In the dynamic world of manufacturing, injection molding machine manufacturers play a pivotal role. Leading the industry are renowned names like Haitian International, Milacron Holdings Corp., and Sumitomo Heavy Industries. These brands, along with Engel, Arburg, Nissei Plastic Industrial Co., Husky Injection Molding Systems, and Chen Hsong, set the benchmark for quality and innovation. Their machines shape countless products you use daily, underscoring their significance. Each manufacturer brings unique strengths, contributing to their substantial market share and influence in 2023.

Overview of Injection Molding Machines

Definition and Function

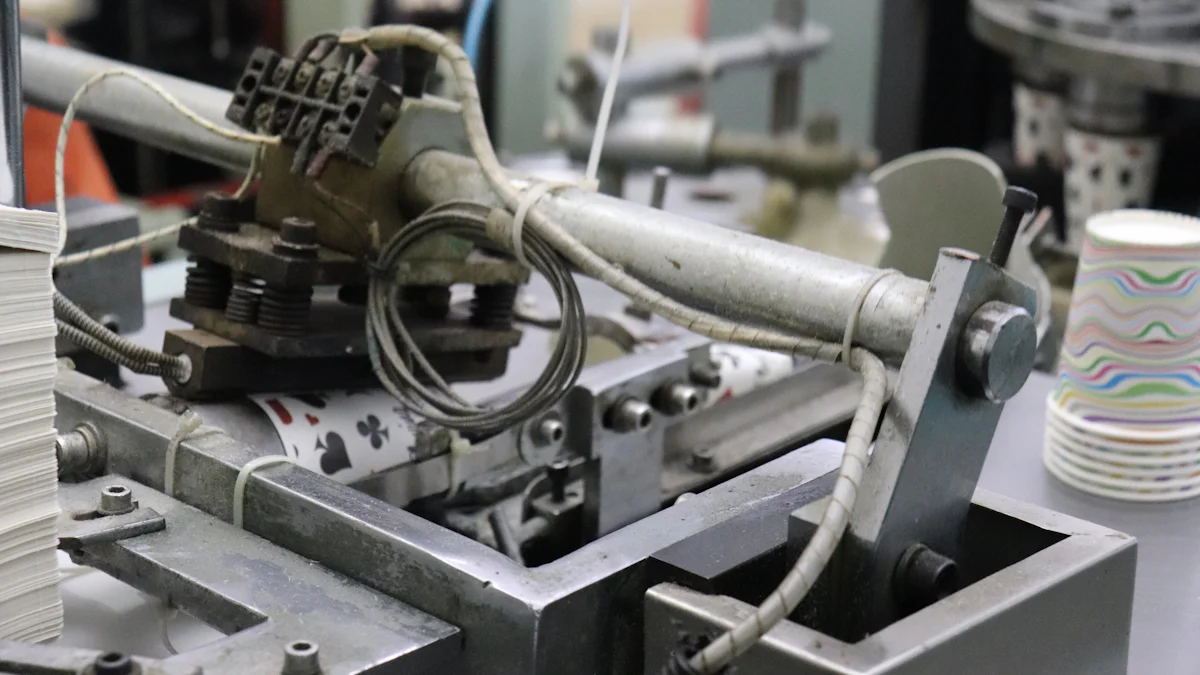

Injection molding is a manufacturing process used to create parts by injecting molten material into a mold. This technique is versatile, allowing you to work with various materials such as metals, glasses, elastomers, and most commonly, thermoplastic and thermosetting polymers. The process begins with small pellets or granules placed into a heated chamber where they melt. The molten material is then injected under pressure into a mold, where it cools and hardens into the desired shape. This method is essential for producing a wide range of products, from auto parts and electronic components to toys and kitchen appliances.

Importance in Manufacturing

Injection molding machines are crucial in the manufacturing industry due to their ability to produce high-quality components with precision and efficiency. These machines enable mass production, making them ideal for creating large quantities of plastic items quickly and consistently. The integration of smart technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), has further enhanced their capabilities. With sensors embedded in the equipment, data is collected and analyzed to optimize performance, reducing the need for human intervention. This advancement not only increases manufacturing rates but also ensures excellent quality and energy efficiency. As a result, injection molding machine manufacturers continue to play a vital role in shaping the future of manufacturing.

Criteria for Top Injection Molding Machine Manufacturers

When evaluating the leading injection molding machine manufacturers, several key criteria come into play. These factors help you determine which brands stand out in the competitive landscape and why they deserve your attention.

Innovation

Innovation serves as a cornerstone for any top-tier manufacturer. Companies like Nissei Plastic Industrial Co., Ltd. exemplify this by consistently pushing the boundaries of technology. Established in 1947, Nissei has a long history of pioneering advancements in the industry. Their commitment to innovation ensures that you receive cutting-edge solutions tailored to meet evolving market demands. By integrating new technologies, these manufacturers enhance machine performance, efficiency, and sustainability, providing you with state-of-the-art equipment that keeps you ahead of the curve.

