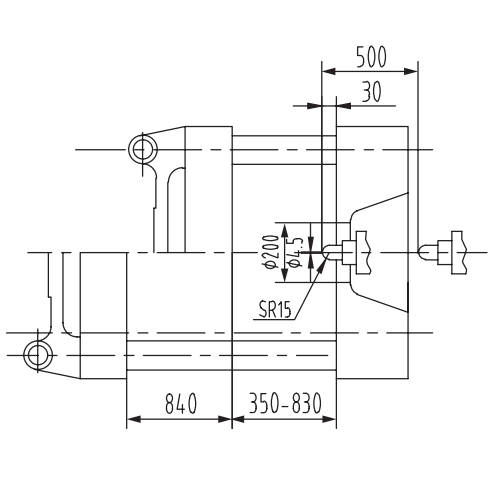

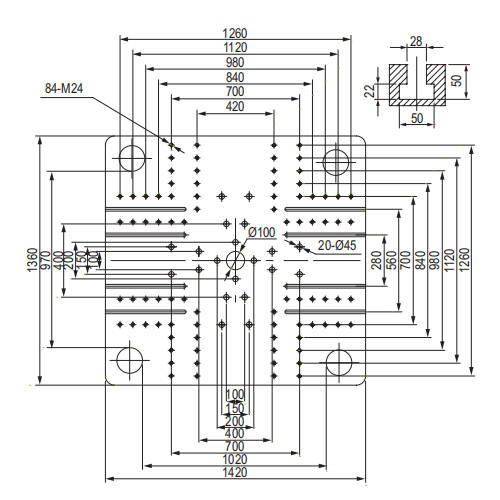

TEMPLATE SIZE

K-TEC310

K-TEC320

K-TEC360

K-TEC400

K-TEC450

K-TEC500

SPECIFICATION

| SPECIFICATION | CN | K-TEC530 | K-TEC650 | K-TEC800 | K-TEC1000 | K-TEC1200 | K-TEC1400 | |||||||||||||||||

| VB | cm³ | 4155 | 4680 | 5706 | 6353 | 9792 | 13060 | |||||||||||||||||

| A | B | C | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | A | B | C | D | ||

| Screw Diameter | mm | 80 | 85 | 90 | 90 | 95 | 100 | 105 | 90 | 95 | 105 | 110 | 90 | 100 | 110 | 115 | 110 | 115 | 120 | 125 | 110 | 120 | 130 | 140 |

| Screw L/D Ratio | L/D | 22.3 | 21 | 19.8 | 20.4 | 19.4 | 18.4 | 175 | 23.2 | 22 | 19.9 | 19 | 25.5 | 23 | 20.9 | 20 | 23 | 22 | 21 | 20.2 | 25.7 | 24 | 22 | 20 |

| Shot Volume | cm³ | 2210 | 2495 | 2797 | 2544 | 2835 | 3141 | 3663 | 2926 | 3260 | 3983 | 4371 | 2920 | 3610 | 4369 | 4778 | 5270 | 5760 | 6272 | 6805 | 627 | 7463 | 8759 | 10158 |

| Injection Weight(PS) | g | 2011 | 2270 | 2545 | 2315 | 2580 | 2858 | 3I51 | 2663 | 2967 | 3624 | 3978 | 2670 | 3300 | 3980 | 4325 | 4796 | 5242 | 5707 | 6193 | 5706 | 6791 | 7970 | 9243 |

| njection Rate | cm³/s | 442 | 499 | 560 | 552 | 612 | 679 | 748 | 574 | 640 | 781 | 858 | 580 | 717 | 867 | 948 | 793 | 867 | 944 | 1024 | 8I5 | 970 | 1138 | 1320 |

| njection Pressure | MPa | 188 | 167 | 149 | 184 | 165 | 149 | 135 | 195 | 175 | 143 | 130 | 216 | 176 | 146 | 133 | 186 | 170 | 156 | 144 | 208 | 175 | 150 | 129 |

| Screw Speed | rpm | 120 | 145 | 125 | 100 | 90 | 90 | |||||||||||||||||

| Clamping force | KN | 5300 | 6500 | 8000 | 100000 | 12000 | 14000 | |||||||||||||||||

| Toggle Stroke | mm | 840 | 900 | 1000 | 1100 | 1250 | 1350 | |||||||||||||||||

| Space Between Tie-Bars ( WxH) | mm | 830X800 | 925X875 | 1020X970 | 1125X1085 | 1180X100 | 1310X1300 | |||||||||||||||||

| Max Mold Height | mm | 830 | 900 | 960 | 1100 | 1250 | 1400 | |||||||||||||||||

| Min.Mald Height | mm | 350 | 350 | 400 | 500 | 500 | 600 | |||||||||||||||||

| Ejector Stroke | mm | 240 | 295 | 300 | 335 | 325 | 360 | |||||||||||||||||

| Ejector Tonnoge | KN | 150 | 150 | 210 | 216 | 245 | 260 | |||||||||||||||||

| Max.Pump Pressure | MPa | 16 | 16 | 16 | 16 | 16 | 16 | |||||||||||||||||

| Motor Power | KW | 28+36 | 43+36 | 43+56 | 43+56 | 56+56 | 43+43+43 | |||||||||||||||||

| Heater Power | KW | 32.6 | 46 | 54.3 | 59 | 661 | 86 | |||||||||||||||||

| Mochine Dimension | m | 8.74X20.5X2.3 | 10.2X2.24X2.71 | 11.8X2.24X2.71 | 12.1X2.64X3 | 12.54X2.66X3.27 | 15.2X3X4.13 | |||||||||||||||||

| OilTank Capacity | L | 800 | 1100 | 1200 | 1400 | 2100 | 2900 | |||||||||||||||||

| Machine Weight | tom | 20 | 28 | 37 | 48 | 55 | 90 | |||||||||||||||||

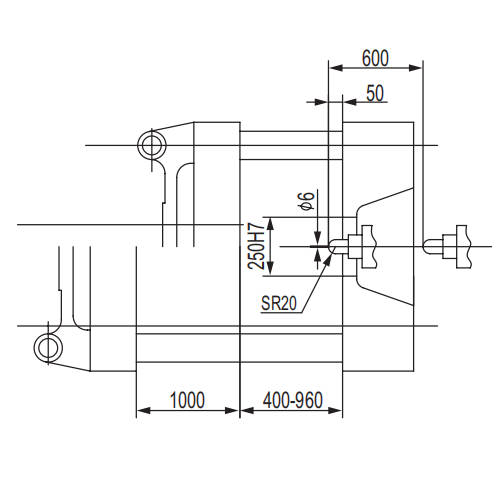

TEMPLATE SIZE

K-TEC530

K-TEC650

K-TEC800

K-TEC1000

K-TEC1200