Reliability

Reliability is another crucial factor when selecting an injection molding machine manufacturer. You need machines that perform consistently under various conditions, ensuring minimal downtime and maximum productivity. Leading manufacturers prioritize quality control and rigorous testing to deliver machines that you can depend on. This reliability translates into long-term cost savings and operational efficiency, making it a vital consideration for your business.

Customer Service

Exceptional customer service distinguishes top manufacturers from the rest. When you invest in an injection molding machine, you require ongoing support and maintenance to ensure optimal performance. Companies that offer comprehensive customer service, including training, technical support, and after-sales assistance, provide you with peace of mind. They understand your needs and work diligently to address any issues promptly, fostering a strong partnership that benefits your operations.

By focusing on innovation, reliability, and customer service, you can identify the injection molding machine manufacturers that align with your specific requirements. These criteria not only highlight the strengths of each brand but also guide you in making informed decisions that enhance your manufacturing capabilities.

Market Presence

Market presence plays a crucial role in determining the success of injection molding machine manufacturers. A strong market presence not only reflects a company’s ability to meet customer demands but also its capacity to adapt to changing industry trends. Let’s explore how some of the top manufacturers establish their market presence.

-

Global Reach: Companies like Nissei Plastic Industrial Co., Ltd. have established a robust global presence. Since its inception in 1947, Nissei has expanded its operations across various international markets. This expansion allows you to access their innovative products and services, no matter where you are located. Their commitment to quality and precision ensures that you receive reliable equipment tailored to your specific needs.

-

Diverse Product Range: A diverse product range enhances a manufacturer’s market presence. By offering a wide array of injection molding machines and related equipment, companies can cater to different industries and applications. This diversity enables you to find solutions that align with your unique requirements, whether you are in automotive, electronics, or consumer goods sectors.

-

Strategic Partnerships: Forming strategic partnerships with local distributors and service providers strengthens a manufacturer’s market presence. These partnerships ensure that you receive timely support and maintenance, enhancing your overall experience. By collaborating with trusted partners, manufacturers can extend their reach and provide you with seamless access to their products and services.

-

Adaptability to Market Trends: Staying ahead of market trends is vital for maintaining a strong presence. Leading manufacturers continuously innovate and adapt their offerings to meet evolving customer demands. This adaptability ensures that you benefit from the latest advancements in technology, such as energy-efficient machines and smart manufacturing solutions.

By focusing on global reach, diverse product offerings, strategic partnerships, and adaptability, injection molding machine manufacturers solidify their market presence. This presence not only reflects their industry leadership but also assures you of their commitment to delivering high-quality solutions that drive your success.

Detailed Profiles of Top 8 Injection Molding Machine Manufacturers

1.Haitian International

https://haitianinter.com/en/

Brief History

Haitian International, founded in 1966, has grown into one of the largest injection molding machine manufacturers globally. The company started in China and quickly expanded its reach, establishing a strong presence in international markets. Haitian’s commitment to innovation and quality has driven its success over the decades.

Key Products

Haitian International offers a diverse range of injection molding machines. Their product lineup includes the Mars Series, known for its energy efficiency and precision. The Jupiter Series caters to large-scale production needs with its robust design. Haitian also provides the Zhafir Series, which focuses on electric injection molding solutions, offering high performance and sustainability.

Unique Selling Points

Haitian International stands out due to its focus on technological advancement and customer satisfaction. The company invests heavily in research and development, ensuring that you receive cutting-edge solutions tailored to your needs. Haitian’s machines are renowned for their reliability and efficiency, making them a preferred choice for manufacturers worldwide.

2.Milacron Holdings Corp.

https://www.milacron.com/

Brief History

Milacron Holdings Corp. has a rich history dating back to 1884. Originally a machine tool company, Milacron evolved into a leading player in the injection molding industry. The company’s long-standing expertise and dedication to innovation have cemented its reputation as a top manufacturer.

Key Products

Milacron offers a comprehensive range of injection molding machines. Their product portfolio includes the Magna Toggle Series, designed for precision and versatility. The Elektron Series provides energy-efficient solutions with advanced control systems. Milacron also features the Roboshot Series, which focuses on all-electric injection molding technology.

Unique Selling Points

Milacron’s unique selling points lie in its commitment to customer-centric solutions and technological excellence. The company emphasizes customization, allowing you to tailor machines to your specific requirements. Milacron’s global service network ensures that you receive prompt support and maintenance, enhancing your operational efficiency.

3.Sumitomo Heavy Industries

https://www.shi.co.jp/english/index.html

Brief History

Sumitomo Heavy Industries, established in 1888, has a long-standing legacy in the manufacturing sector. The company ventured into injection molding in the mid-20th century, leveraging its engineering expertise to deliver high-quality machines. Sumitomo’s dedication to precision and innovation has made it a leader in the industry.

Key Products

Sumitomo offers a range of injection molding machines known for their precision and efficiency. The SE-EV Series features all-electric machines designed for high-speed production. The SHI-Demag Series combines hydraulic and electric technologies, providing versatility and performance. Sumitomo also offers the IntElect Series, focusing on energy-efficient solutions.

Unique Selling Points

Sumitomo Heavy Industries distinguishes itself through its focus on precision engineering and sustainability. The company’s machines are designed to minimize energy consumption while maximizing output. Sumitomo’s commitment to quality and innovation ensures that you receive reliable equipment that meets your manufacturing needs.

4.Konger Machinery

https://www.plasticinjectionmouldingmachinery.com/

Brief History

Konger Machinery, a prominent name in the injection molding industry, began its journey . The company quickly established itself as a leader by focusing on innovation and quality. Konger Machinery commitment to excellence has allowed it to expand its operations globally, serving customers across various continents. This global reach ensures that you have access to their cutting-edge solutions, no matter where your business operates.

Key Products

Konger Machinery offers a diverse range of injection molding machines designed to meet the needs of different industries. Their product lineup includes hydraulic, hybrid, and electric models, each tailored to provide optimal performance. Konger always adhere to technological innovation and brand operation. The K-TEC servo energy-saving series is standard type of injection molding machine. And the clamping force is from l00Ton to 1600Ton, the injection weight is 100g to 12000g.Meanwhile, Konger developed nearly 30 special type injection molding machines such as CPS clean two-color series, CMS mixed two-color series, PET bottle preform series /daily products series etc. Bring more efficient and benefits for our customers. Also Konger provides the whole program solution and one-stop service for customers around the world.

Unique Selling Points

Konger stands out due to its unwavering focus on innovation and customer satisfaction. The company invests heavily in research and development, ensuring that you receive state-of-the-art equipment that meets your specific needs. Konger ‘s machines are renowned for their reliability and efficiency, making them a preferred choice for manufacturers worldwide. Additionally, Konger ‘s commitment to sustainability is evident in their energy-efficient models, which help you reduce operational costs while minimizing environmental impact.

5.Arburg

https://www.arburg.com/en/

Brief History

Arburg, founded in 1923, has a rich history of innovation and excellence in the injection molding sector. The company started as a small family business in Germany and has grown into a global leader. Arburg’s dedication to quality and technological advancement has driven its success, allowing it to serve customers worldwide with innovative solutions.

Key Products

Arburg offers a comprehensive range of injection molding machines and automation solutions. Their product lineup includes the ALLROUNDER series, known for its versatility and precision. These machines cater to various applications, from small-scale production to large industrial projects. Arburg also provides additive manufacturing systems, allowing you to explore new possibilities in production. Their turnkey solutions ensure seamless integration into your existing operations, enhancing efficiency and productivity.

Unique Selling Points

Arburg distinguishes itself through its commitment to innovation and customer-centric solutions. The company’s focus on automation and process technologies ensures that you receive reliable equipment tailored to your needs. Arburg’s machines are designed to optimize performance and reduce energy consumption, providing you with cost-effective and sustainable solutions. Their global presence and extensive service network guarantee that you receive prompt support and maintenance, enhancing your overall experience.

6.Nissei Plastic Industrial Co.

https://www.nisseiplastic.com/en/

Brief History

Nissei Plastic Industrial Co., established in 1947, has a long-standing legacy in the injection molding industry. The company has consistently pushed the boundaries of technology, earning a reputation for innovation and quality. Nissei’s commitment to excellence has allowed it to expand its operations globally, serving customers across various markets.

Key Products

Nissei offers a wide range of advanced injection molding solutions. Their product lineup includes the NEX Series, known for its energy-efficient and high-speed capabilities. The FNX Series provides hybrid solutions, combining the benefits of hydraulic and electric technologies. Nissei also offers the FVX Series, which focuses on large-scale production with robust and reliable machines.

Unique Selling Points

Nissei Plastic Industrial Co. stands out due to its focus on innovation and customer satisfaction. The company’s commitment to research and development ensures that you receive cutting-edge solutions tailored to your needs. Nissei’s machines are renowned for their precision and efficiency, making them a preferred choice for manufacturers worldwide. Their global reach and extensive service network guarantee that you receive prompt support and maintenance, enhancing your operational efficiency.

7.Husky Injection Molding Systems

https://www.husky.co/en/

Brief History

Husky Injection Molding Systems began its journey in 1953. Founded in Canada, the company quickly established itself as a leader in the injection molding industry. Over the years, Husky expanded its operations globally, serving customers across various continents. This global reach ensures that you have access to their innovative solutions, no matter where your business operates.

Key Products

Husky offers a comprehensive range of injection molding machines and related equipment. Their product lineup includes the HyPET Series, known for its high-performance capabilities in PET preform manufacturing. The Hylectric Series provides energy-efficient solutions with advanced control systems. Husky also features the UltraShot Injection System, which focuses on precision and speed, ensuring optimal performance for your production needs.

Unique Selling Points

Husky stands out due to its commitment to innovation and customer satisfaction. The company invests heavily in research and development, ensuring that you receive state-of-the-art equipment tailored to your specific requirements. Husky’s machines are renowned for their reliability and efficiency, making them a preferred choice for manufacturers worldwide. Additionally, Husky’s focus on sustainability is evident in their energy-efficient models, which help you reduce operational costs while minimizing environmental impact.

8.Chen Hsong

https://chenhsong.com/

Brief History

Chen Hsong, founded in 1958, has grown into one of the largest injection molding machine manufacturers in Asia. The company started in Hong Kong and quickly expanded its reach, establishing a strong presence in international markets. Chen Hsong’s dedication to quality and technological advancement has driven its success over the decades.

Key Products

Chen Hsong offers a diverse range of injection molding machines. Their product lineup includes the Supermaster Series, known for its energy efficiency and precision. The Jetmaster Series caters to large-scale production needs with its robust design. Chen Hsong also provides the Ai Series, which focuses on intelligent injection molding solutions, offering high performance and sustainability.

Unique Selling Points

Chen Hsong distinguishes itself through its focus on technological advancement and customer satisfaction. The company invests heavily in research and development, ensuring that you receive cutting-edge solutions tailored to your needs. Chen Hsong’s machines are renowned for their reliability and efficiency, making them a preferred choice for manufacturers worldwide. Their competitive pricing and extensive service network guarantee that you receive prompt support and maintenance, enhancing your operational efficiency.

Comparison of Top Injection Molding Machine Manufacturers

Product Offerings

When you explore the product offerings of leading injection molding machine manufacturers, you’ll notice a diverse range of machines tailored to meet various industry needs. Haitian, for instance, provides the Mars Series, which is renowned for its energy efficiency and precision. Their Jupiter Series caters to large-scale production, while the Zhafir Series focuses on electric solutions. Milacron offers the Magna Toggle Series for precision and versatility, the Elektron Series for energy-efficient solutions, and the Roboshot Series for all-electric technology. Sumitomo (SHI) Demag features the SE-EV Series for high-speed production and the IntElect Series for energy efficiency. Each manufacturer presents unique products that cater to different manufacturing requirements, ensuring you find a solution that aligns with your specific needs.

Customer Feedback

Customer feedback plays a crucial role in evaluating the performance and reliability of injection molding machines. Users often praise Haitian for its machines’ reliability and efficiency, highlighting their ability to handle high-volume production with minimal downtime. KONGER Machinery receives commendations for its customer-centric approach, offering customizable solutions that meet diverse manufacturing demands. Customers appreciate Sumitomo (SHI) Demag for its precision engineering and energy-efficient machines, which contribute to cost savings and operational efficiency. By considering customer feedback, you can gain valuable insights into the strengths and weaknesses of each manufacturer, helping you make informed decisions.

Differences and Similarities

While each manufacturer offers distinct products and services, there are notable similarities and differences among them. Haitian and Milacron both emphasize innovation and technological advancement, ensuring you receive cutting-edge solutions. However, Haitian focuses more on energy efficiency, while Milacron prioritizes customization. Sumitomo (SHI) Demag shares a commitment to precision and sustainability with its counterparts, yet it stands out with its emphasis on minimizing energy consumption. Despite these differences, all three manufacturers share a dedication to quality and customer satisfaction, providing reliable machines that enhance your manufacturing capabilities.

In this exploration of top injection molding machine manufacturers, you have discovered the unique strengths and offerings of industry leaders like KONGER Machinery, Arburg, and Nissei. Each company excels in innovation, reliability, and customer service, providing solutions tailored to diverse manufacturing needs. Choosing the right manufacturer is crucial for your success. Consider your specific requirements, such as product type and production scale, when selecting a brand. By aligning your needs with the strengths of these manufacturers, you can enhance your operational efficiency and achieve your business goals.

See Also

Strategies For Injection Molding Firms To Boost Competitiveness

Innovating The Injection Molding Sector With Advanced Technology

Current Trends And Future Prospects In Injection Molding

Key Trends Shaping The Two-Plate Injection Molding Machines

Toolots Inc. Explores Advanced Plastic Injection Molding Maker Konger

Post time: Nov-19-2024